What are the steps involved in the production process?

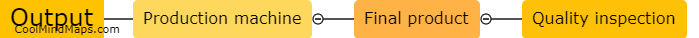

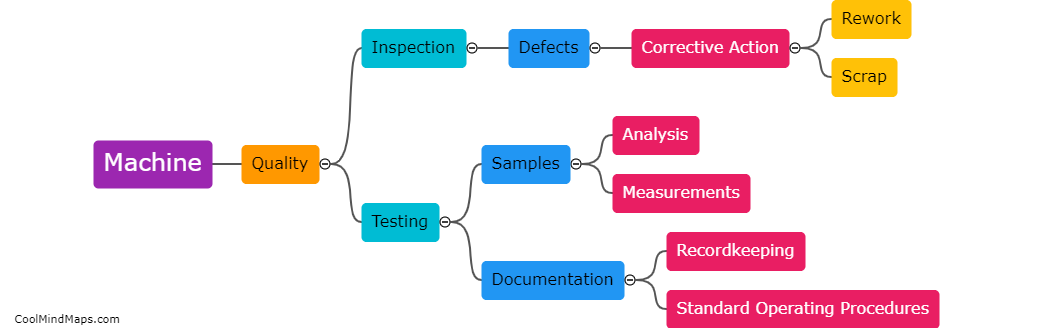

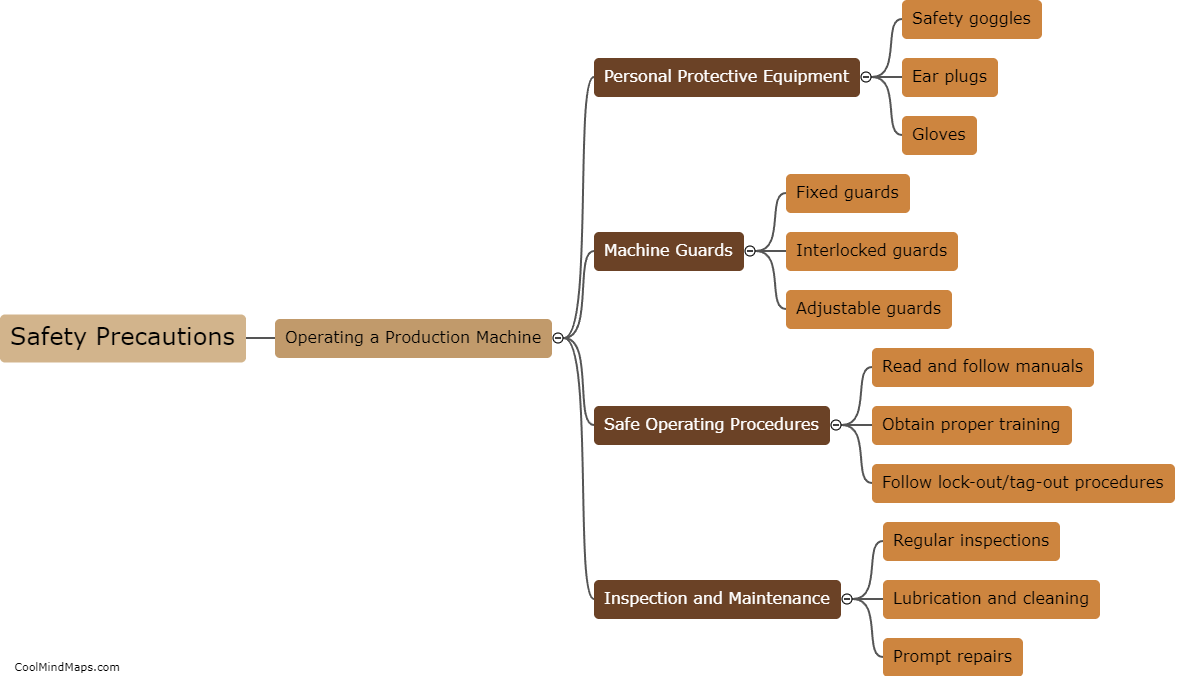

The production process typically involves a series of steps that are followed to convert raw materials or inputs into finished goods or products. These steps may vary depending on the industry and the specific product being manufactured, but some common steps can be identified. First, the planning phase involves determining the product design, creating a production schedule, and identifying the required raw materials and resources. The second step is procurement, where the necessary raw materials and components are sourced and acquired. Then comes the manufacturing phase, where the raw materials are transformed into the final product through various processes such as machining, assembly, or chemical reactions. Quality control and testing are important steps to ensure that the product meets the required specifications. After manufacturing, the products are packaged and prepared for distribution or shipment. Finally, the distribution phase involves storing, transporting, and delivering the finished products to customers. These steps are often interconnected and require effective coordination to ensure a smooth and efficient production process.

This mind map was published on 25 November 2023 and has been viewed 109 times.