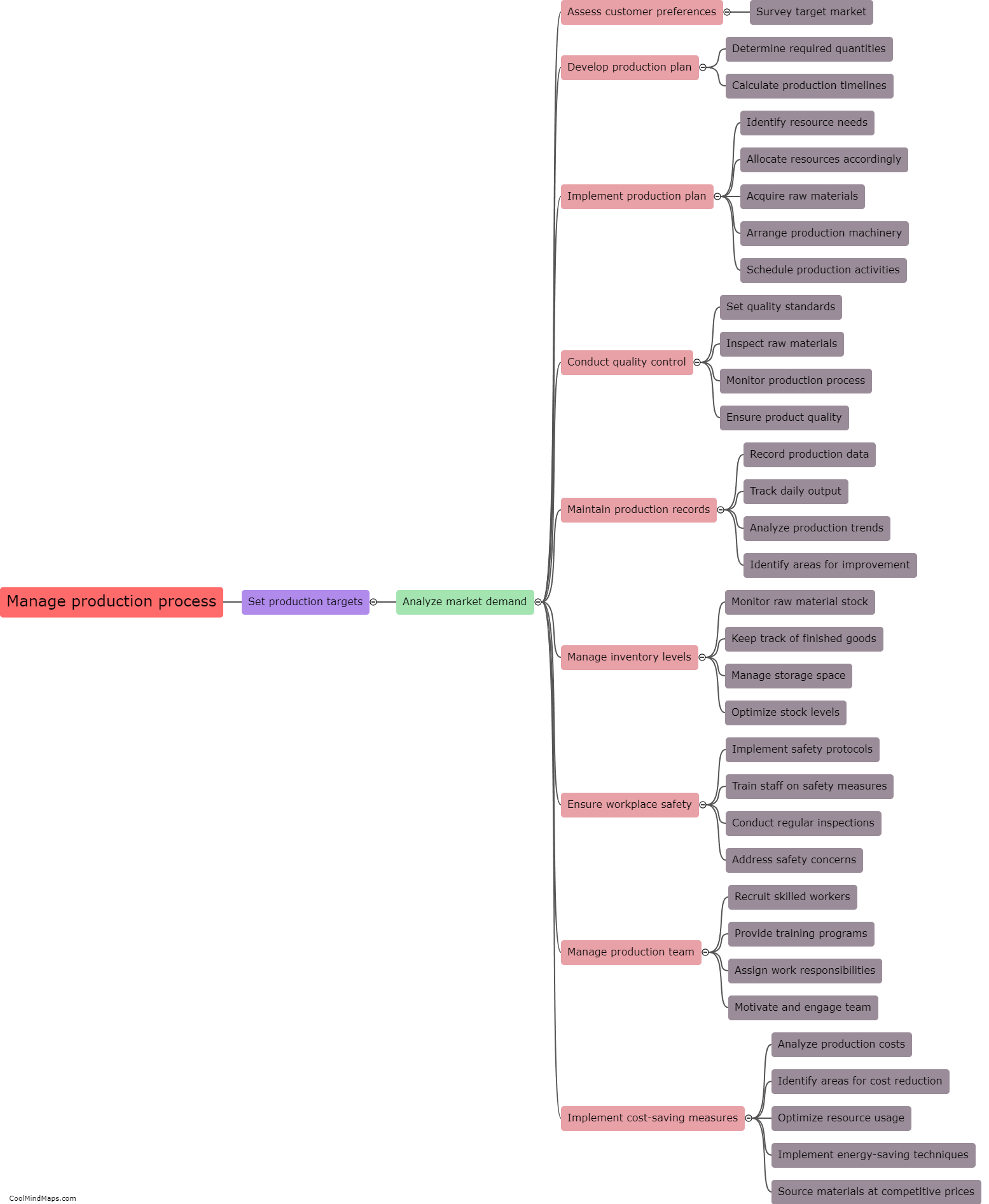

How to manage the production process in a rice milling factory?

