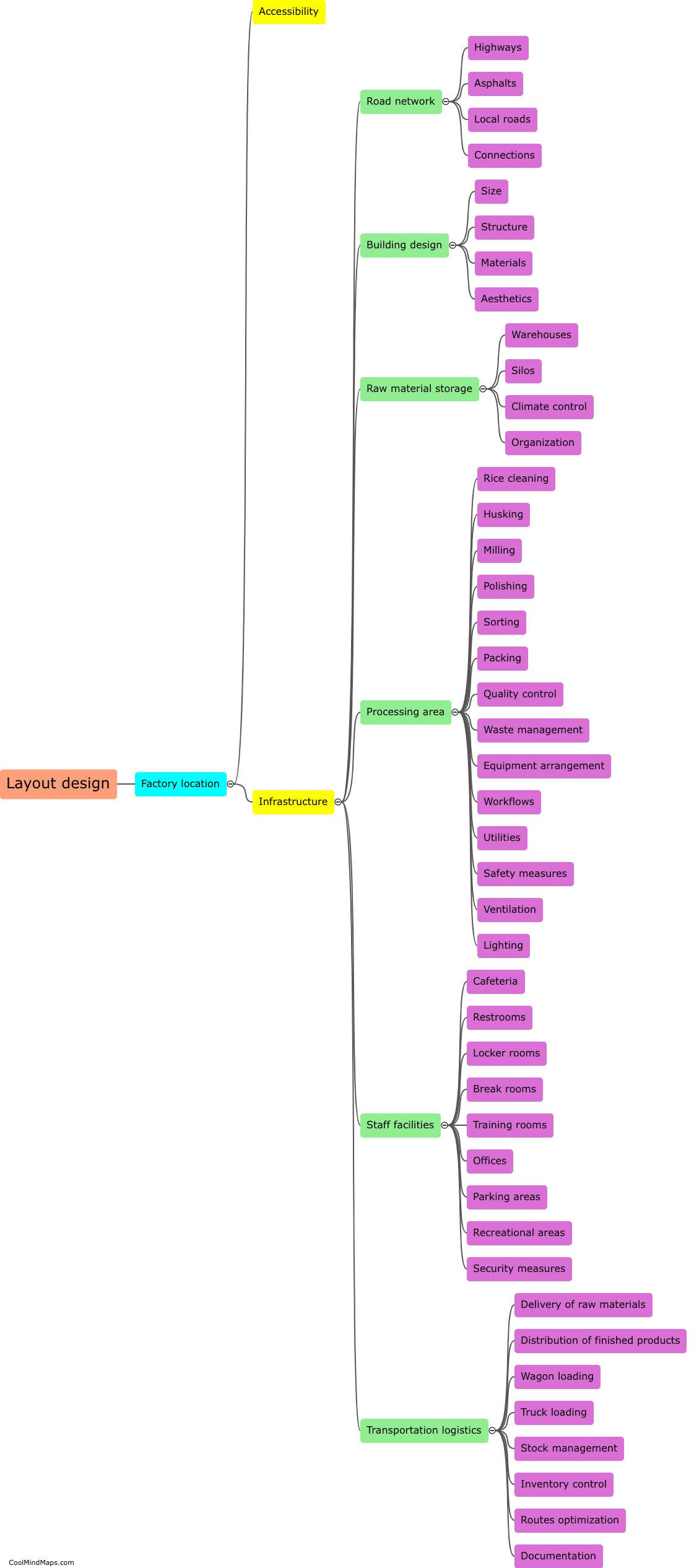

How to design an efficient layout for a rice milling factory?

