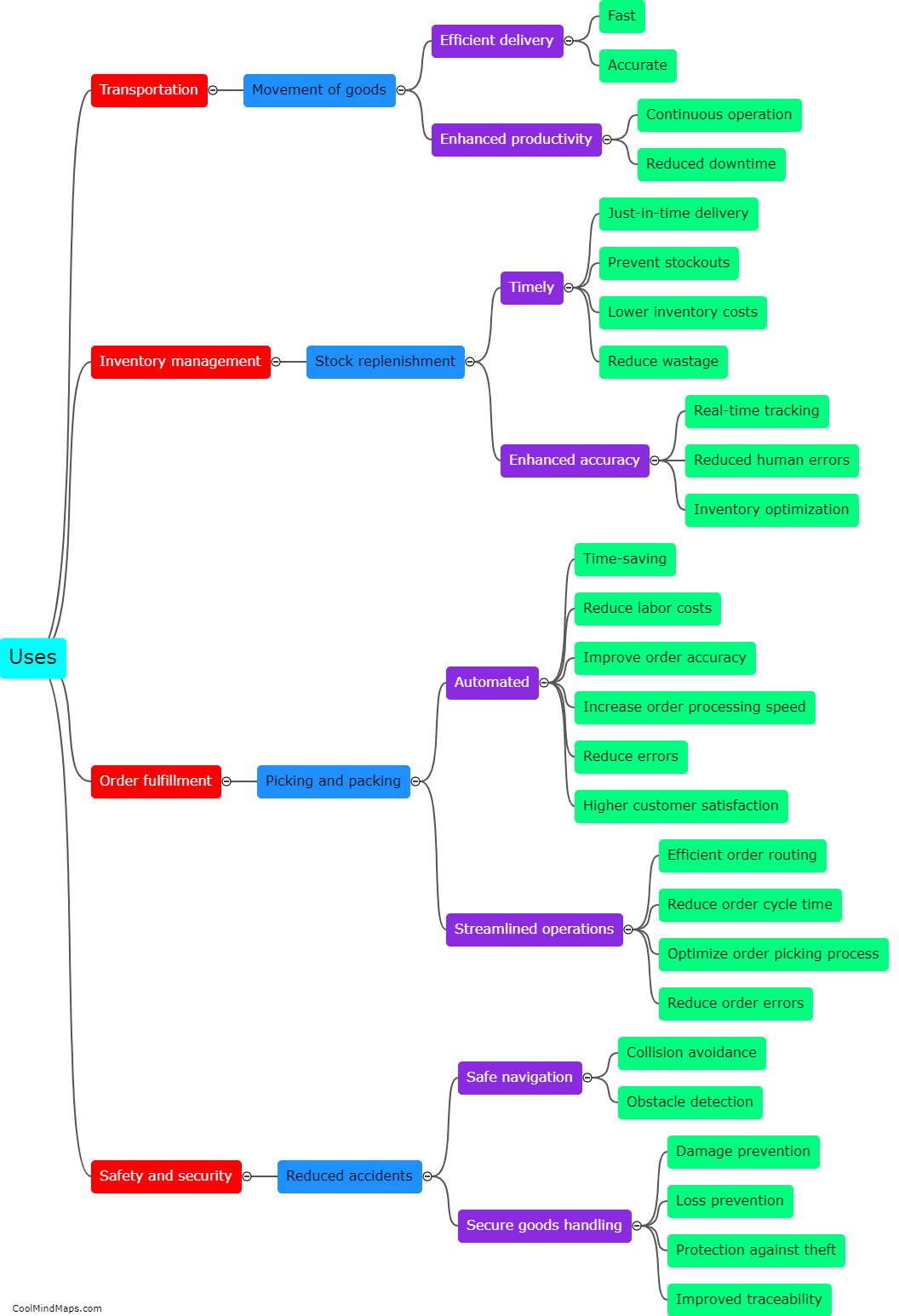

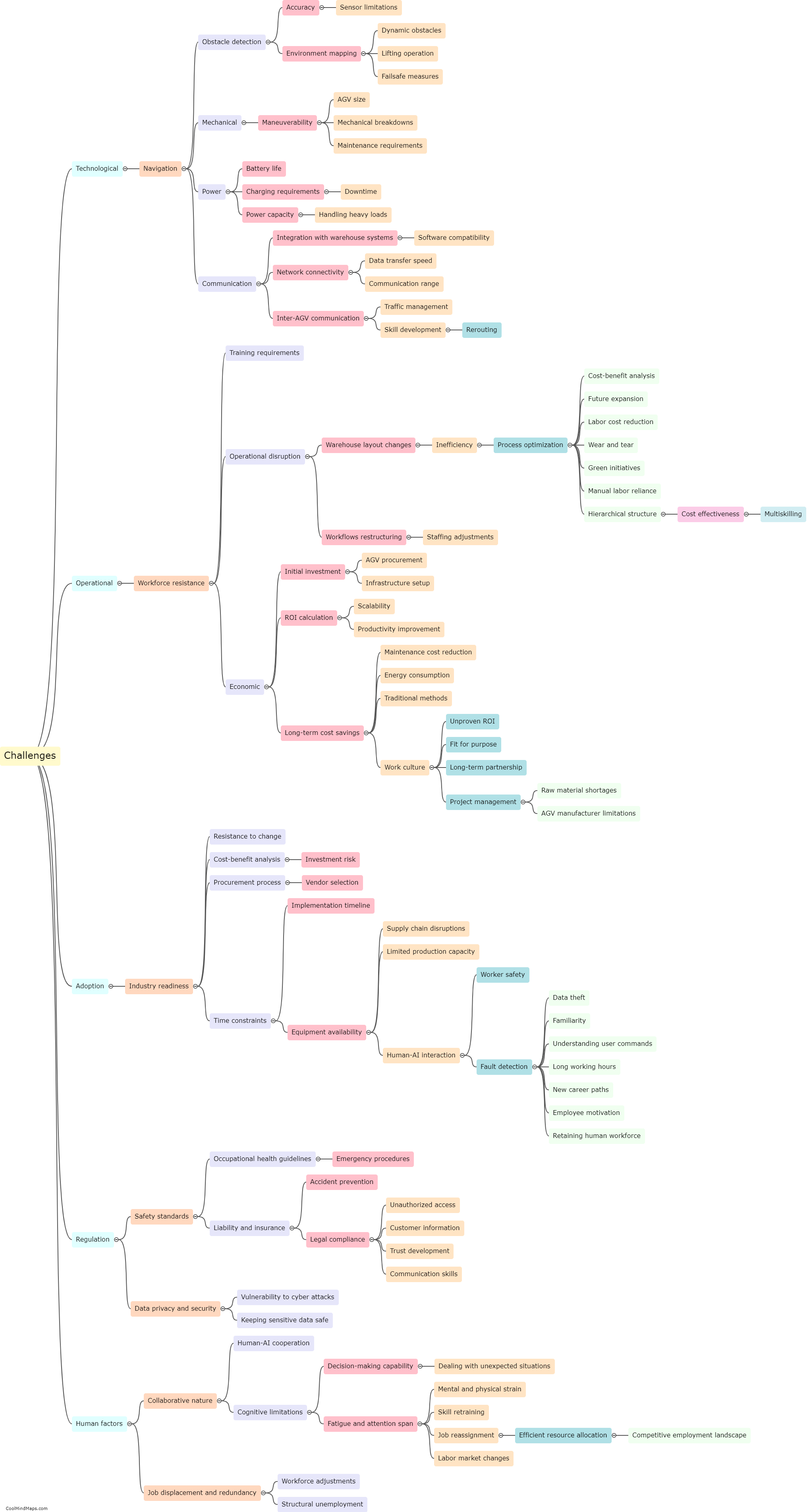

What are the challenges and limitations of implementing AGVs in warehouses?