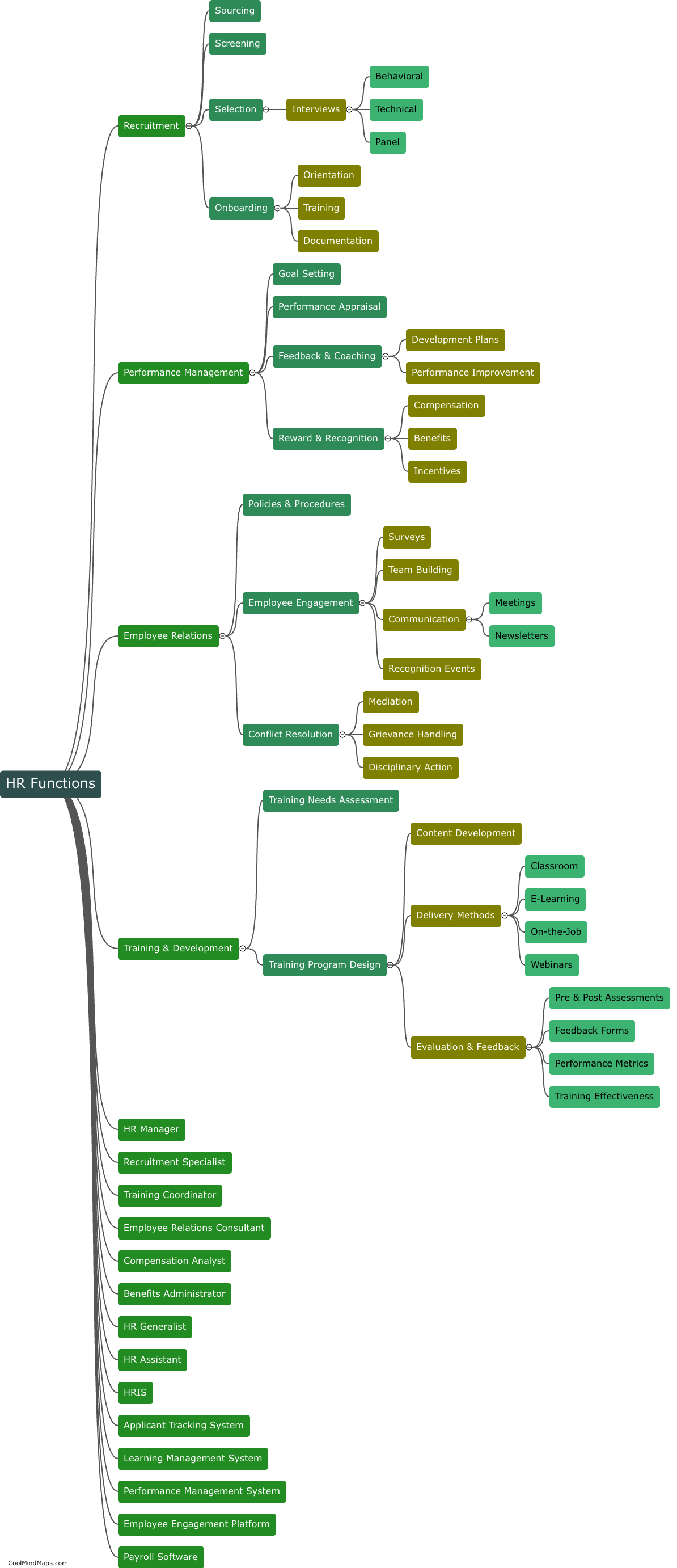

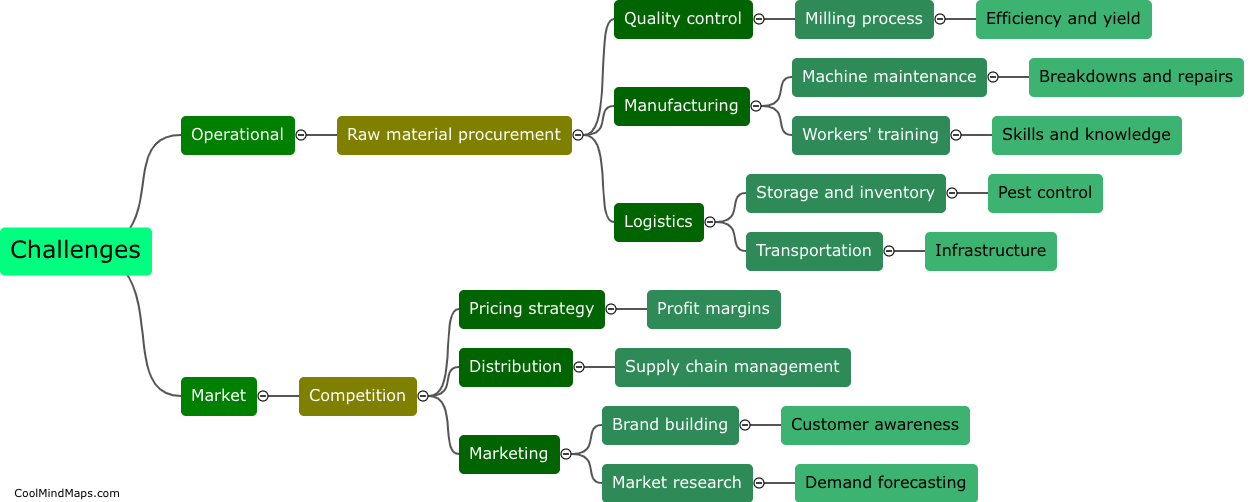