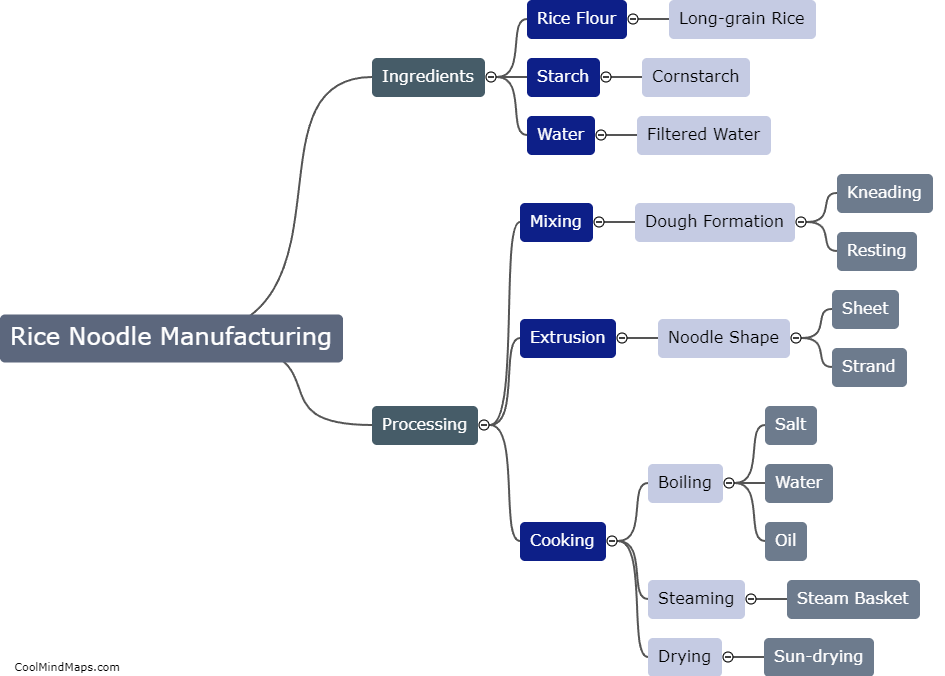

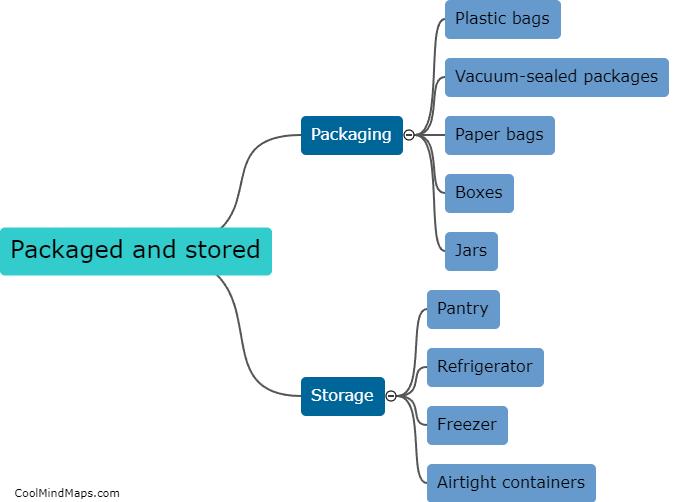

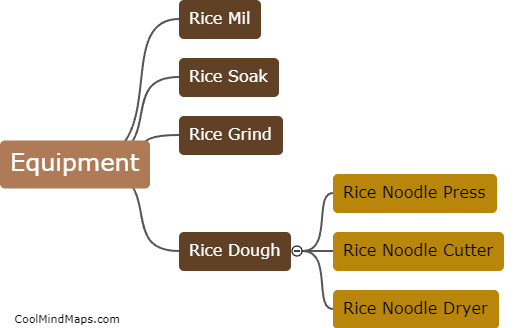

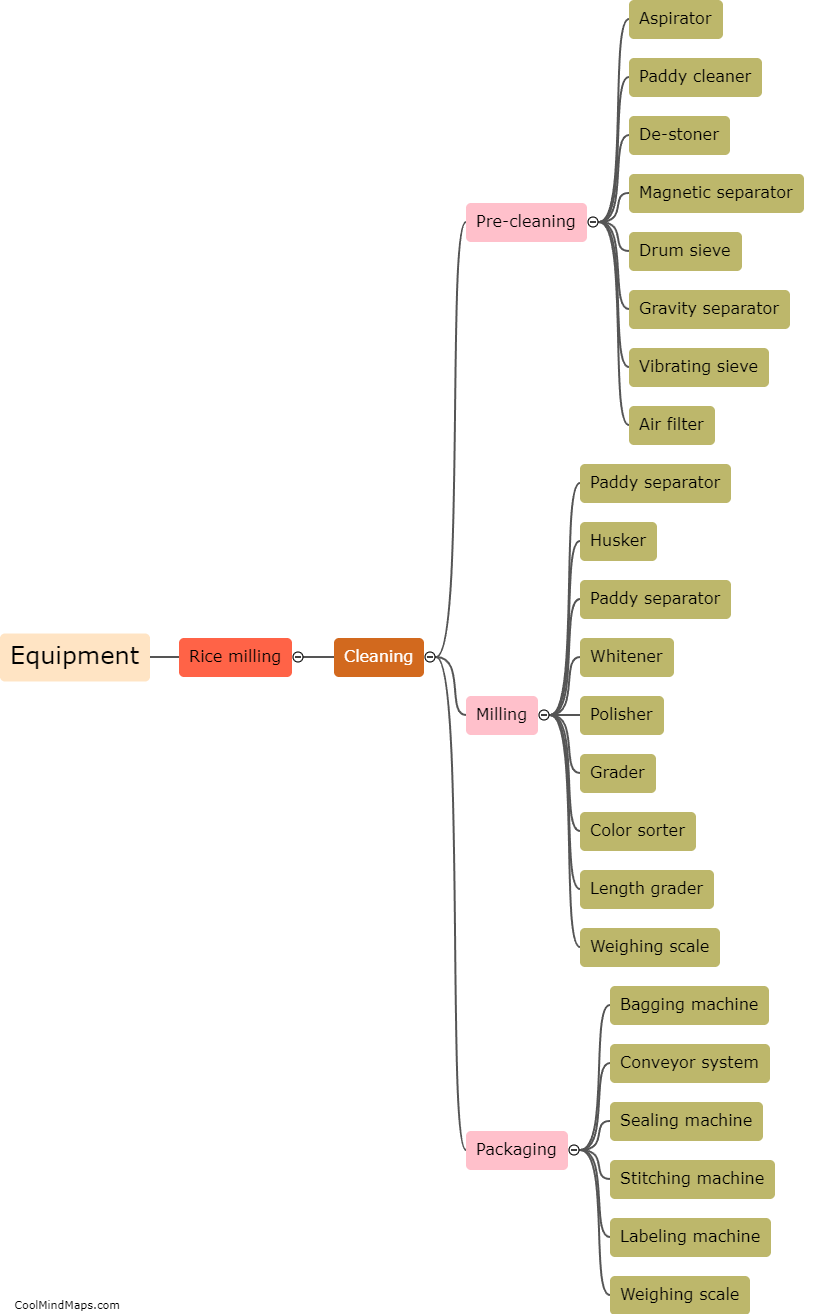

Designing an efficient layout for a rice milling factory involves careful planning and consideration of various factors. Firstly, the layout should ensure a smooth flow of operations, from the arrival of raw paddy to the packaging and distribution of milled rice. This can be achieved by strategically positioning processing equipment like cleaners, huskers, and whitening machines in a sequential order. Additionally, the layout should prioritize safety and sanitation, providing adequate space for workers to maneuver and maintain hygiene standards. Furthermore, proper storage facilities for both raw and processed rice should be incorporated to minimize wastage and facilitate easy access for transportation. Finally, the layout should accommodate future expansion or modifications, offering flexibility to incorporate new technologies and processes as needed. Overall, a well-designed layout for a rice milling factory can enhance productivity, quality, and profitability.

This mind map was published on 30 July 2023 and has been viewed 105 times.