How does CFD help optimize cutting parameters in metal machining?

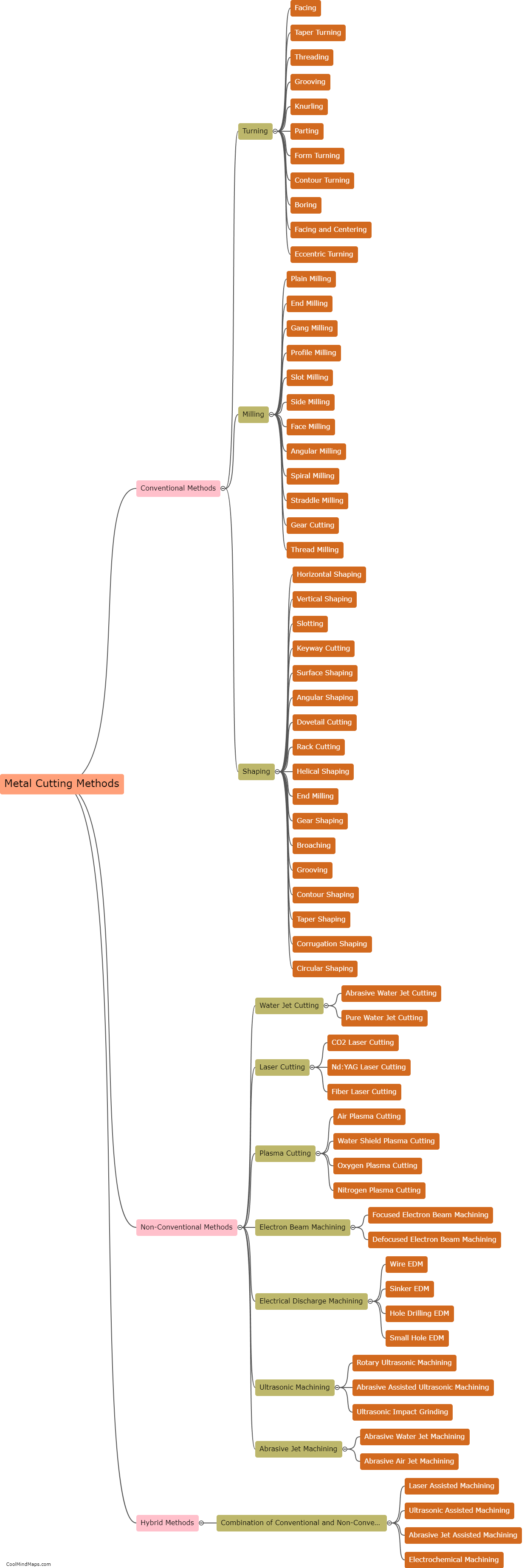

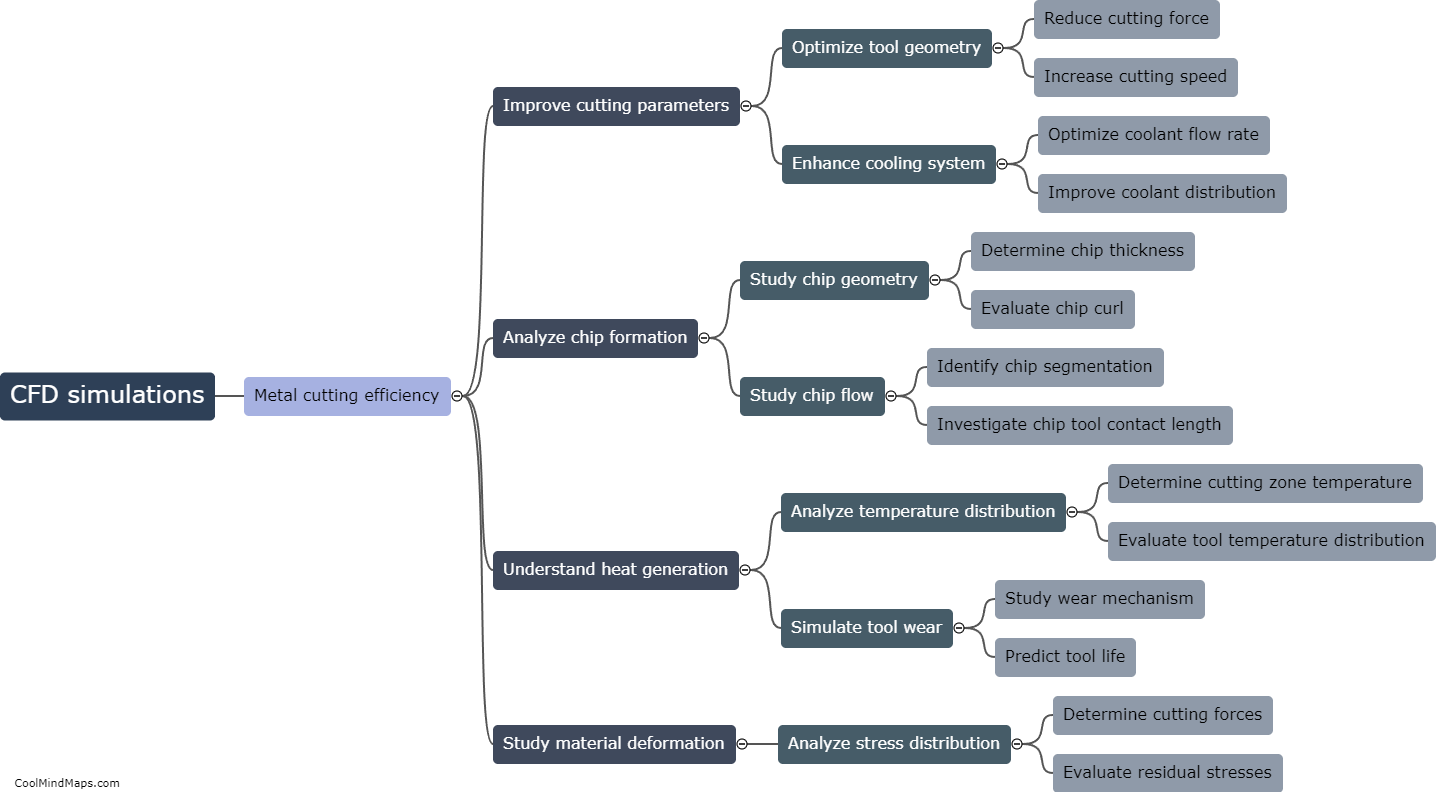

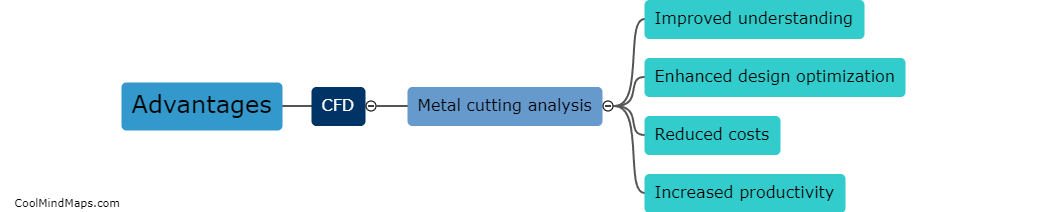

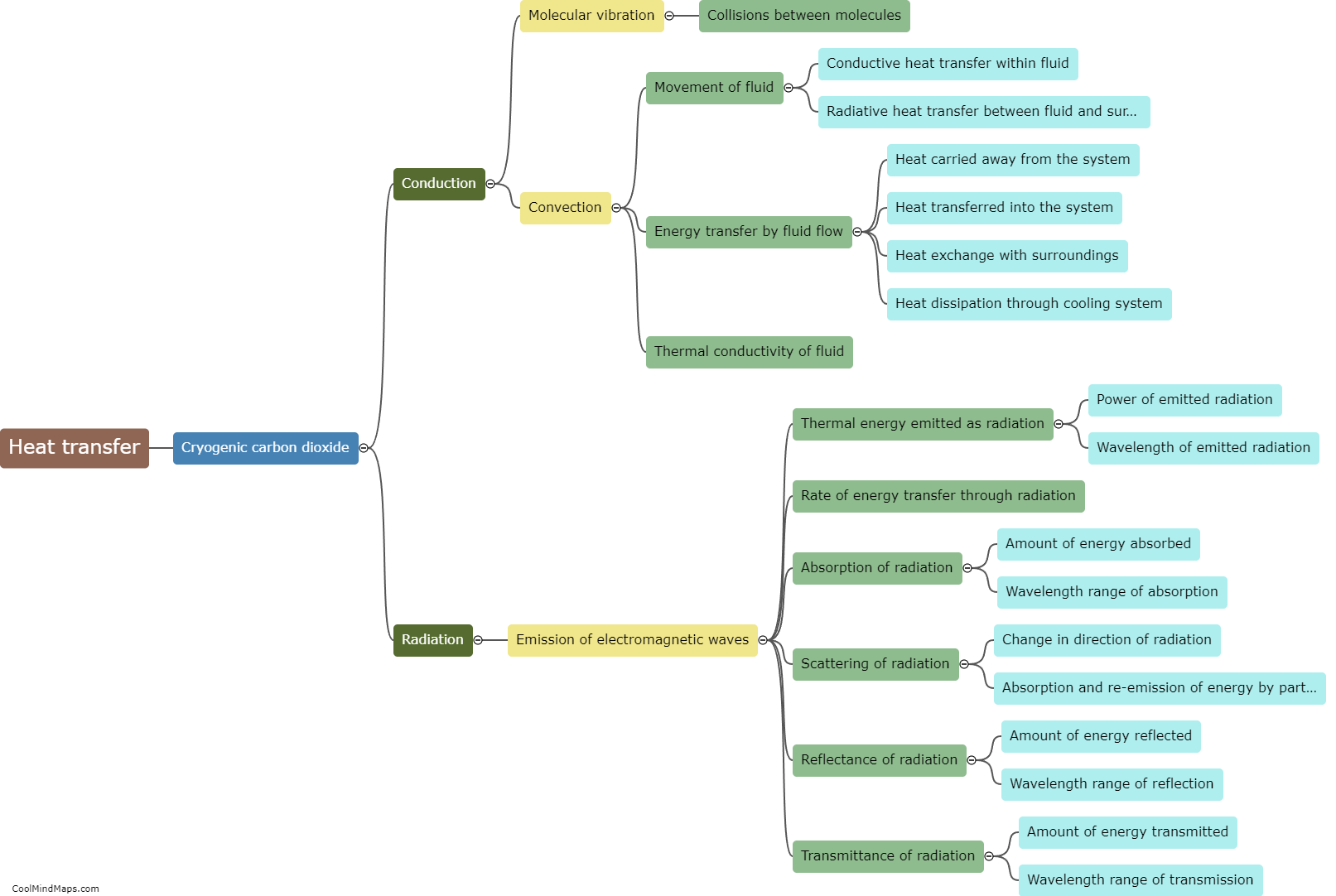

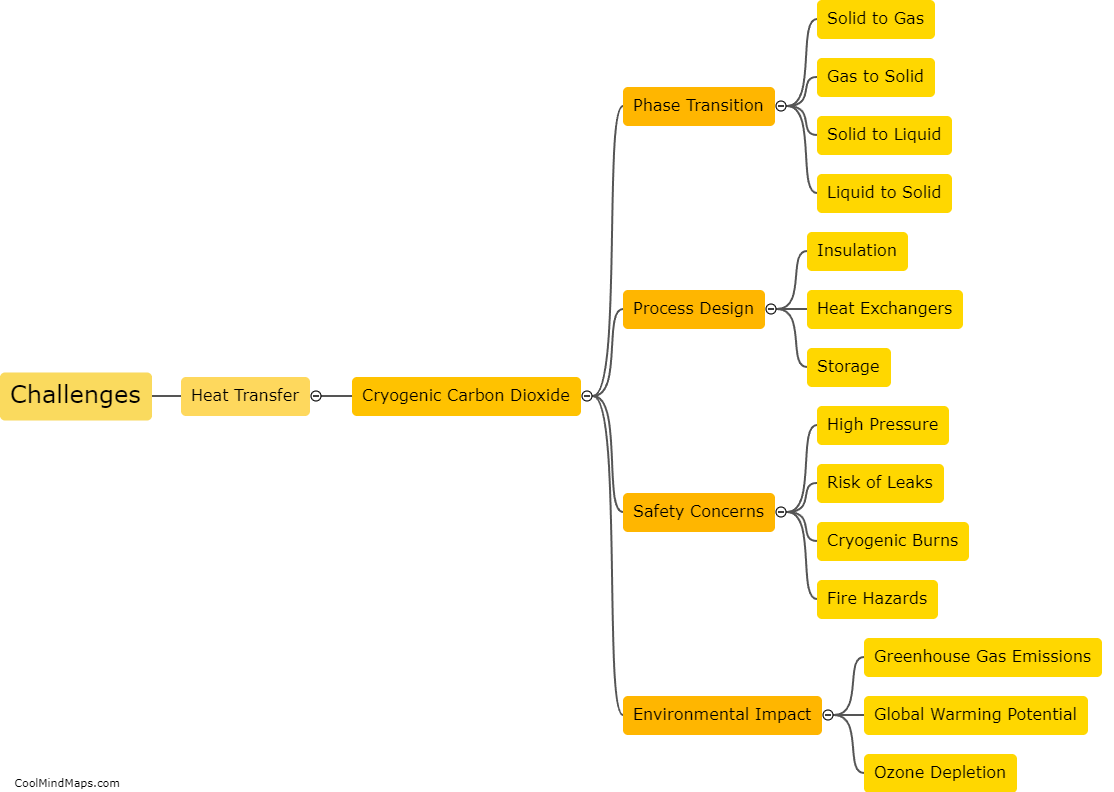