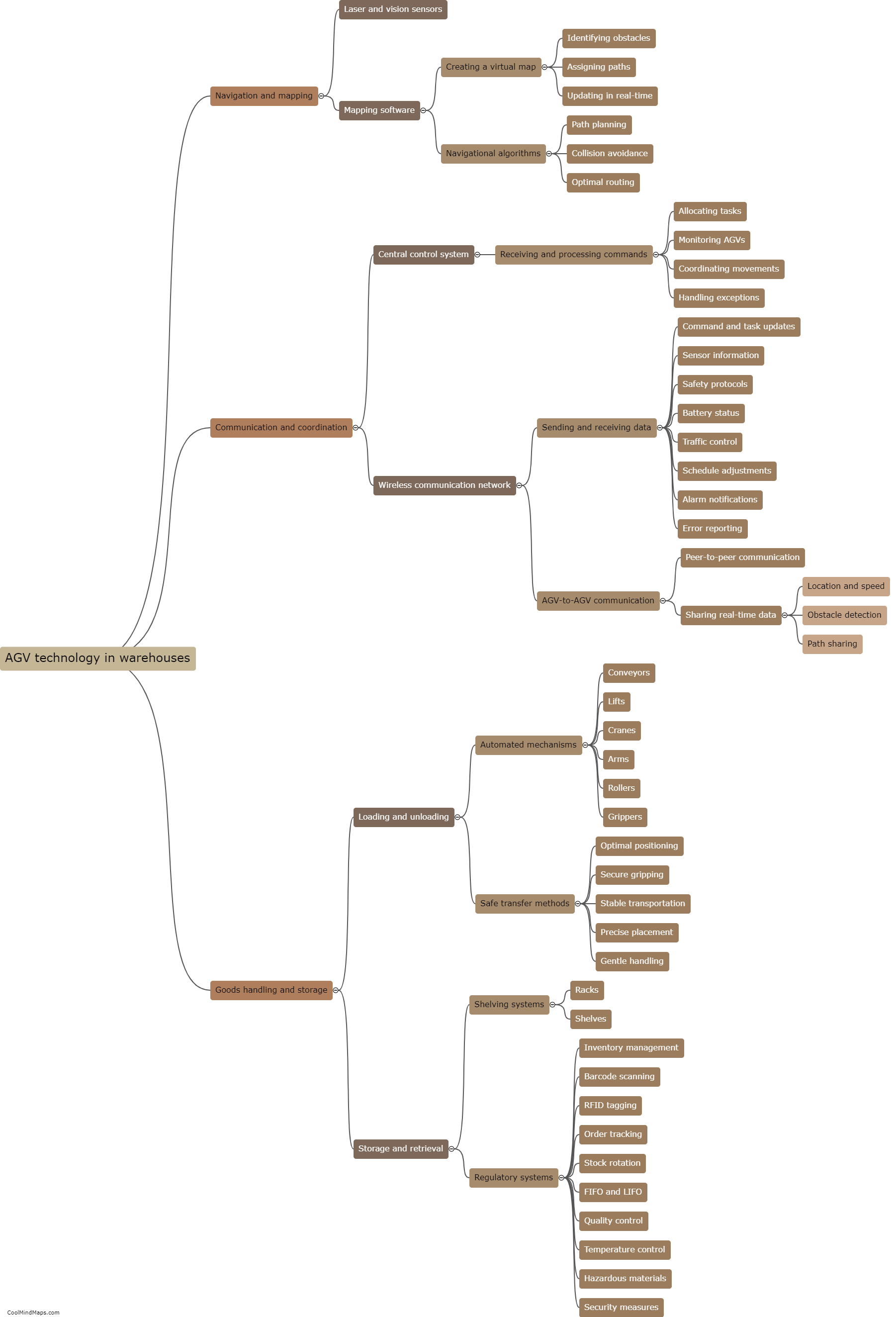

Implementing Automated Guided Vehicles (AGVs) in warehouses certainly brings numerous benefits, but it also entails challenges and limitations. The first challenge lies in the initial investment required to set up the AGV system. The cost of acquiring and integrating AGVs into existing warehouse infrastructure can be significant. Additionally, warehouse layout and design may need to be modified to accommodate AGVs, which may necessitate further expense and effort. Another challenge is the need for skilled technicians to maintain and operate the AGV fleet. Training employees to handle AGVs effectively and safely can be time-consuming and costly. Moreover, AGVs may face limitations in terms of flexibility and adaptability. They are best suited for repetitive and predictable tasks, such as simple material transportation, whereas complex warehouse processes may still require human intervention. Furthermore, AGVs might struggle with navigating dynamically changing environments or overcoming physical obstacles. These challenges highlight the need for careful planning, investment, and consideration of the limitations to successfully implement AGVs in warehouses.

This mind map was published on 17 January 2024 and has been viewed 81 times.