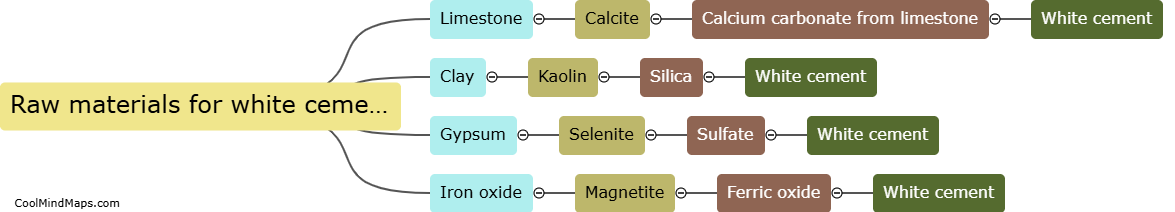

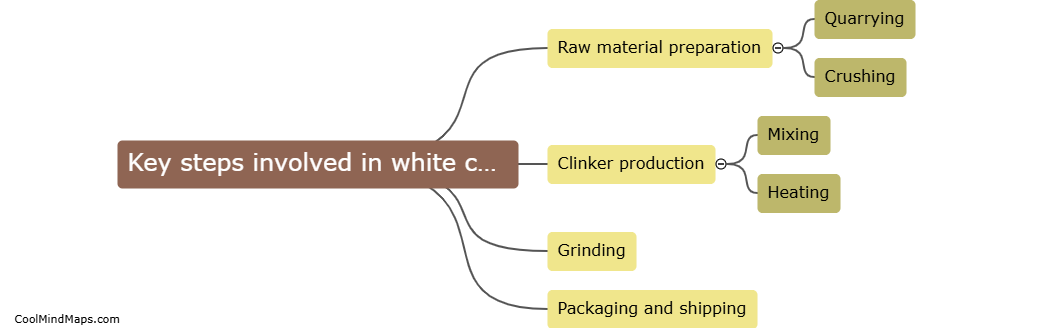

Key steps involved in white cement production

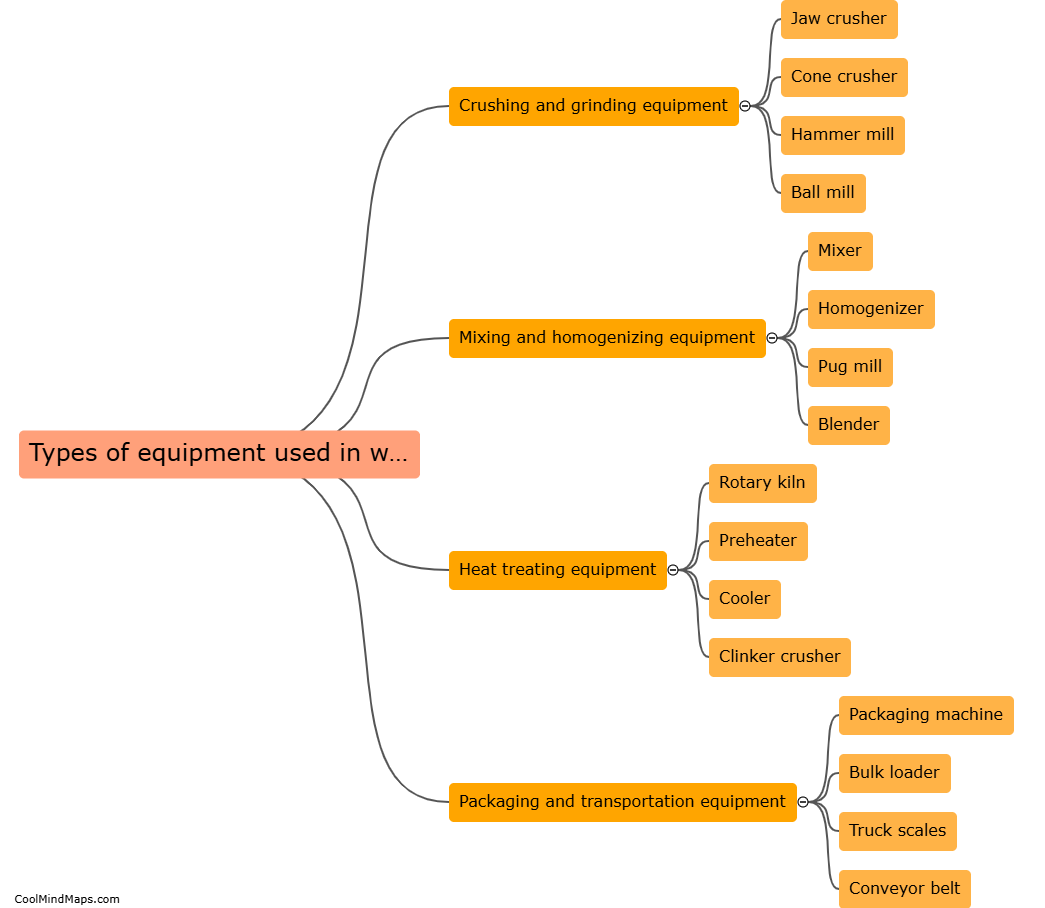

White cement production involves several key steps to ensure high-quality and consistent products. Firstly, raw materials like limestone and clay are carefully selected and crushed into a fine powder. Next, the raw materials are mixed in specific proportions and heated in a kiln at high temperatures to form clinker. The clinker is then finely ground with gypsum to produce white cement powder. Finally, the powder is packed into bags and stored for distribution. Quality control measures are implemented throughout the production process to ensure the final product meets industry standards and customer expectations.

This mind map was published on 12 December 2024 and has been viewed 18 times.