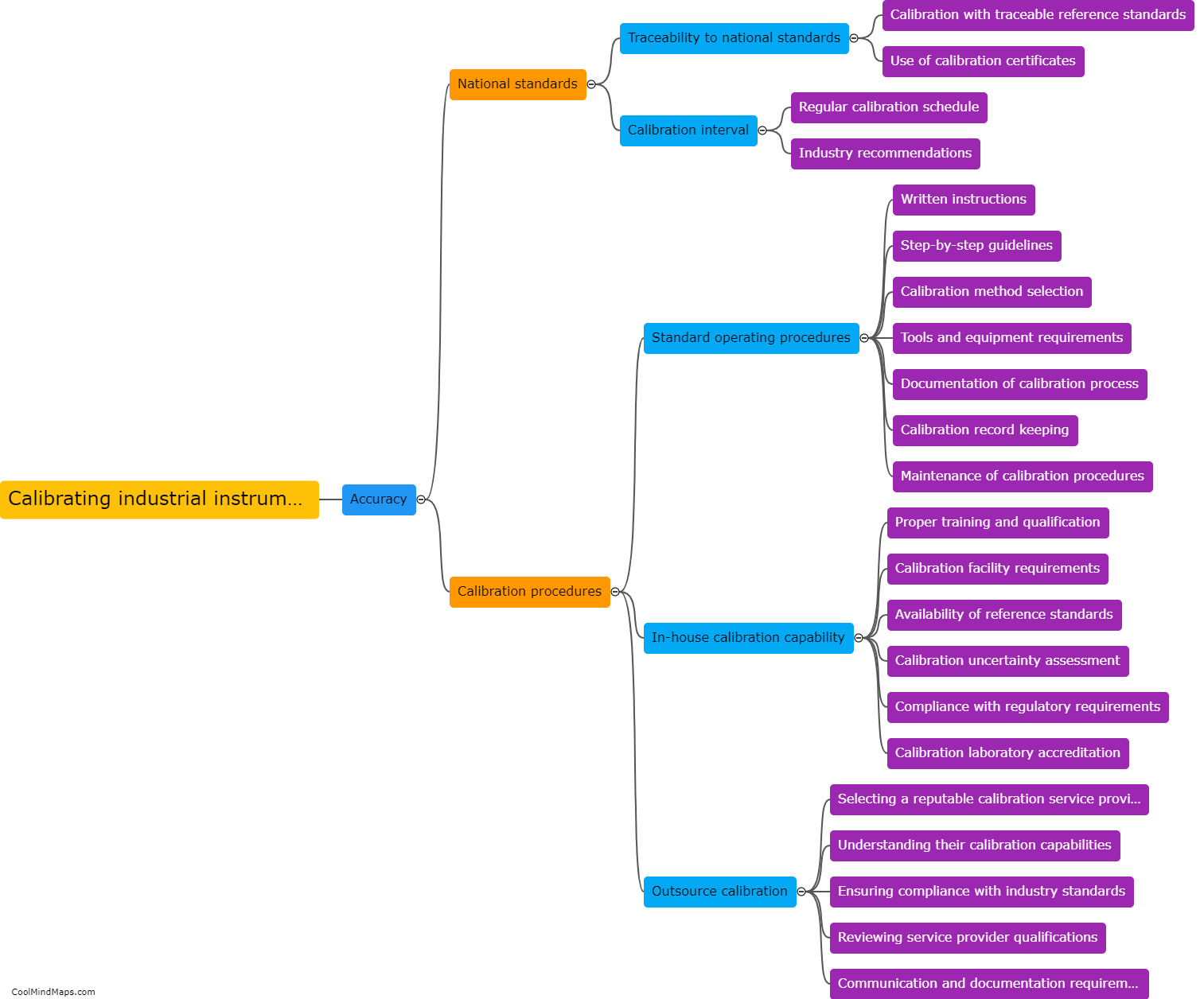

What are the common standards to follow for calibrating industrial instruments?

Calibrating industrial instruments is crucial to ensure accurate measurements and reliable performance. There are several common standards that organizations typically follow when calibrating these instruments. The International Organization for Standardization (ISO) provides standards, such as ISO 9001, which establishes quality management systems that include calibration protocols. Additionally, the National Institute of Standards and Technology (NIST) in the United States provides traceability standards that ensure measurements are linked to a recognized standard. Organizations may also adhere to specific industry standards, like those set by the American National Standards Institute (ANSI) or the International Electrotechnical Commission (IEC). These standards ensure consistent calibration practices, documentation, and traceability, ultimately promoting accuracy, reliability, and compliance with regulatory requirements in industrial settings.

This mind map was published on 2 July 2023 and has been viewed 96 times.