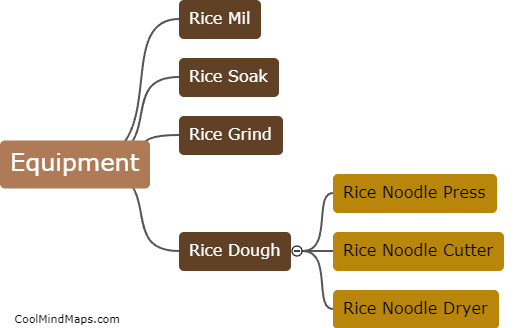

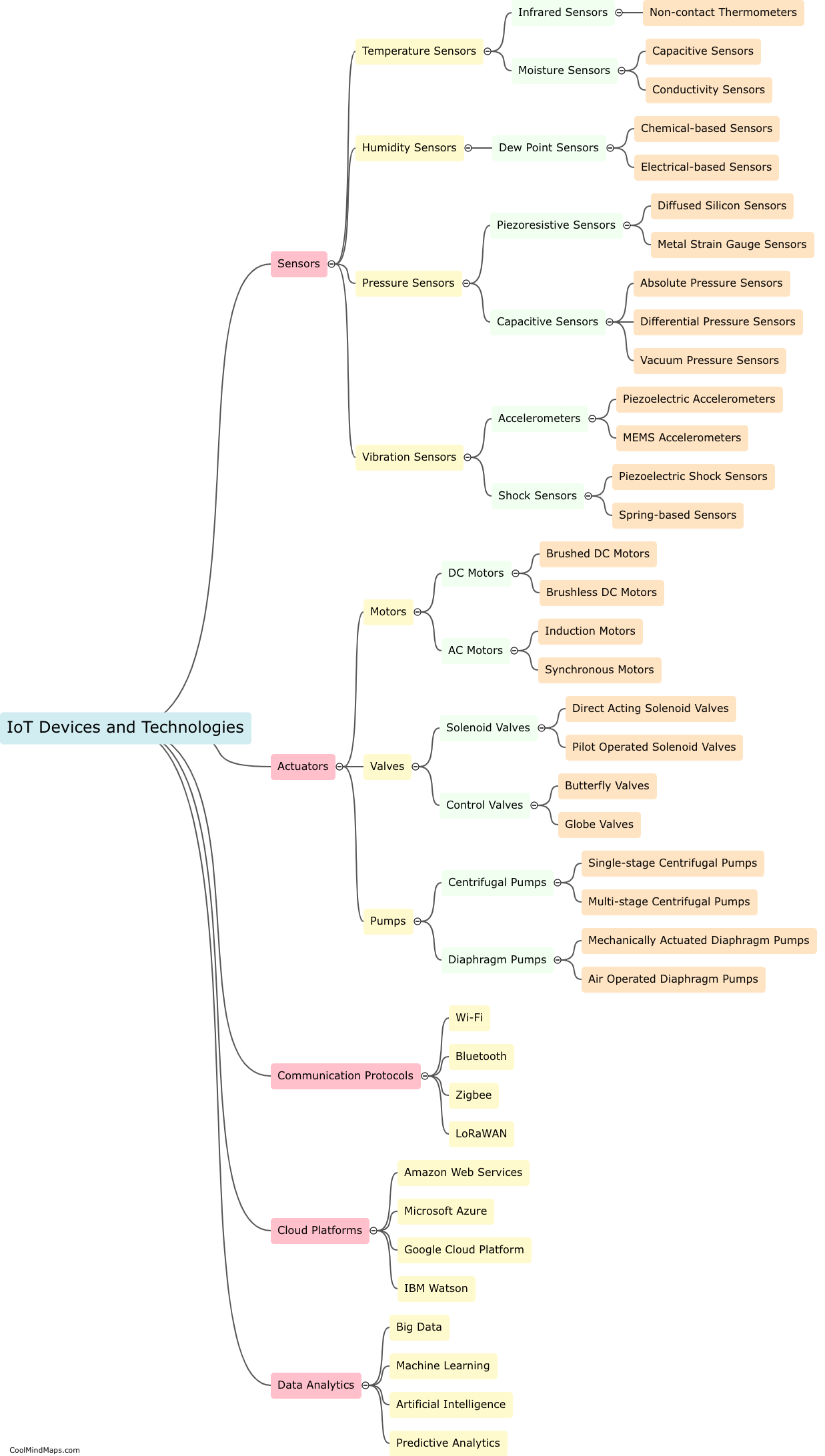

What IoT devices and technologies can be used in rice milling?

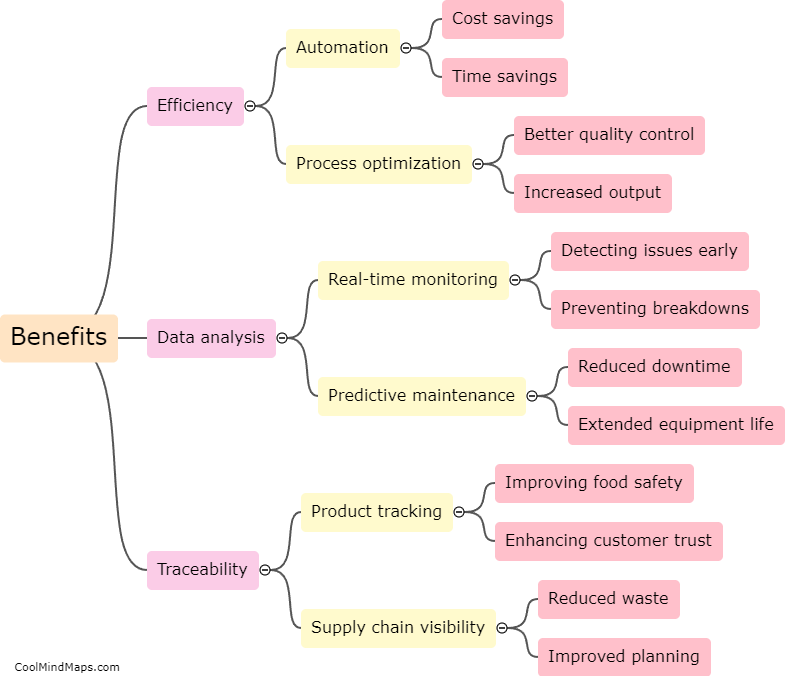

In the rice milling industry, various IoT devices and technologies can be deployed to streamline operations, enhance efficiency, and improve quality control. One such device is smart sensors, which can be installed in different parts of the rice mill to monitor key parameters like temperature, humidity, and moisture levels. By collecting and analyzing this data in real-time, mill operators can optimize the milling process, ensuring the rice grains are processed at the appropriate conditions. Additionally, IoT-enabled machines can automate various tasks, such as sorting, grading, and packaging, reducing human intervention and increasing productivity. These machines can be monitored and operated remotely, allowing for better control and responsiveness. Furthermore, data analysis and machine learning algorithms can be employed to detect any deviations from the standard milling process, preventing wastage and enhancing product quality. Overall, the integration of IoT devices and technologies in rice milling holds great potential for increasing efficiency, reducing waste, and streamlining the entire production cycle.

This mind map was published on 30 July 2023 and has been viewed 113 times.