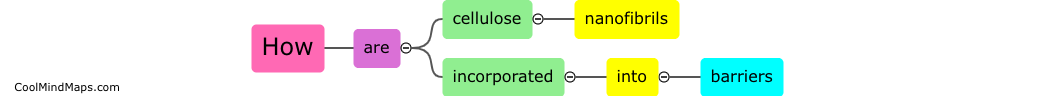

What is the process of incorporating cellulose nanofibrils into paper packaging?

The process of incorporating cellulose nanofibrils into paper packaging involves several key steps. Firstly, cellulose nanofibrils, which are derived from plant-based sources such as wood pulp, are produced through mechanical or chemical processing methods that break down cellulose fibers into ultra-small fibrils. These nanofibrils offer enhanced strength, flexibility, and barrier properties compared to traditional cellulose fibers. In the next step, the nanofibrils are mixed with water or other solvents to form a suspension or gel-like substance. This suspension is then added to the paper pulp during the papermaking process. The nanofibrils disperse evenly within the pulp, becoming integrated into the paper matrix. Finally, the paper is dried and finished to obtain the desired properties of cellulose nanofibril-incorporated paper packaging, which can include increased strength, improved moisture resistance, and enhanced biodegradability. This incorporation process holds significant potential for sustainable and eco-friendly packaging solutions.

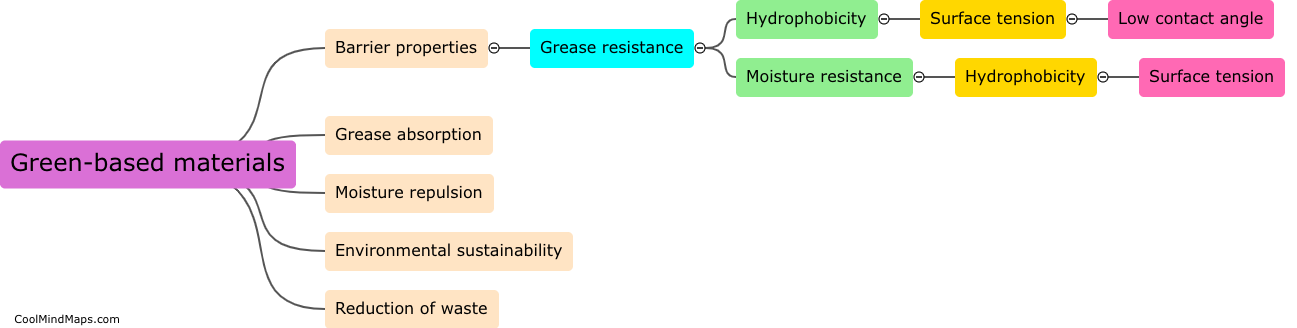

This mind map was published on 30 November 2023 and has been viewed 95 times.