What are the potential challenges of integrating IoT in rice milling factories?

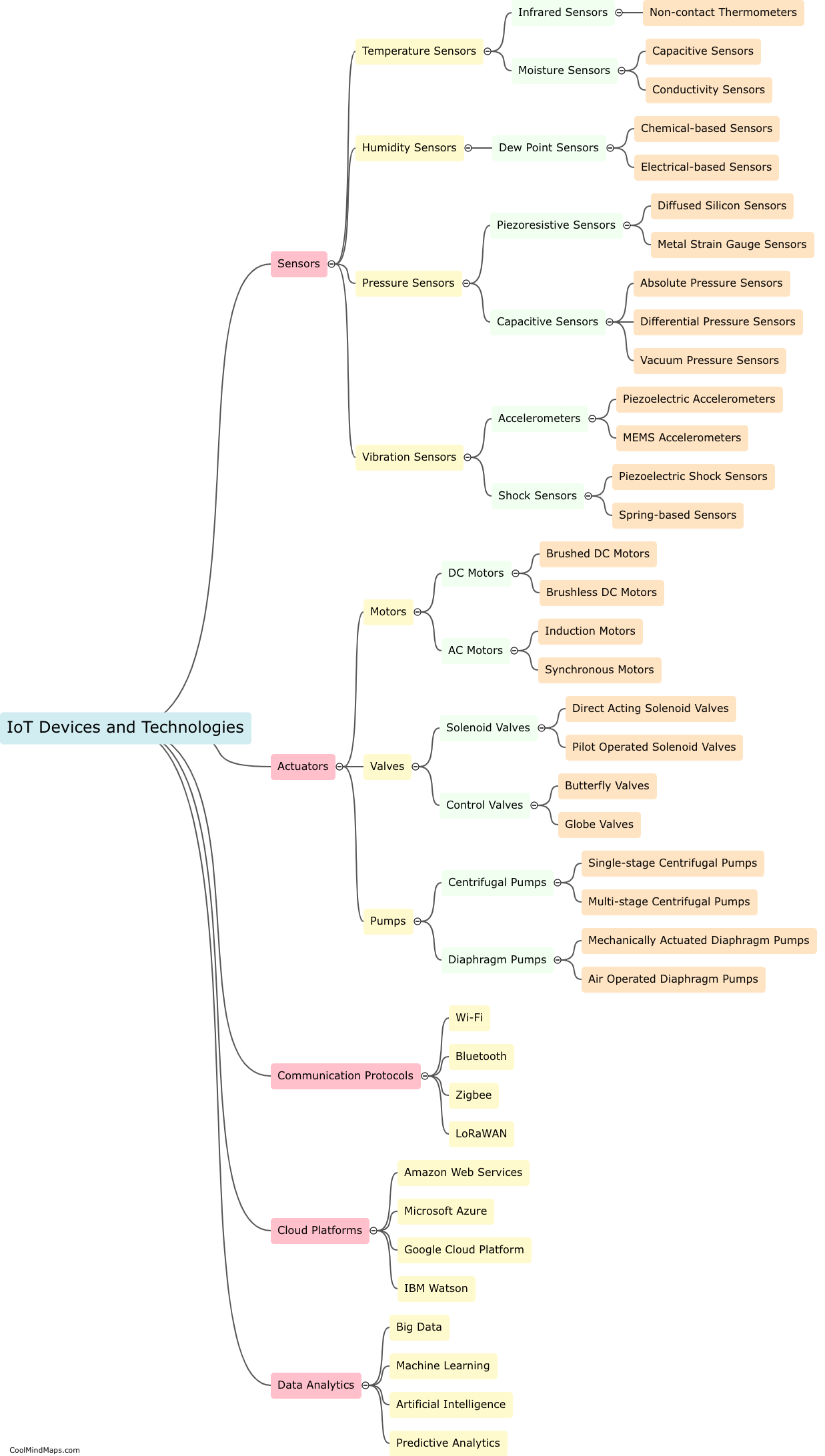

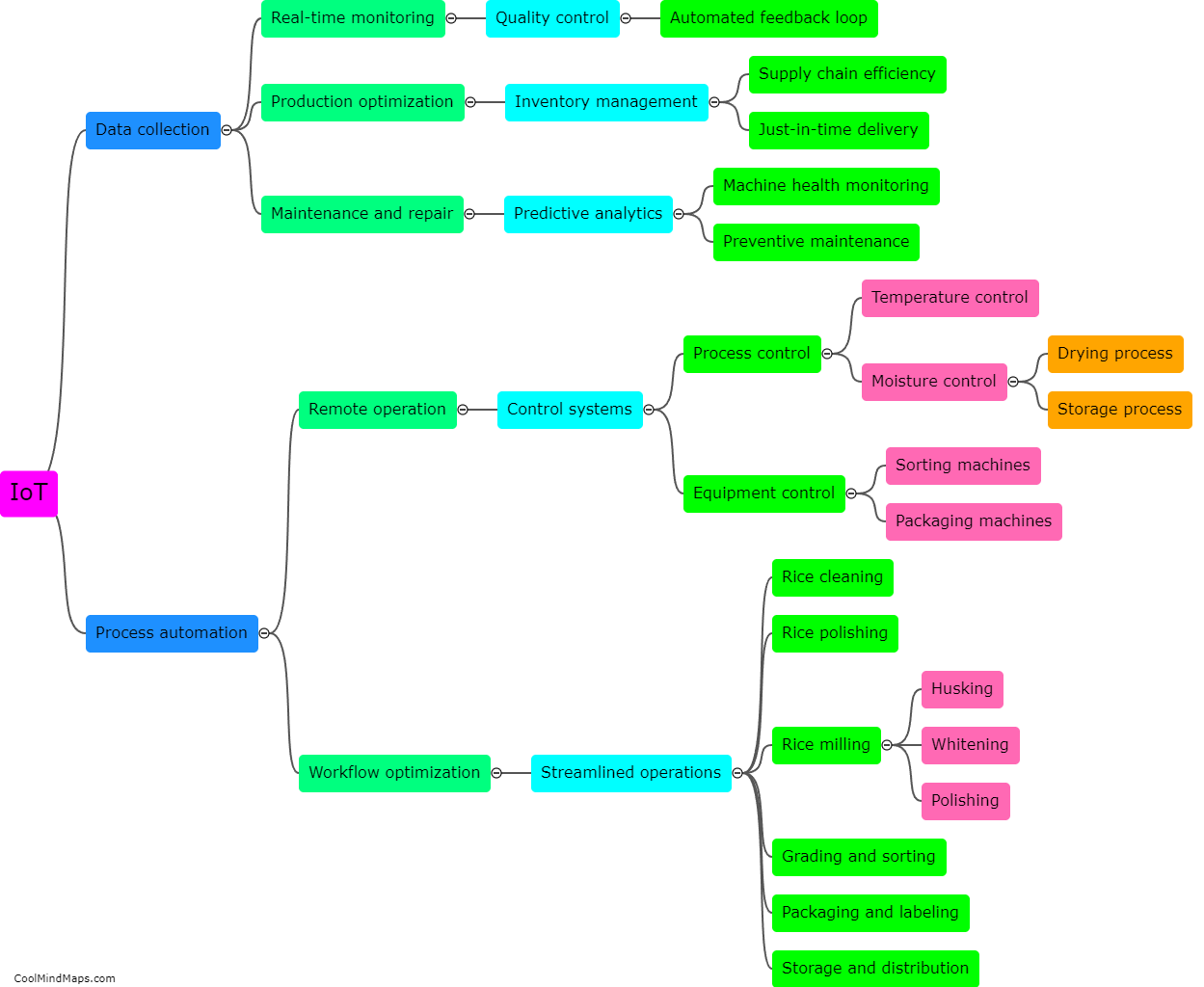

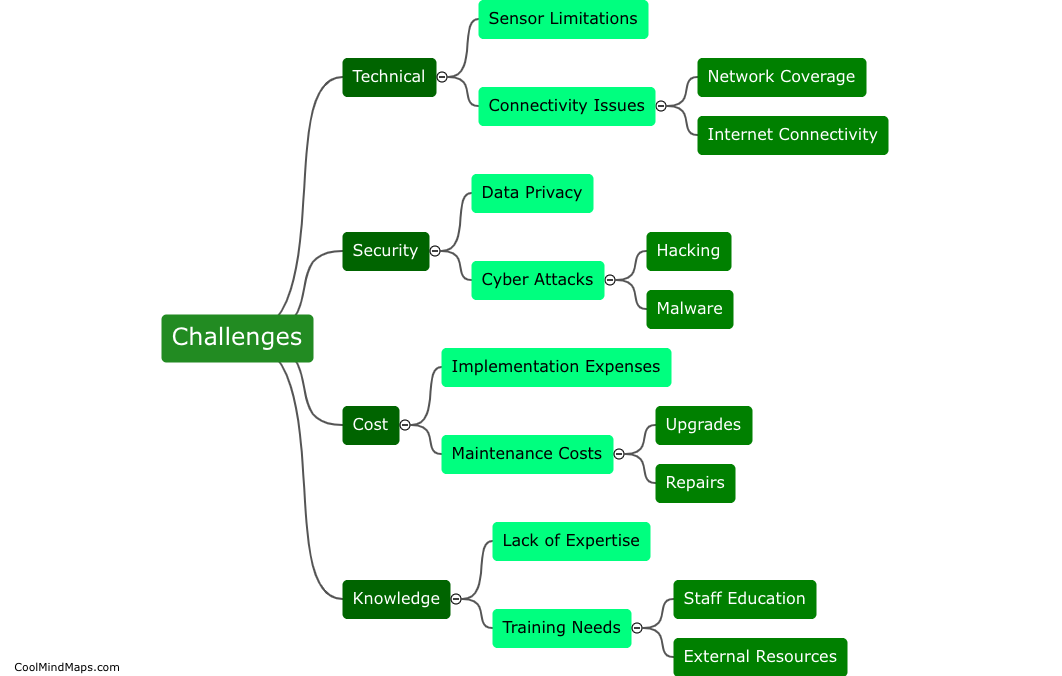

Integrating IoT (Internet of Things) in rice milling factories comes with potential challenges that need to be addressed for successful implementation. Firstly, ensuring compatibility and connectivity among various IoT devices, sensors, and systems can be a challenge. Different manufacturers may use different communication protocols, making it difficult to establish a seamless network. Secondly, handling and managing large amounts of data generated by IoT devices can be overwhelming. Implementing robust data management systems and analytics tools is crucial to derive actionable insights. Thirdly, security and privacy concerns arise with the collection and transmission of sensitive data. Protecting against cyber-attacks and ensuring data privacy becomes essential. Additionally, the cost associated with implementing IoT systems and training staff to effectively utilize them can be a hurdle for small-scale rice milling factories. Addressing these challenges is crucial to reap the benefits of IoT integration in enhancing operational efficiency, optimizing resource utilization, and improving product quality in rice milling factories.

This mind map was published on 30 July 2023 and has been viewed 105 times.