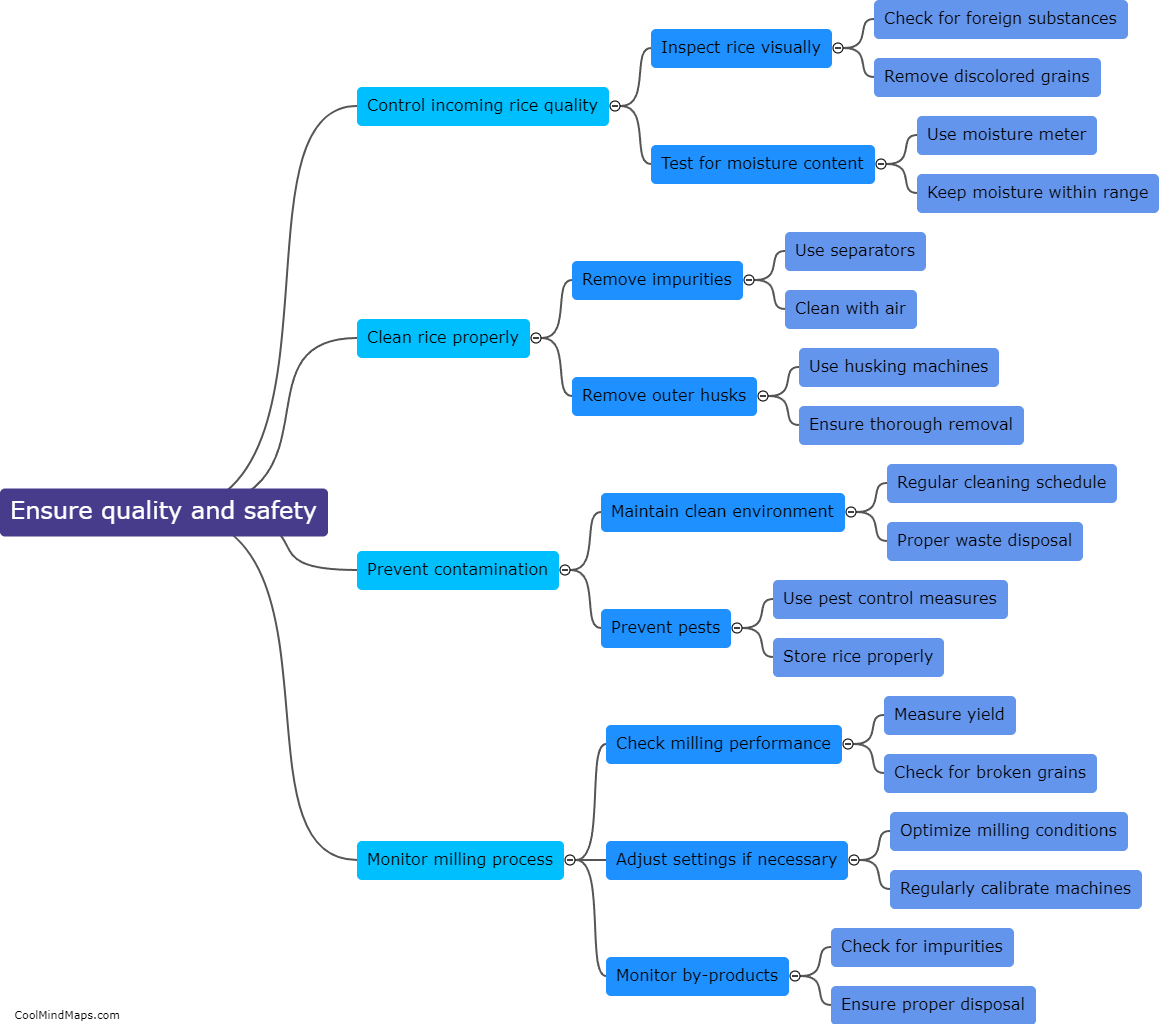

How to ensure the quality and safety of rice in the milling process?

