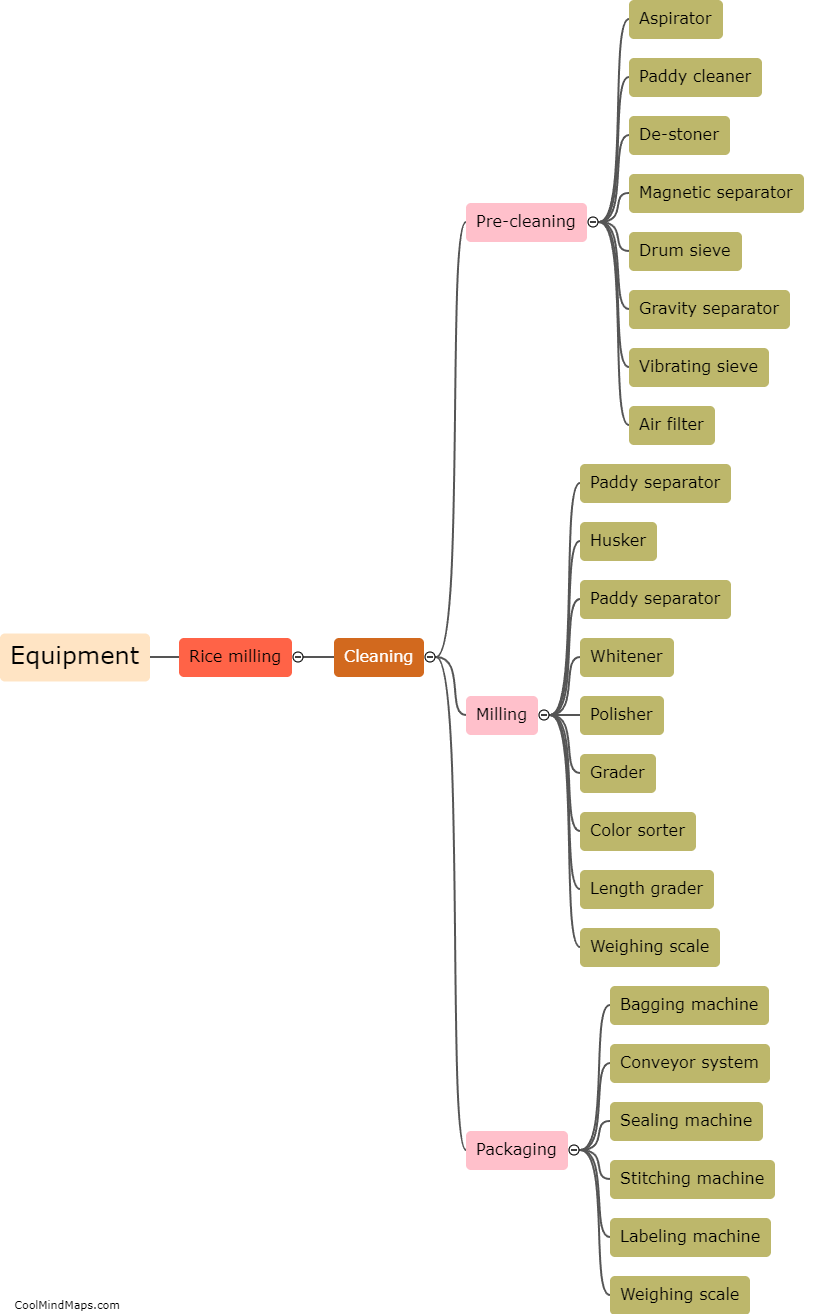

What equipment is required for a rice milling factory?

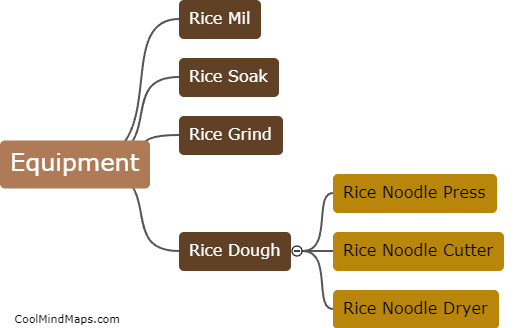

A rice milling factory requires several pieces of equipment to efficiently process and produce rice. The essential equipment includes a paddy cleaning machine, which removes impurities and unwanted materials from the raw rice; a paddy husker, which removes the husk or outer layer of the rice grain; a paddy separator, which separates the paddy from the brown rice; and a rice whitener, which removes the bran layer from the rice grain. Additionally, a rice grading machine is needed to sort the rice into different sizes and qualities based on market demands. Other auxiliary equipment that may be required includes a rice polisher, color sorter for removing impurities based on color, and packaging machines for proper packaging and storage of the processed rice. All of these equipment combined provide the necessary mechanisms for a rice milling factory to efficiently and effectively produce high-quality rice.

This mind map was published on 31 July 2023 and has been viewed 133 times.