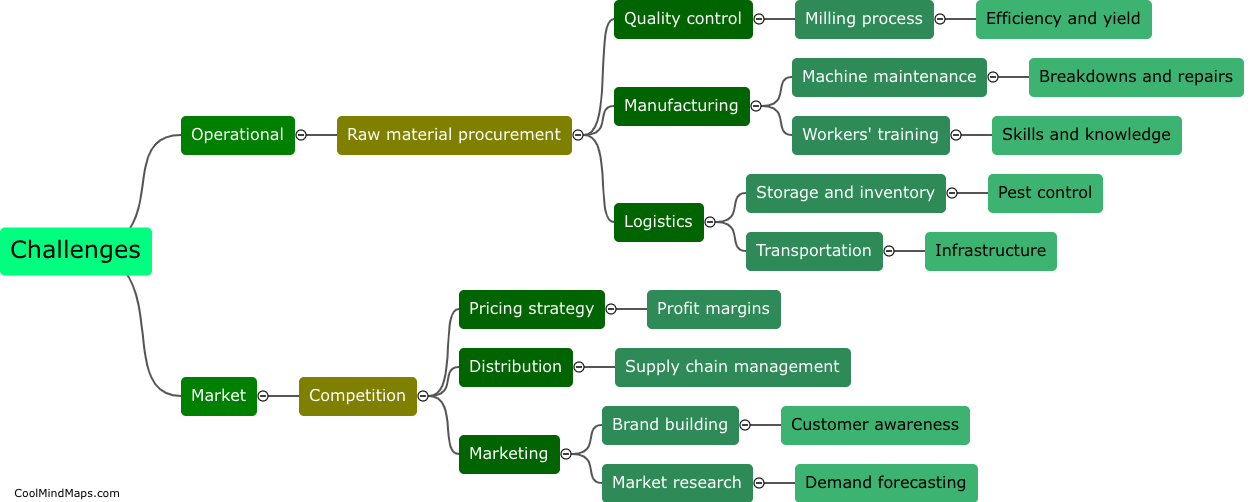

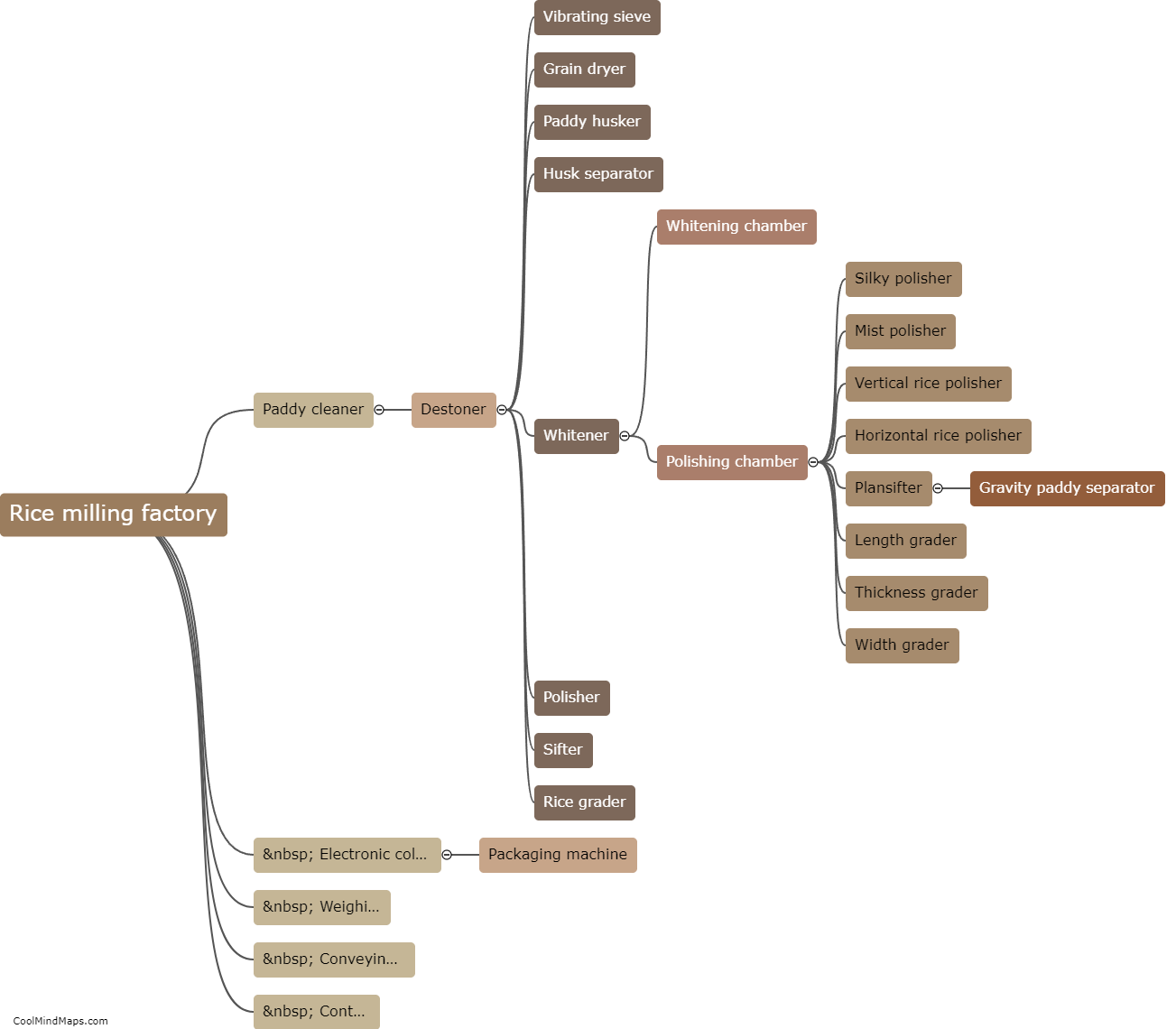

What equipment is needed in a rice milling factory?

In a rice milling factory, various types of equipment are required to efficiently process and produce high-quality rice. Some essential equipment includes a paddy separator, which separates the husk and paddy from the raw harvested rice; a de-stoner, which removes stones and other impurities from the rice; a husker, which removes the husk from the paddy; and a whitening machine, which removes the bran layer from the rice kernel. Other important equipment includes a color sorter to remove any discolored or defective grains, a polisher to enhance the appearance of the rice, and a grading machine to sort the rice according to size. Additionally, storage silos, conveyors, and packaging machines are necessary for storing and packaging the processed rice. Overall, a variety of equipment is needed to ensure the efficient and quality processing of rice in a milling factory.

This mind map was published on 2 August 2023 and has been viewed 97 times.