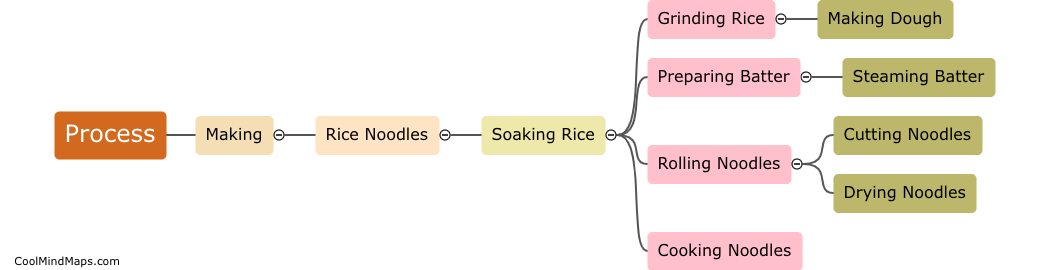

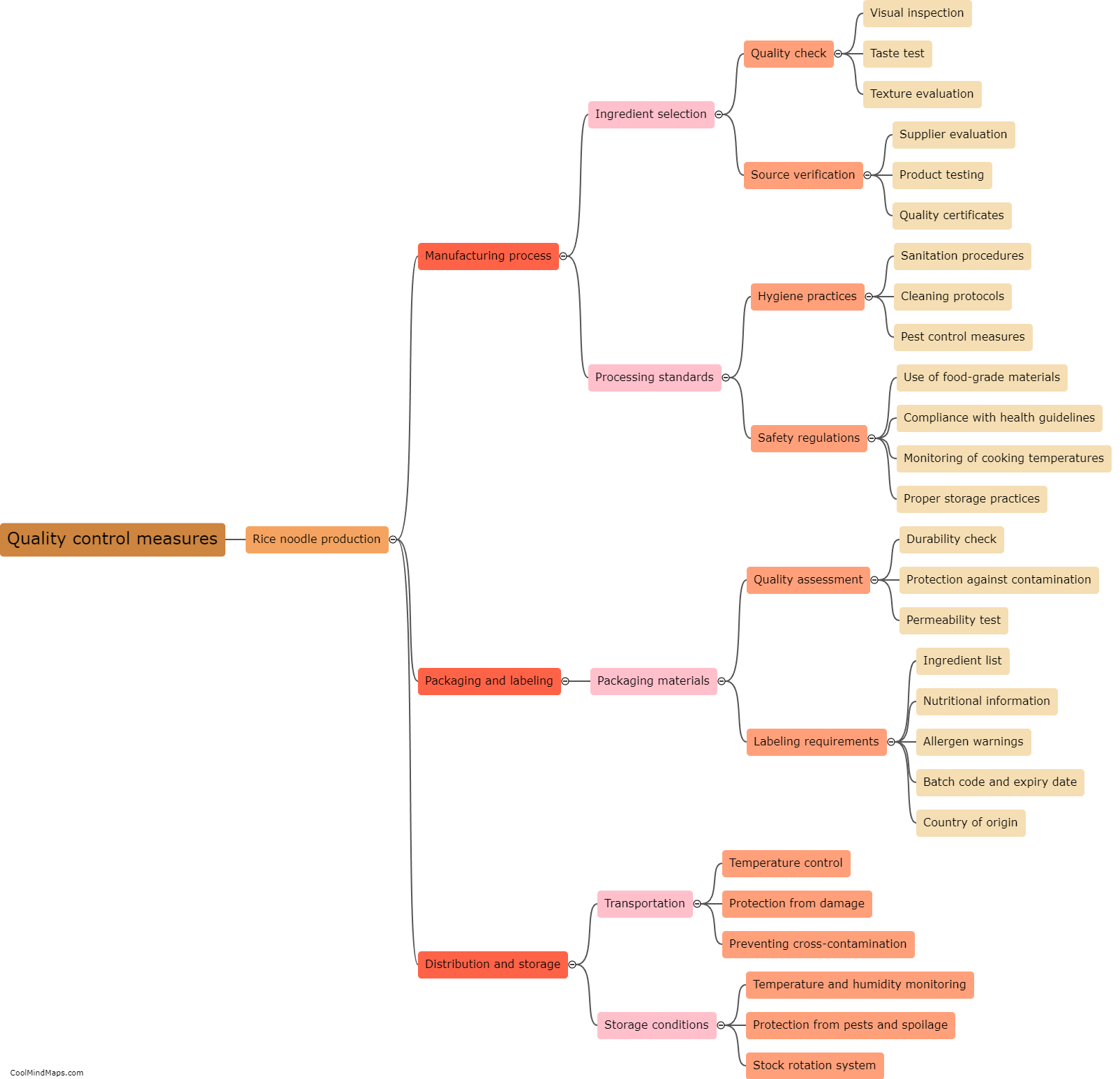

Are there any quality control measures in rice noodle production?

In the production of rice noodles, several quality control measures are implemented to ensure the manufacturing process adheres to specific standards and produces noodles of consistent quality. These measures typically include rigorous inspection of the raw materials, such as the rice and water used in the noodle-making process, to ensure they meet the required quality standards. Additionally, quality control measures are implemented at each stage of production, such as monitoring the milling process, rolling thickness, and drying methods, to ensure that the noodles are uniform in texture, taste, and appearance. Regular testing and sampling are conducted throughout the production process to identify any potential deviations from the desired quality and to make necessary adjustments. By implementing these quality control measures, manufacturers can provide rice noodles that meet the consumers' expectations in terms of taste, texture, and overall quality.

This mind map was published on 31 July 2023 and has been viewed 102 times.