What are the advantages of using CFD in metal cutting analysis?

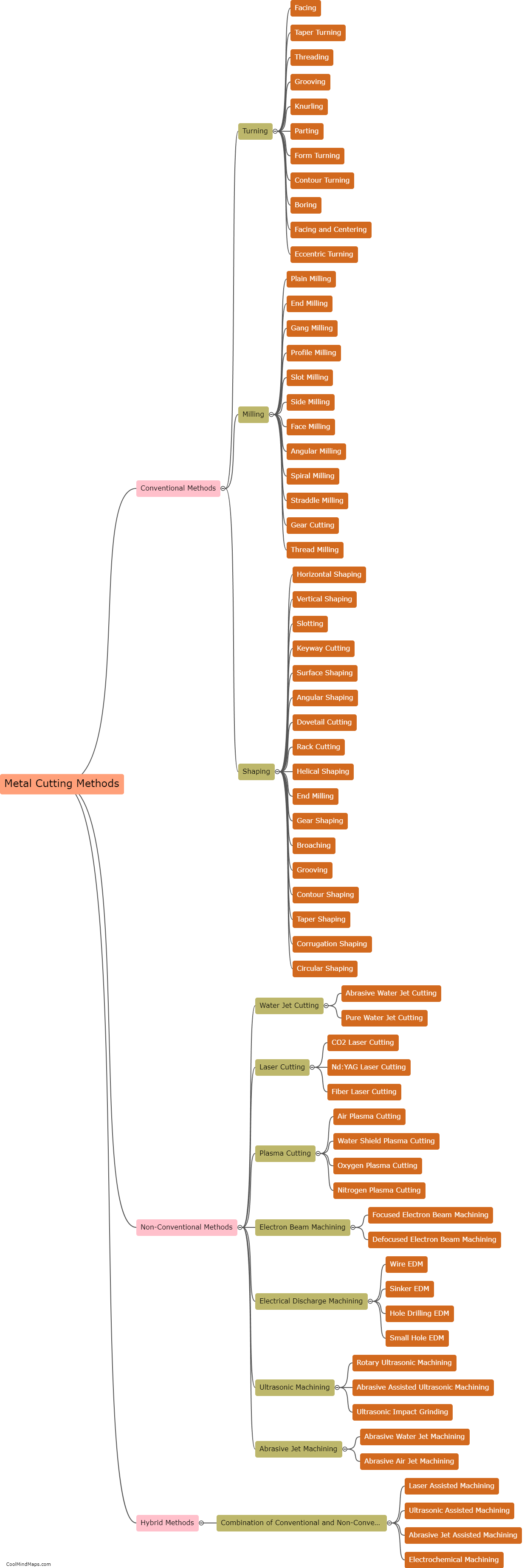

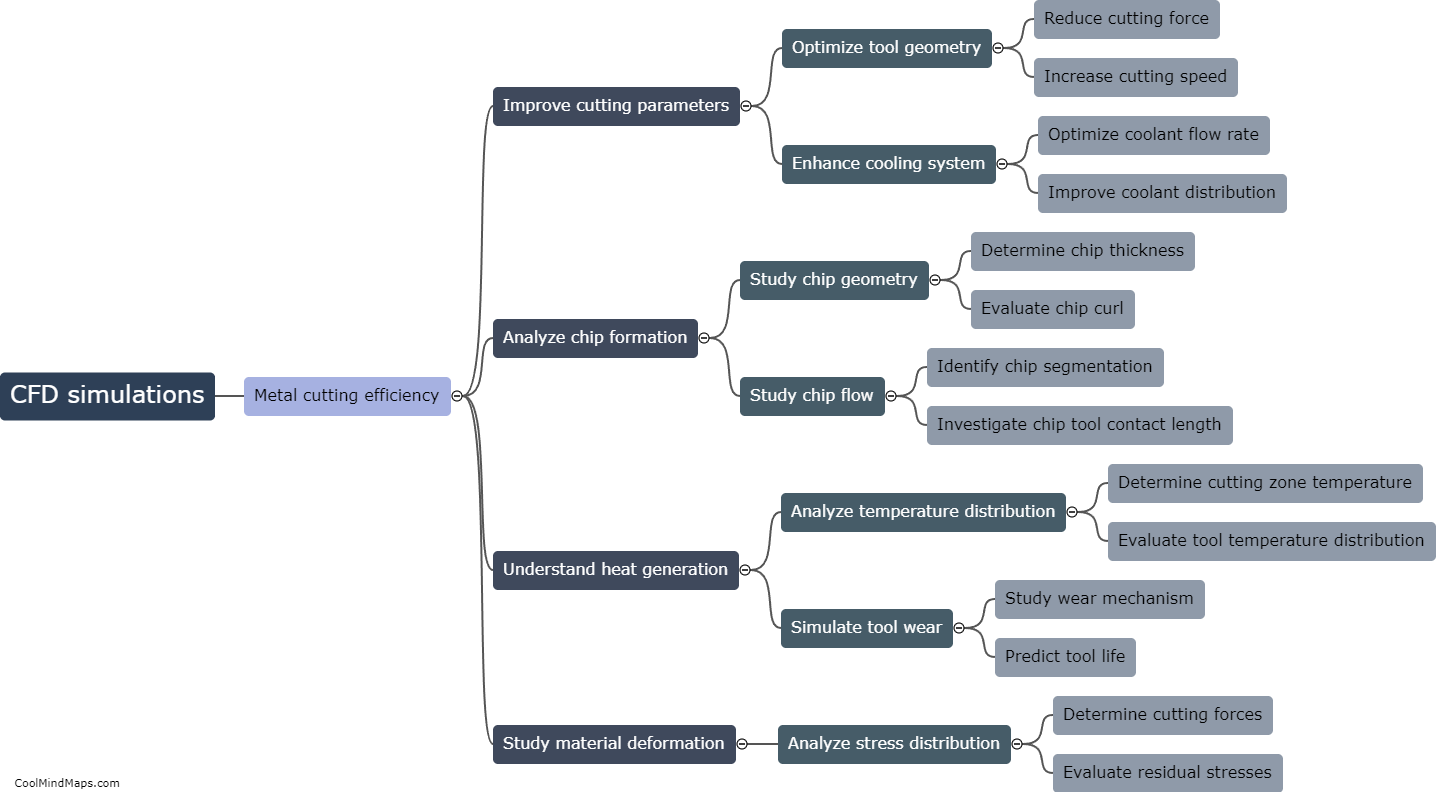

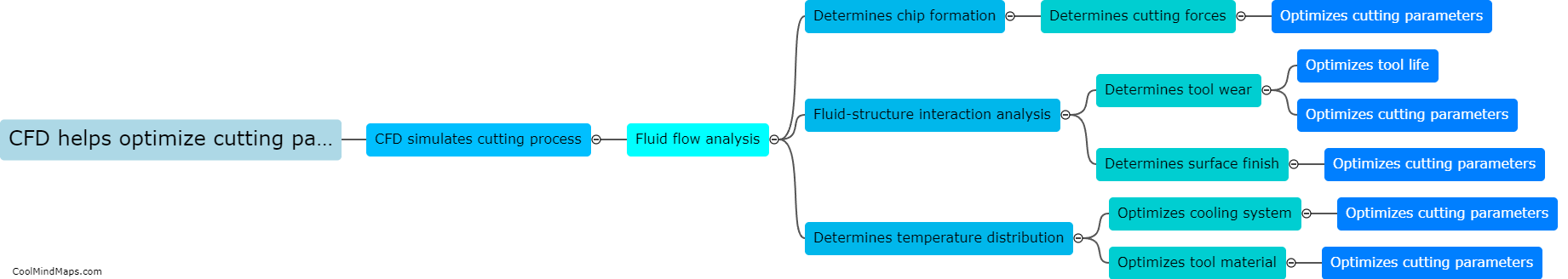

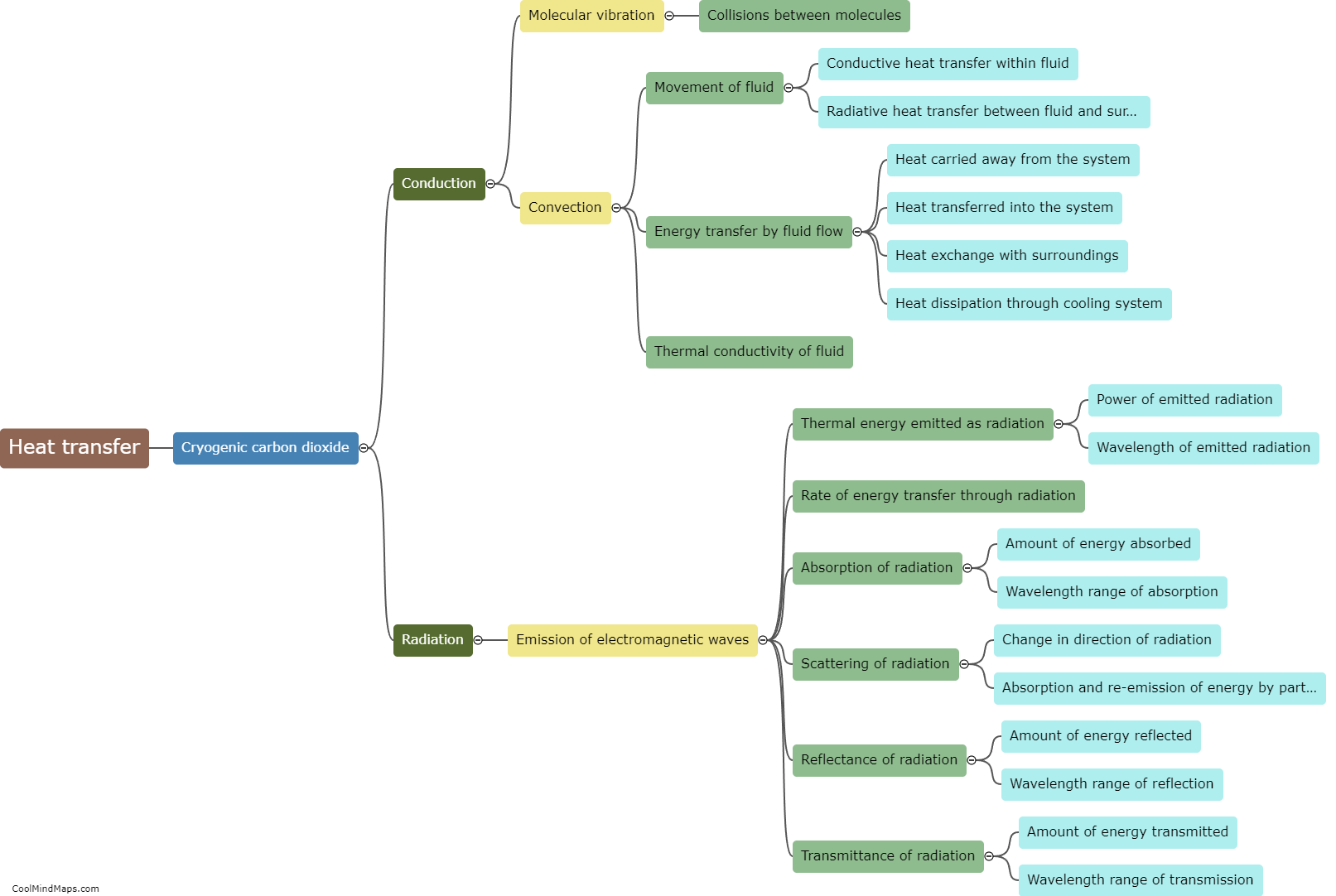

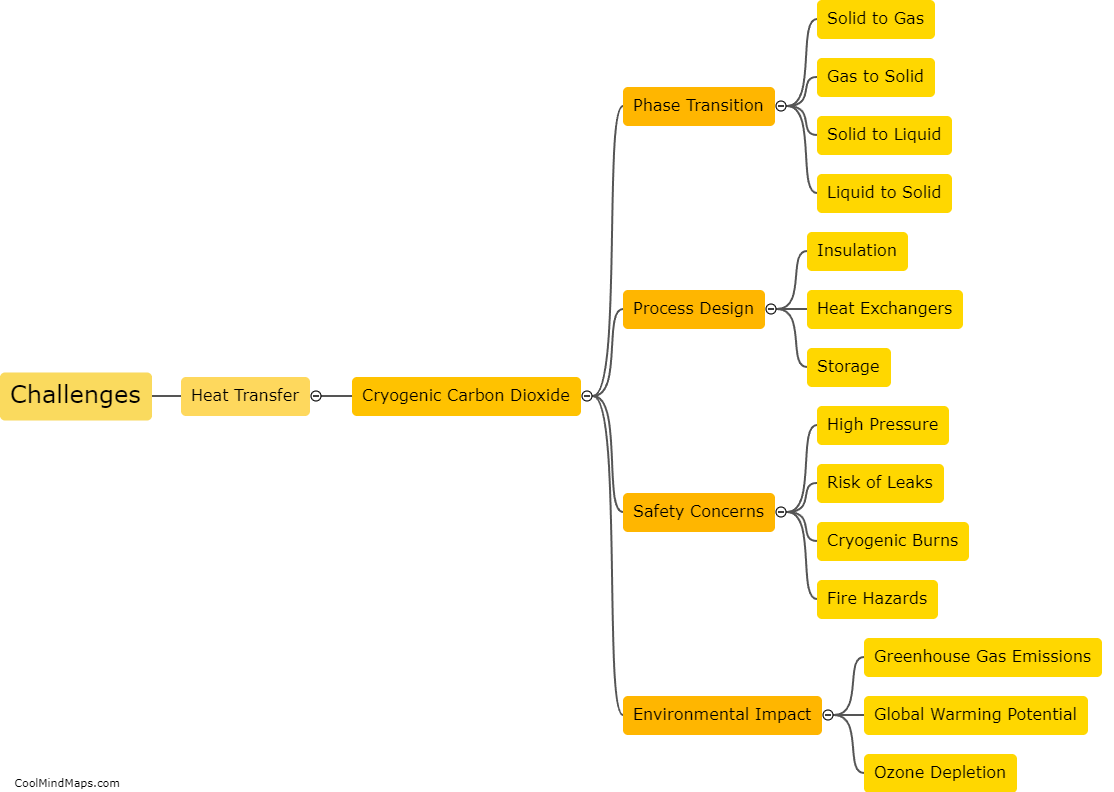

Computational Fluid Dynamics (CFD) is a powerful tool that can be extremely beneficial in analyzing metal cutting processes. Firstly, CFD allows for a detailed understanding of the fluid flow and heat transfer phenomena that occur during metal cutting. It helps to identify the regions of high temperature, velocity, and pressure, which are crucial factors affecting tool wear, surface finish, and chip formation. Secondly, CFD provides a cost-effective and time-efficient platform for evaluating different cutting parameters, tool geometries, and coolant strategies before conducting physical experiments. It enables the optimization of cutting conditions, leading to enhanced productivity, reduced tool wear, and improved surface quality. Moreover, CFD aids in predicting the occurrence of undesirable phenomena like thermal damage, chip recutting, and vibration, enabling the design and implementation of effective strategies to mitigate these issues. Overall, the advantages of using CFD in metal cutting analysis are extensive, enabling better process understanding, enhanced performance, and cost savings.

This mind map was published on 30 December 2023 and has been viewed 89 times.