How are bio implants designed and manufactured?

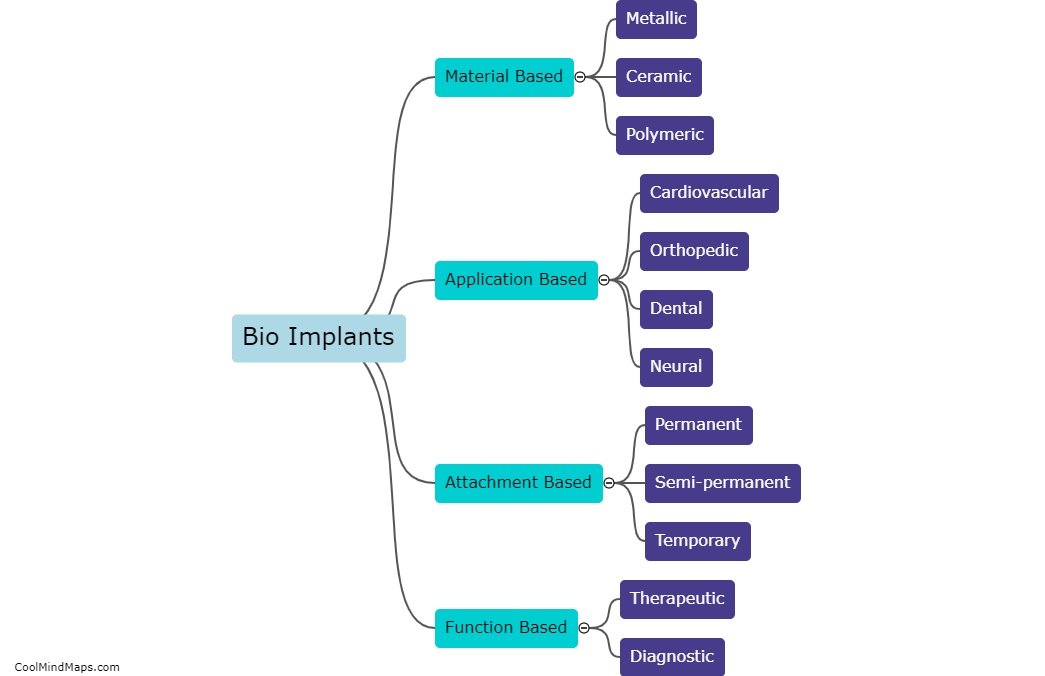

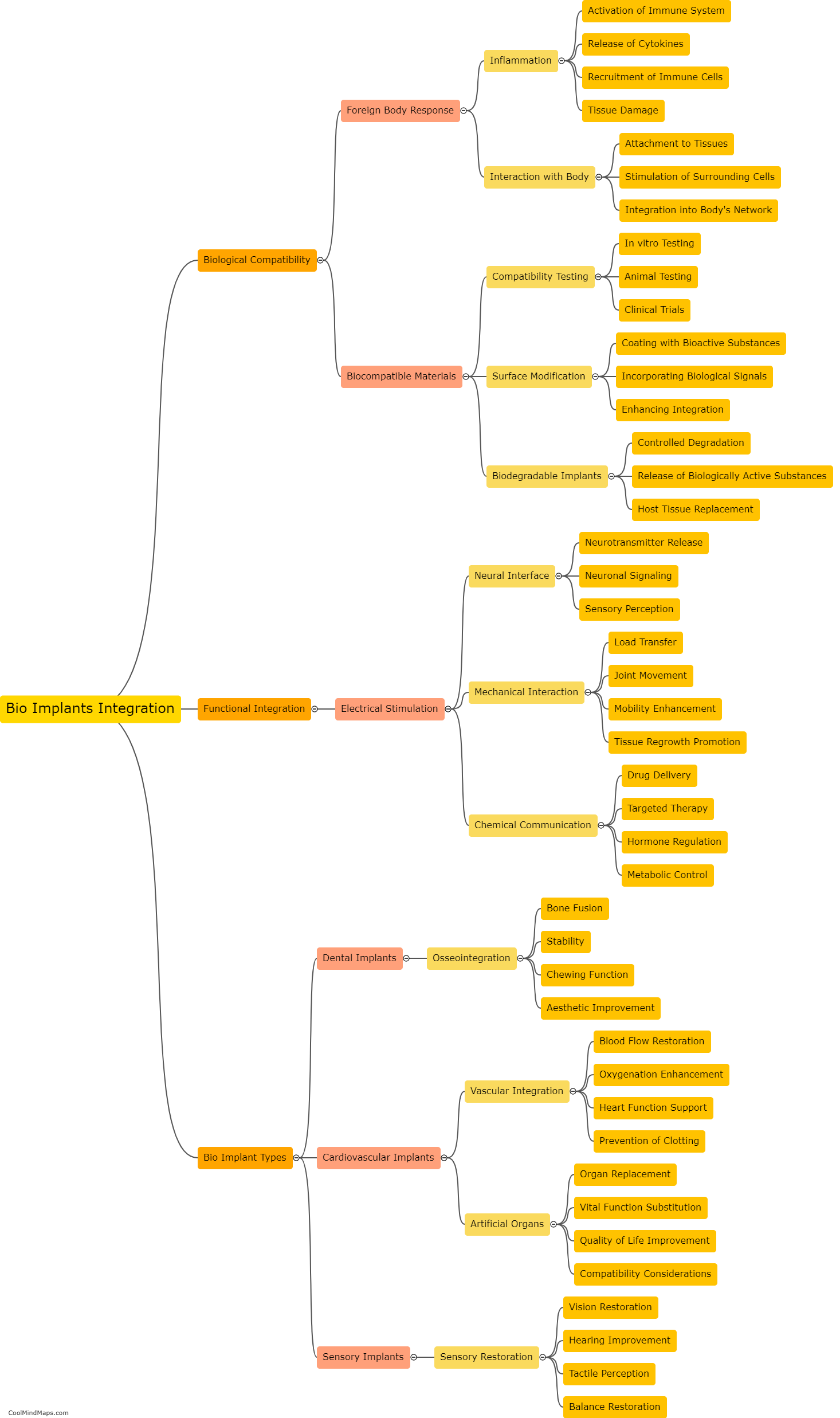

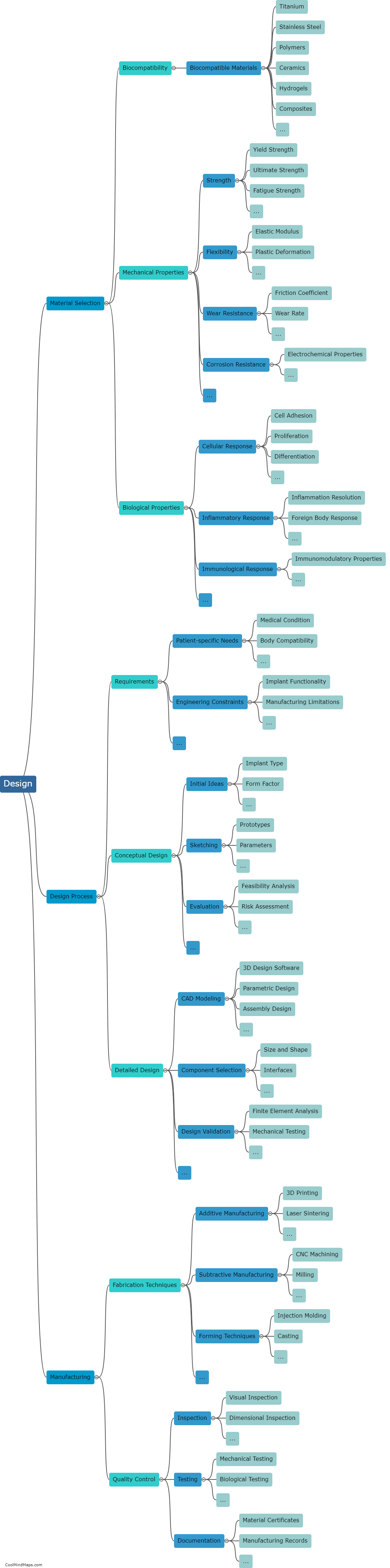

Bio implants are designed and manufactured through a meticulous process that involves a combination of medical knowledge, engineering expertise, and technological advancements. The first step in the design phase is typically a thorough analysis of the patient's anatomy and specific medical condition. This helps in customizing the implant to fit the patient's unique requirements. Computer-aided design (CAD) software is then used to create a detailed 3D model of the implant, its dimensions, and specific features. Once the design is finalized, it is sent to a specialized manufacturing facility equipped with cutting-edge machinery capable of producing intricate implant structures. Advanced materials, such as biocompatible metals or ceramics, are used to manufacture the implant. The manufacturing process may involve additive manufacturing techniques like 3D printing or subtractive methods like milling or grinding. Quality control checks ensure the implant's integrity before it is sterilized and ready for implantation, contributing to the restoration of function and well-being of patients.

This mind map was published on 19 December 2023 and has been viewed 86 times.