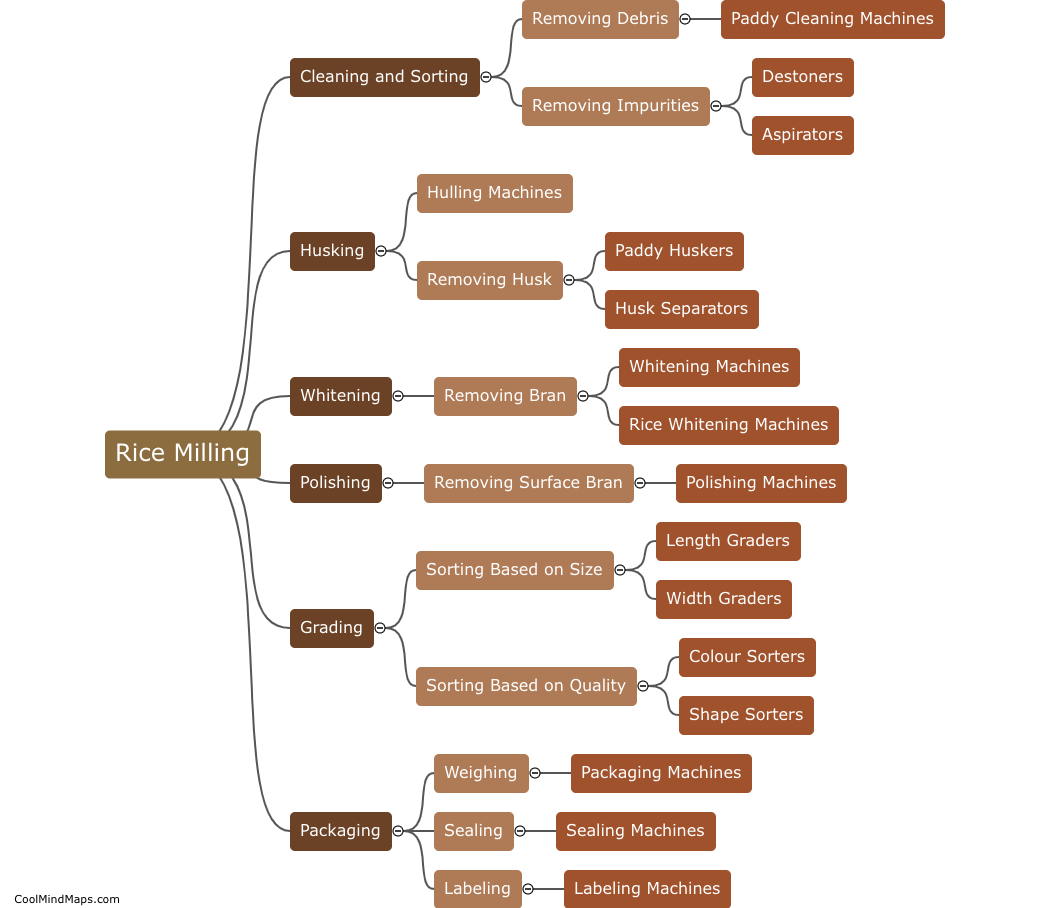

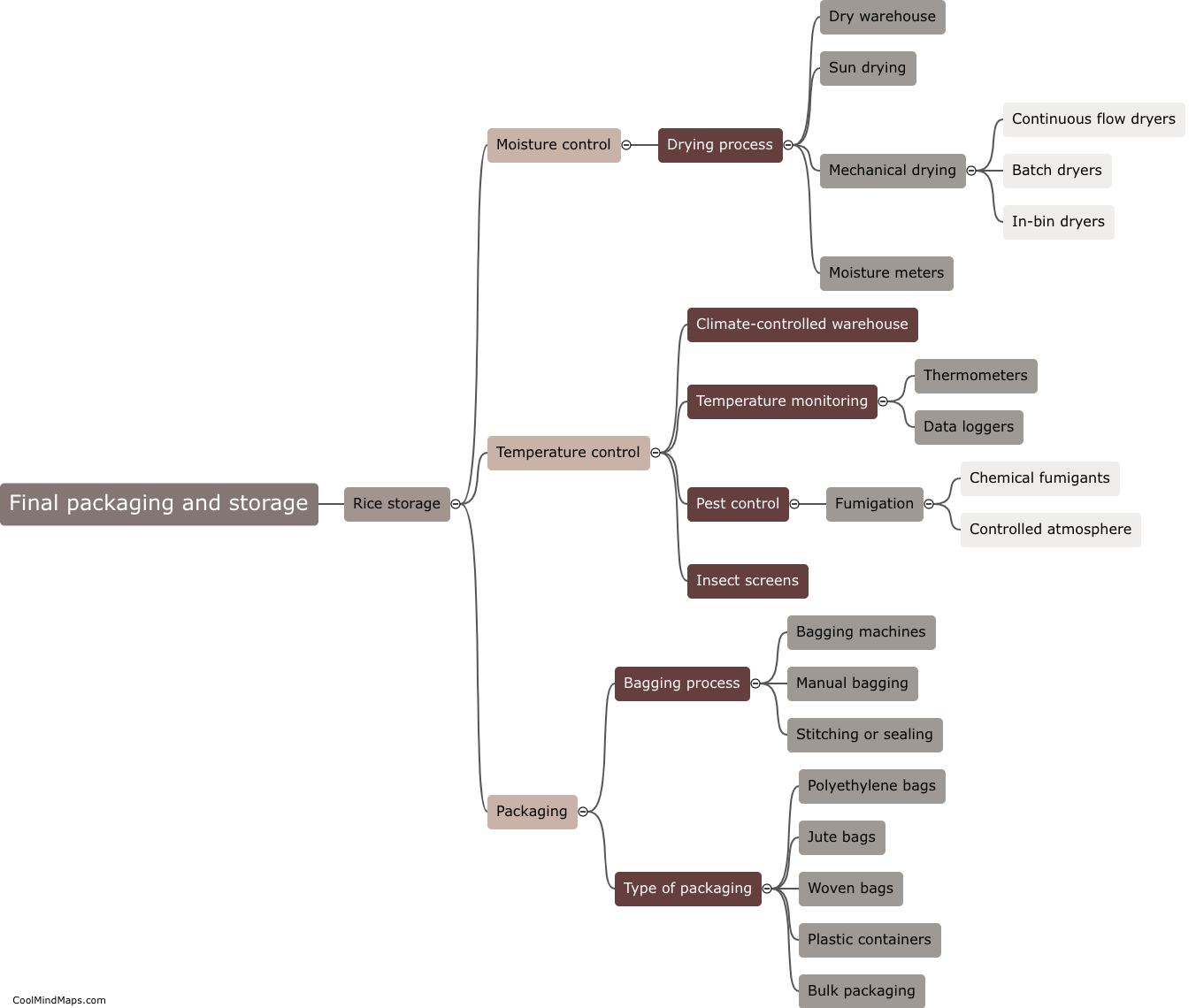

What are the final packaging and storage steps in rice milling?

The final packaging and storage steps in rice milling are crucial to ensure the quality and longevity of the product. After the rice is milled and broken grains are removed, it goes through the packaging process. The rice is typically packaged in bags, which are commonly made of plastic, and can vary in sizes depending on the intended market. These bags are sealed to prevent moisture and pests from entering. Additionally, some rice milling facilities may opt for more advanced packaging techniques such as vacuum sealing to extend the shelf life of the rice. Once packaged, the rice is then stored in a controlled environment to maintain its freshness and prevent spoilage. Temperature and humidity levels are carefully regulated to minimize the growth of mold or bacteria. Proper packaging and storage ensure that the rice reaches consumers in optimal condition and enhances its shelf life.

This mind map was published on 30 July 2023 and has been viewed 106 times.