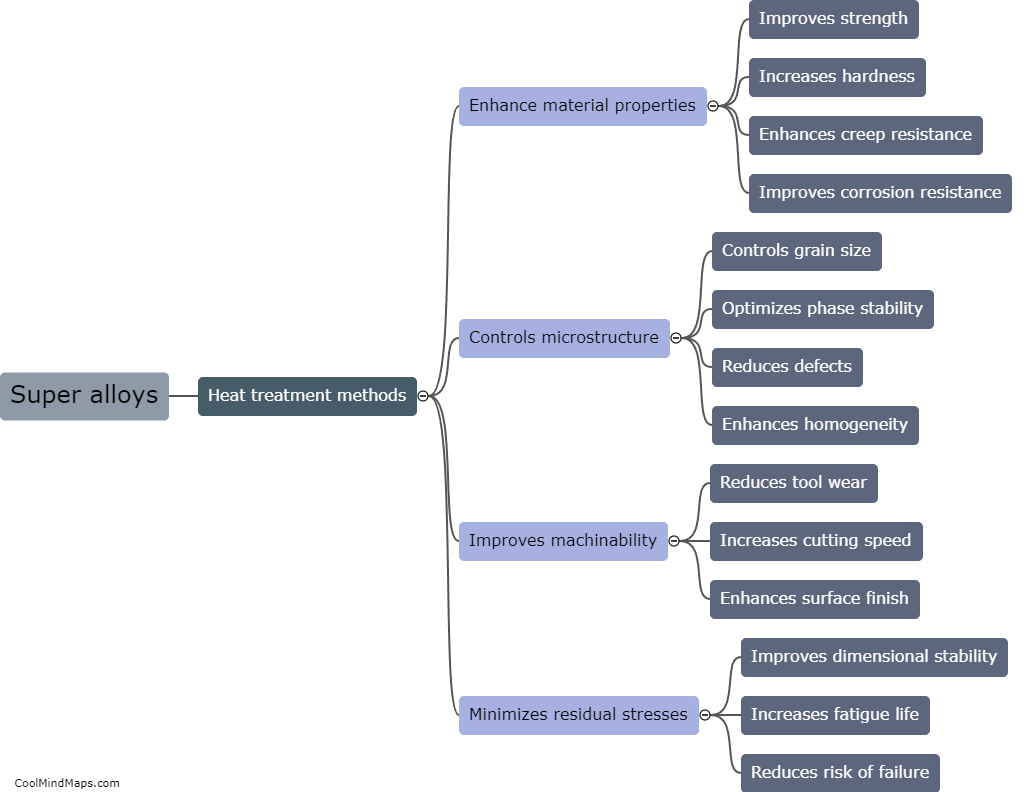

Why are heat treatment methods important for super alloys?

