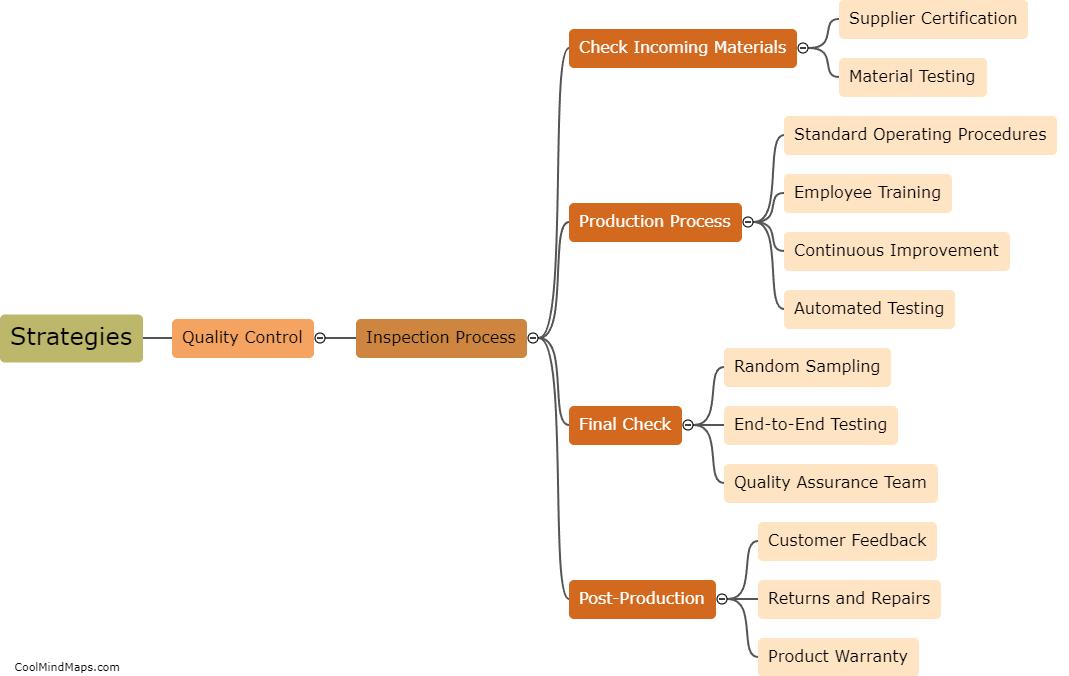

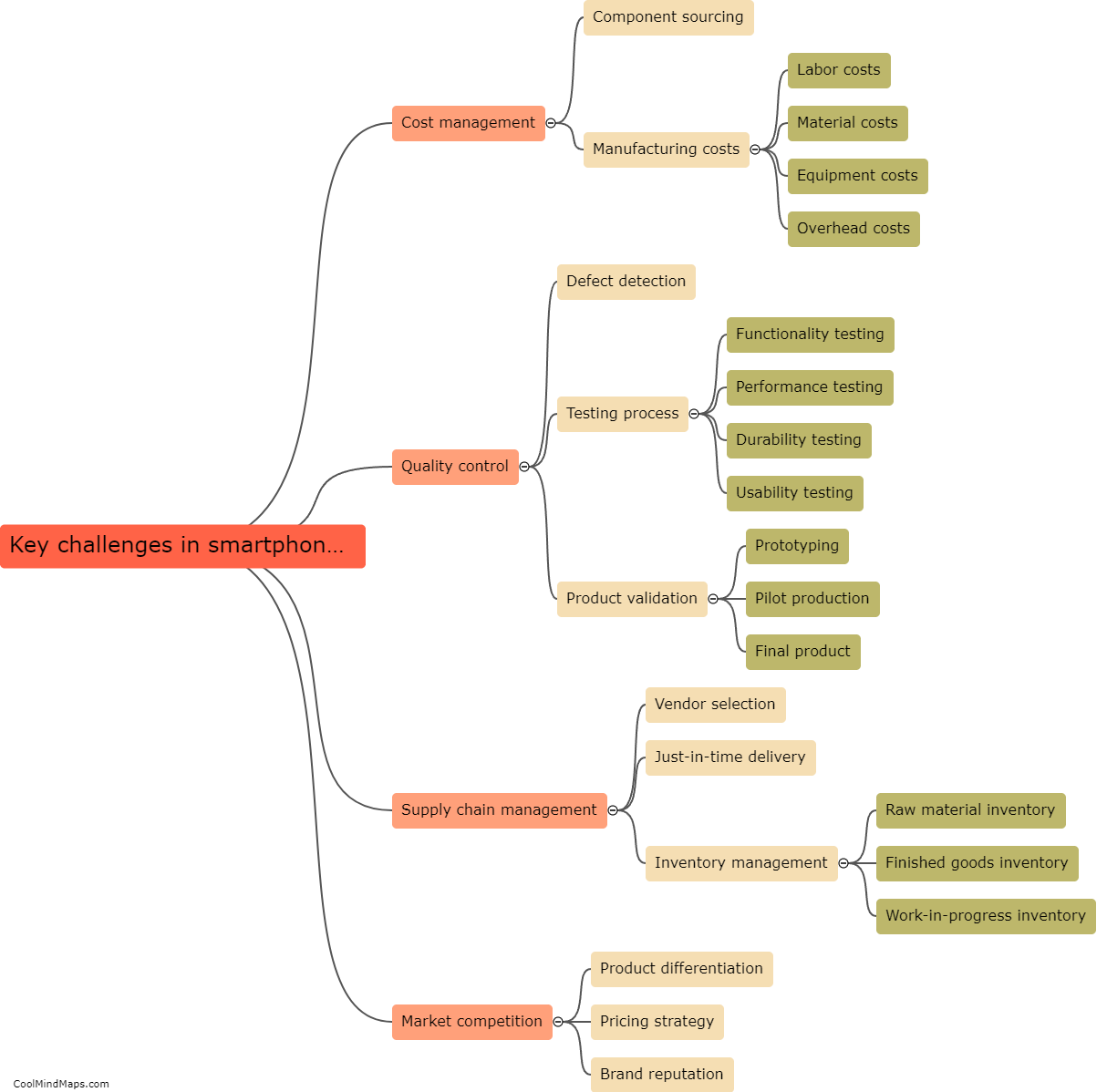

What processes can improve smartphone quality during manufacturing?