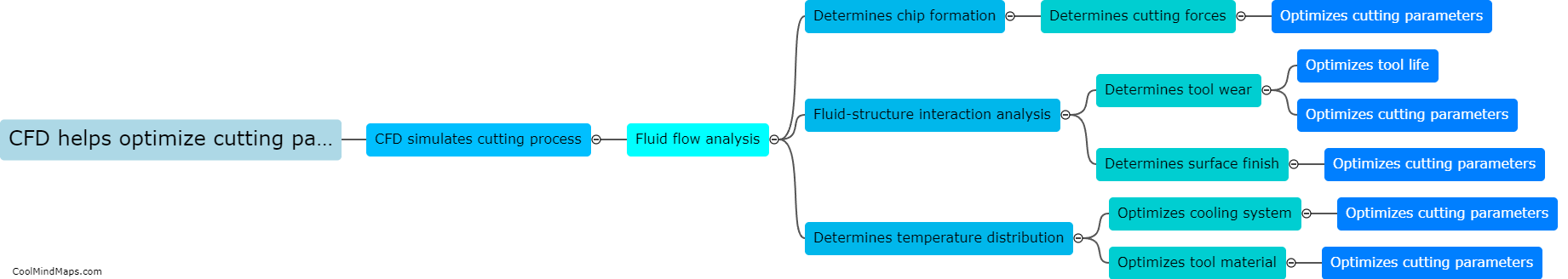

Computational Fluid Dynamics (CFD) is a valuable tool that helps optimize cutting parameters in metal machining processes. By simulating and analyzing the fluid flow, heat transfer, and material removal within the cutting zone, CFD provides insights into the complex interactions between the cutting tool, workpiece, and coolant. It allows engineers to make informed decisions on crucial parameters such as cutting speed, feed rate, and depth of cut. CFD simulations help evaluate different scenarios, predict chip formation characteristics, and identify potential issues such as excessive heat generation or poor chip evacuation. Ultimately, by accurately modeling the machining process, CFD aids in optimizing cutting parameters to enhance productivity, minimize tool wear, and improve surface finish in metal machining operations.