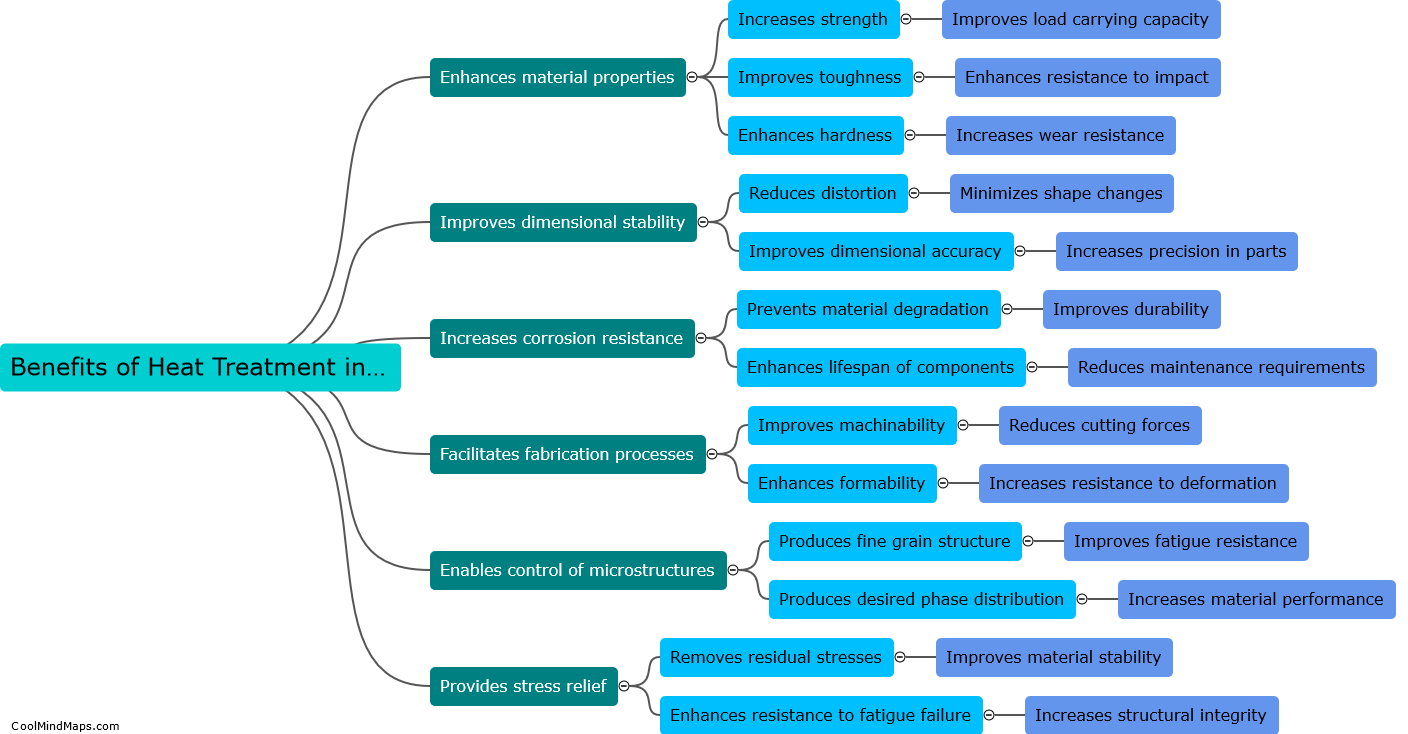

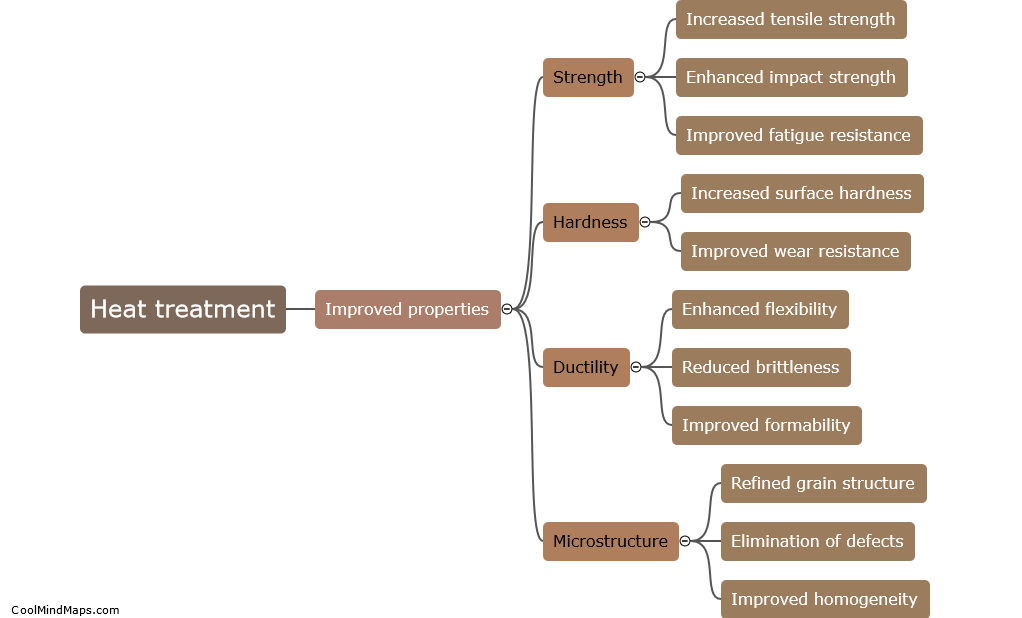

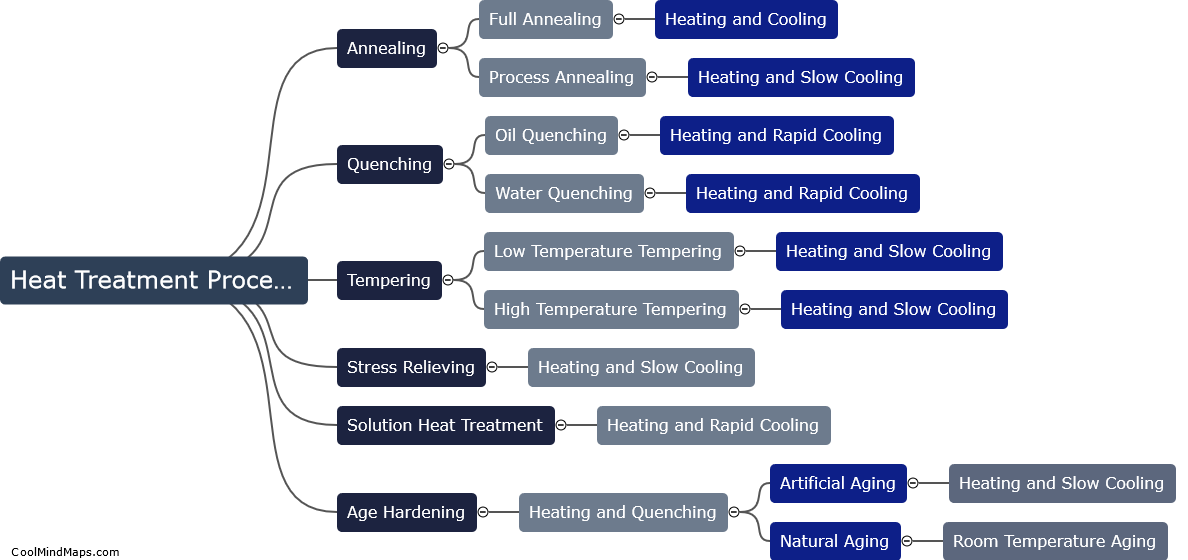

Heat treatment methods are crucial for super alloys due to their unique compositions and performance requirements. These alloys are designed to exhibit exceptional strength, toughness, and resistance to extreme temperatures, corrosion, and stress. Heat treatment allows for the optimization of these material properties by carefully controlling the heating and cooling cycles. It helps in refining the microstructure, eliminating impurities, and enhancing the alloy's mechanical and metallurgical qualities. By undergoing heat treatment, super alloys can achieve their desired high-performance characteristics, making them suitable for demanding applications such as aircraft engines, gas turbines, and nuclear reactors.

This mind map was published on 31 August 2023 and has been viewed 104 times.