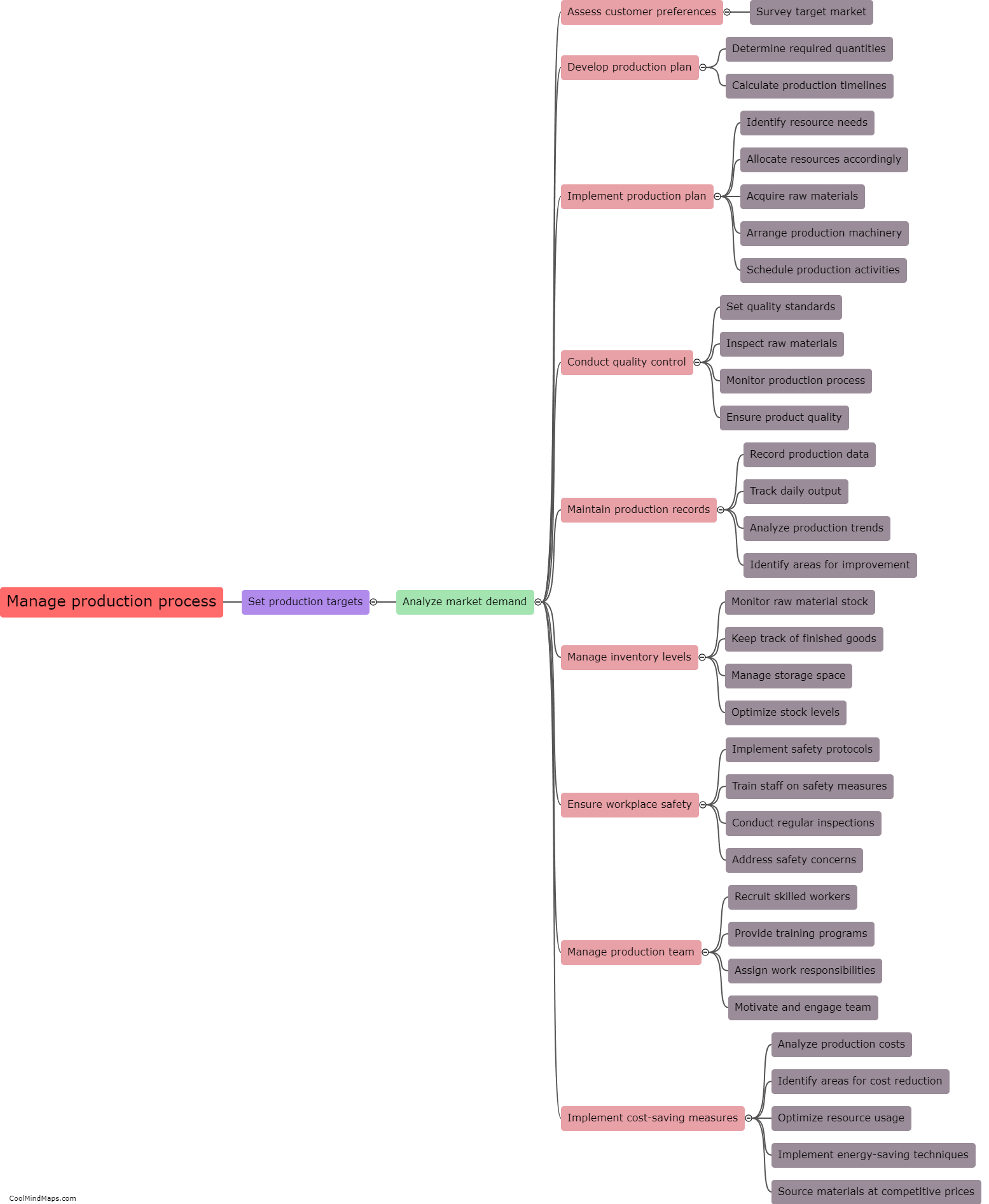

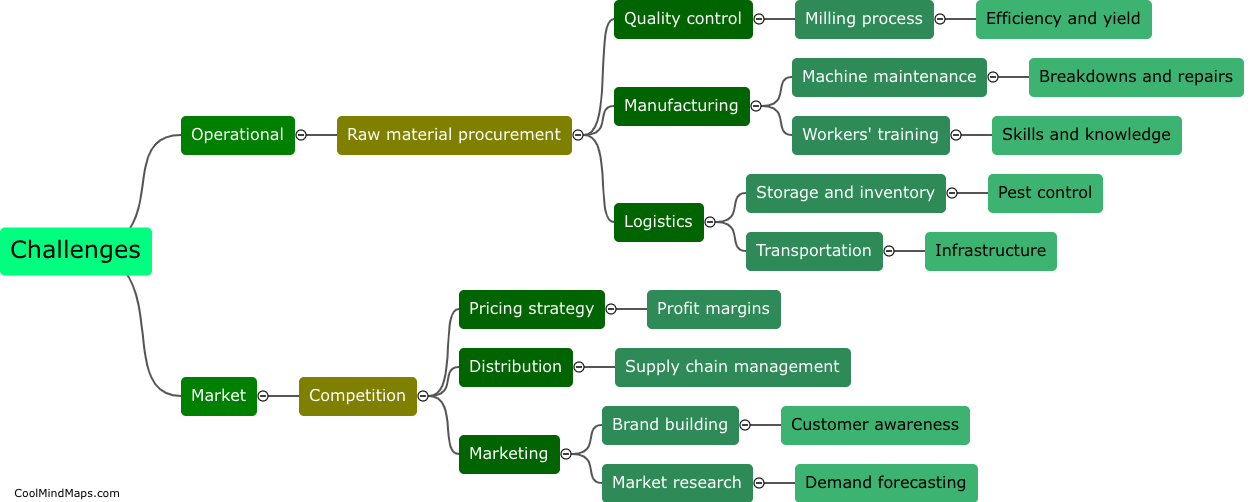

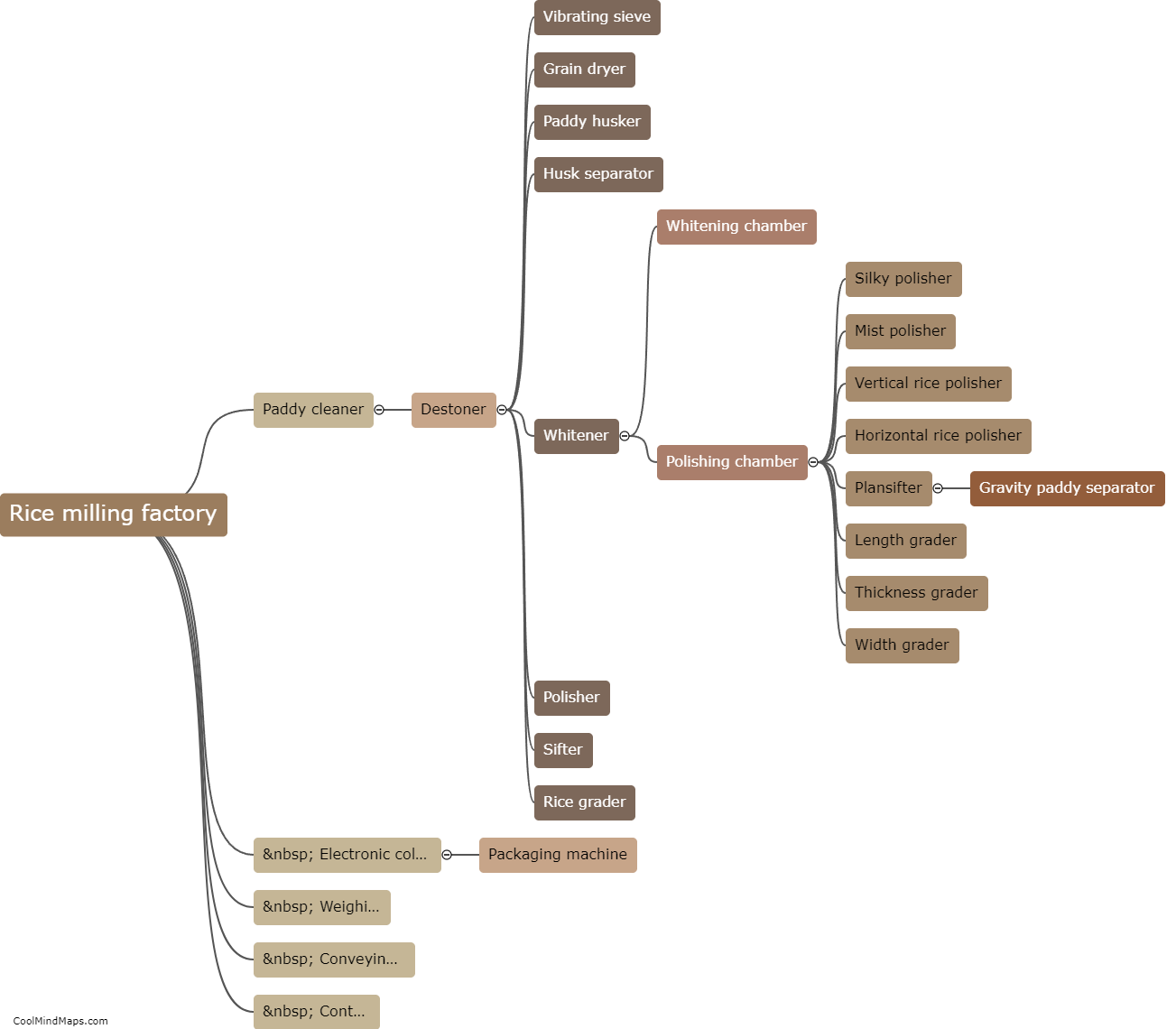

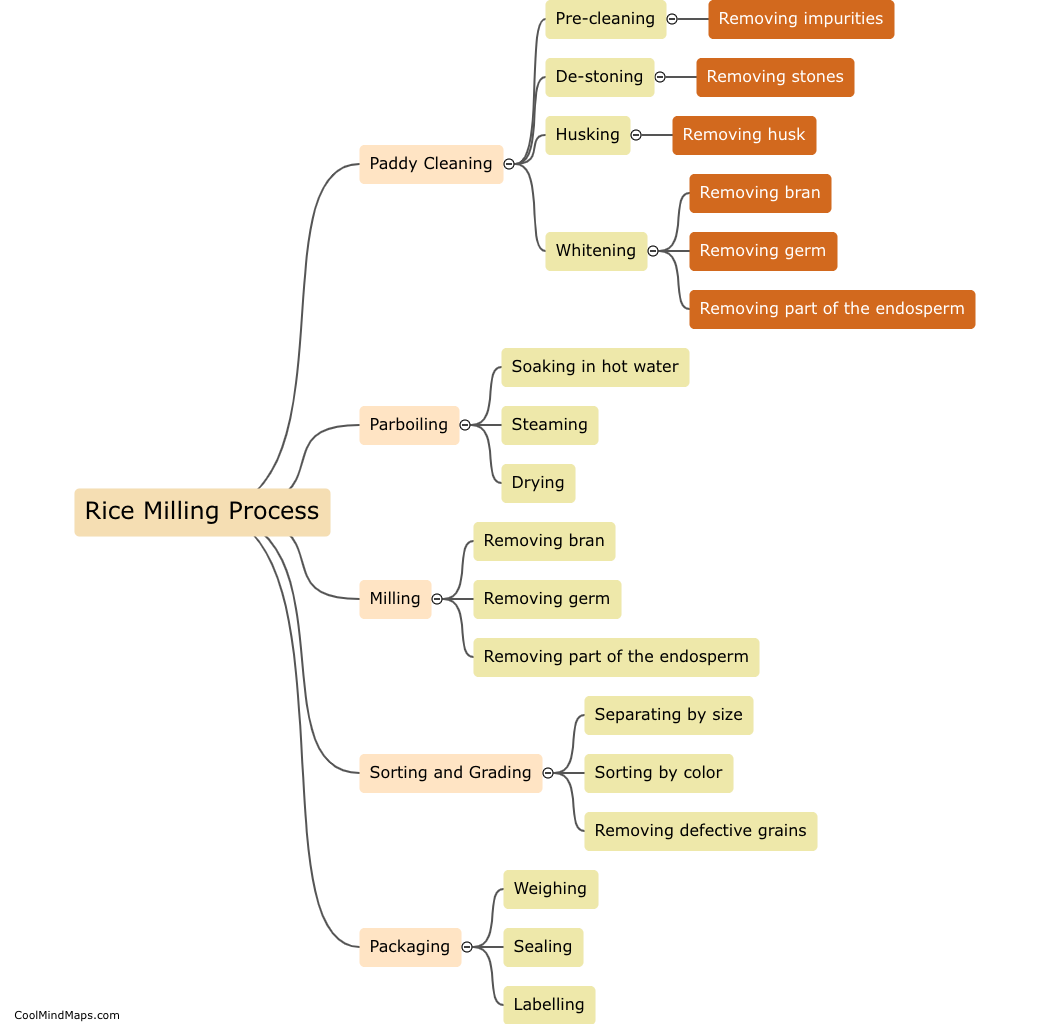

Ensuring the quality and safety of rice during the milling process is of utmost importance to deliver a product that is free from any contaminants and maintains its nutritional value. Firstly, it is crucial to carefully select the raw rice grains by considering factors such as moisture content, appearance, and mold presence. Proper cleaning of rice using advanced machinery should be conducted to remove impurities and foreign materials. Milling machines should be regularly inspected and maintained to ensure the integrity of the process, preventing any contamination. Conscious control of temperature during the milling process is essential to preserve the nutritional components of the rice. Furthermore, rigorous testing for factors like broken grains, foreign particles, and mycotoxins should be done at various stages to uphold the quality and safety standards. Continuous monitoring and adherence to proper hygiene and safety practices throughout the milling process are crucial to deliver high-quality and safe rice to consumers.

This mind map was published on 2 August 2023 and has been viewed 117 times.