Manufacturing processes play a crucial role in enhancing smartphone quality, ensuring that the final product meets the high standards expected by consumers. One such process is strict control and management of the supply chain. By seeking reputable suppliers for components and implementing quality control measures across the entire production cycle, manufacturers can minimize the risk of defective parts or substandard materials, thus improving overall smartphone quality. Additionally, rigorous testing procedures at various stages of production can detect any potential issues early on, allowing for timely corrective actions. This includes comprehensive quality assurance checks, performance assessments, and stress testing to guarantee the durability, performance, and reliability of the smartphones. Furthermore, continuous employee training programs and a culture of quality consciousness enable workers to understand and meet the required quality standards, leading to improved craftsmanship and attention to detail. By implementing these processes, manufacturers can consistently deliver smartphones of superior quality to the market.

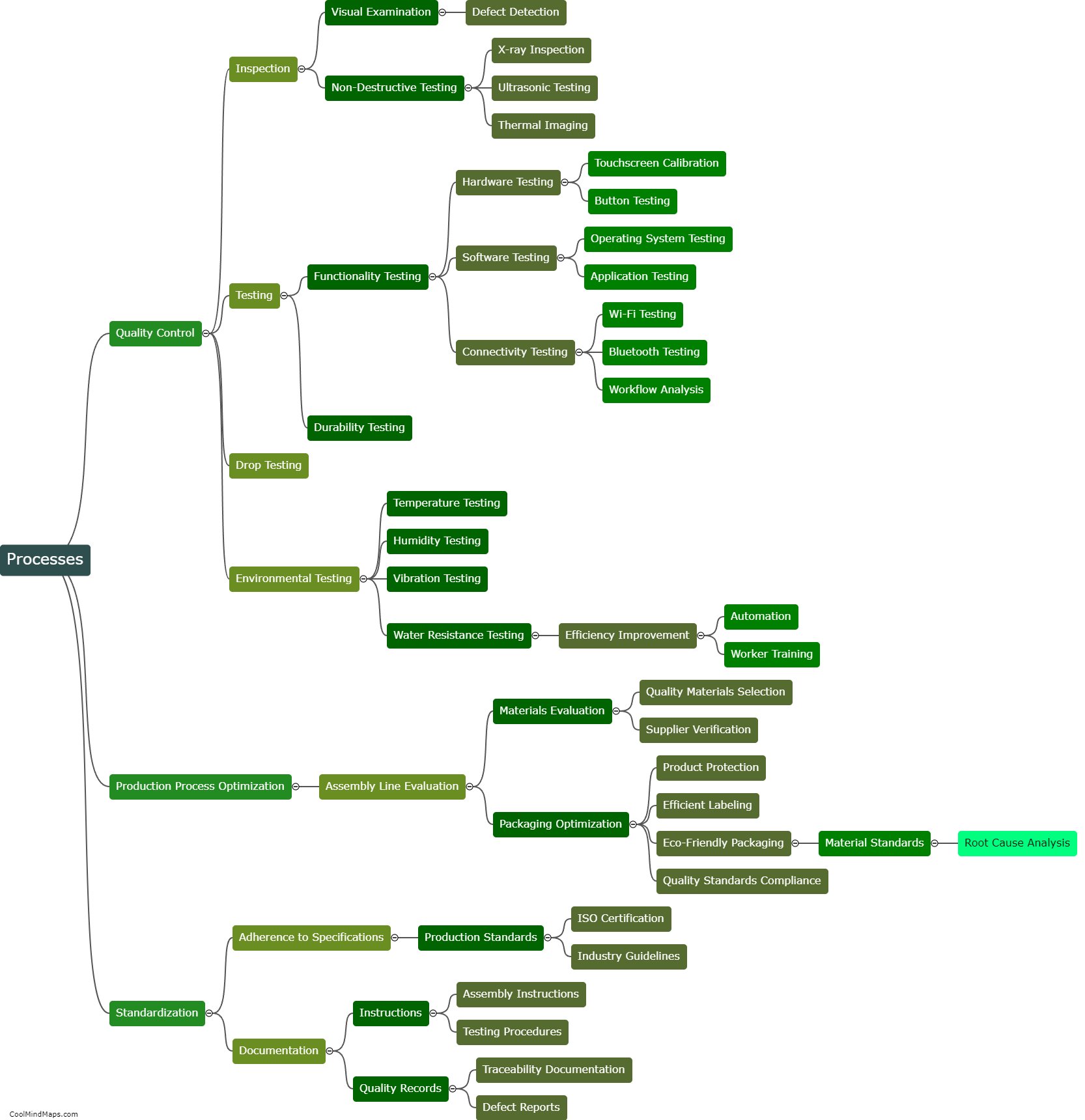

This mind map was published on 10 November 2023 and has been viewed 89 times.