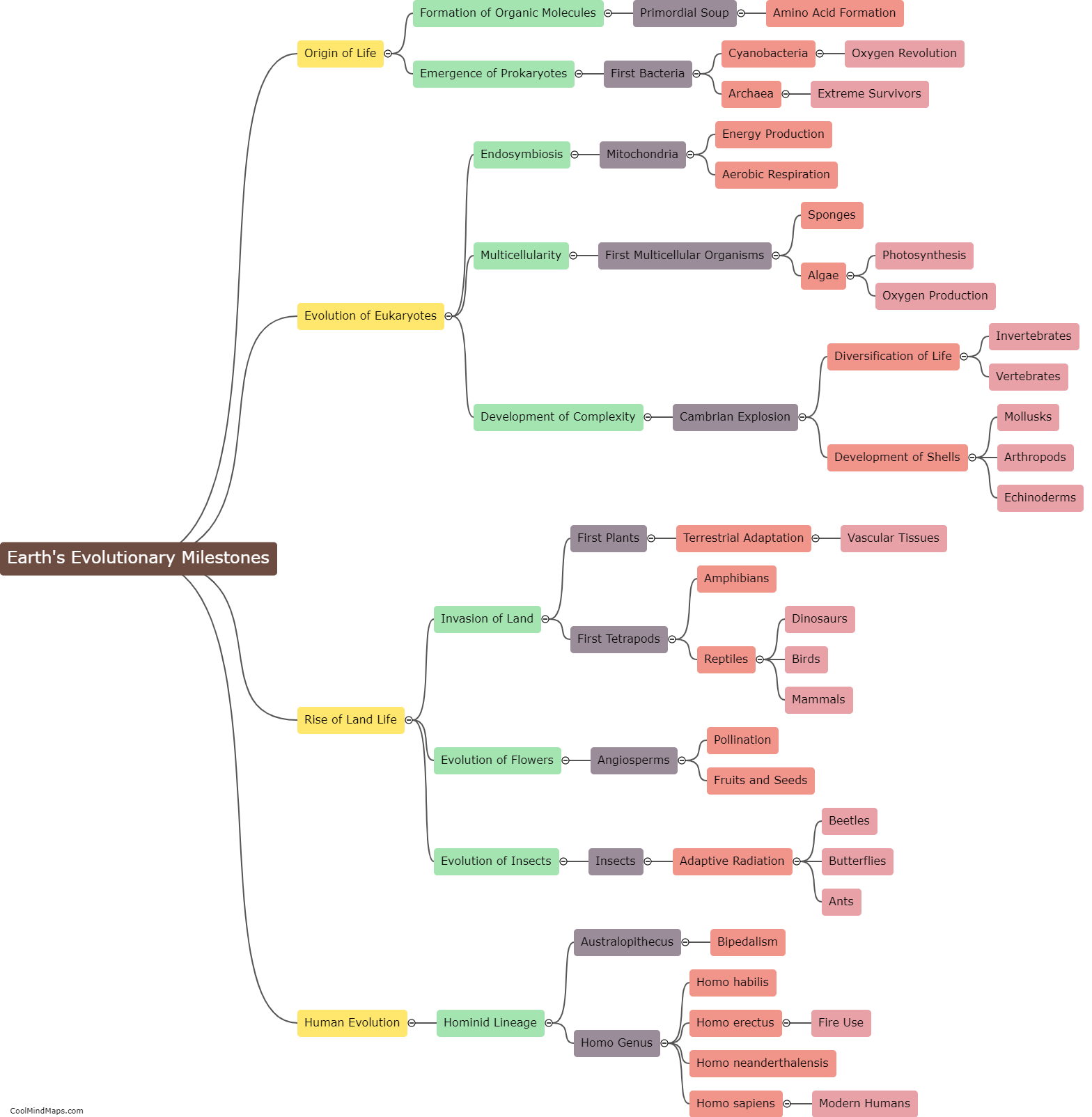

This mind map was published on 30 December 2023 and has been viewed 89 times.