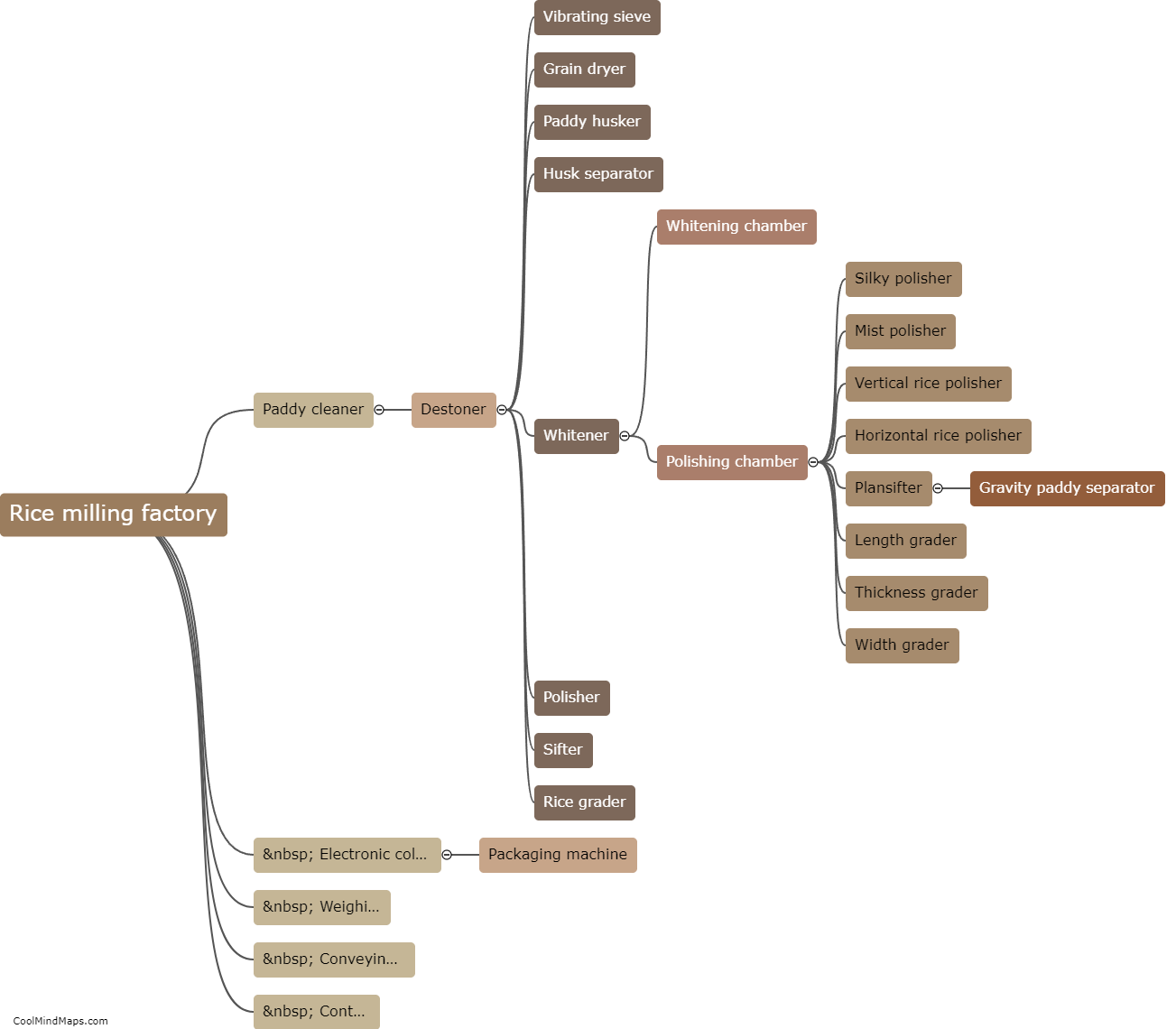

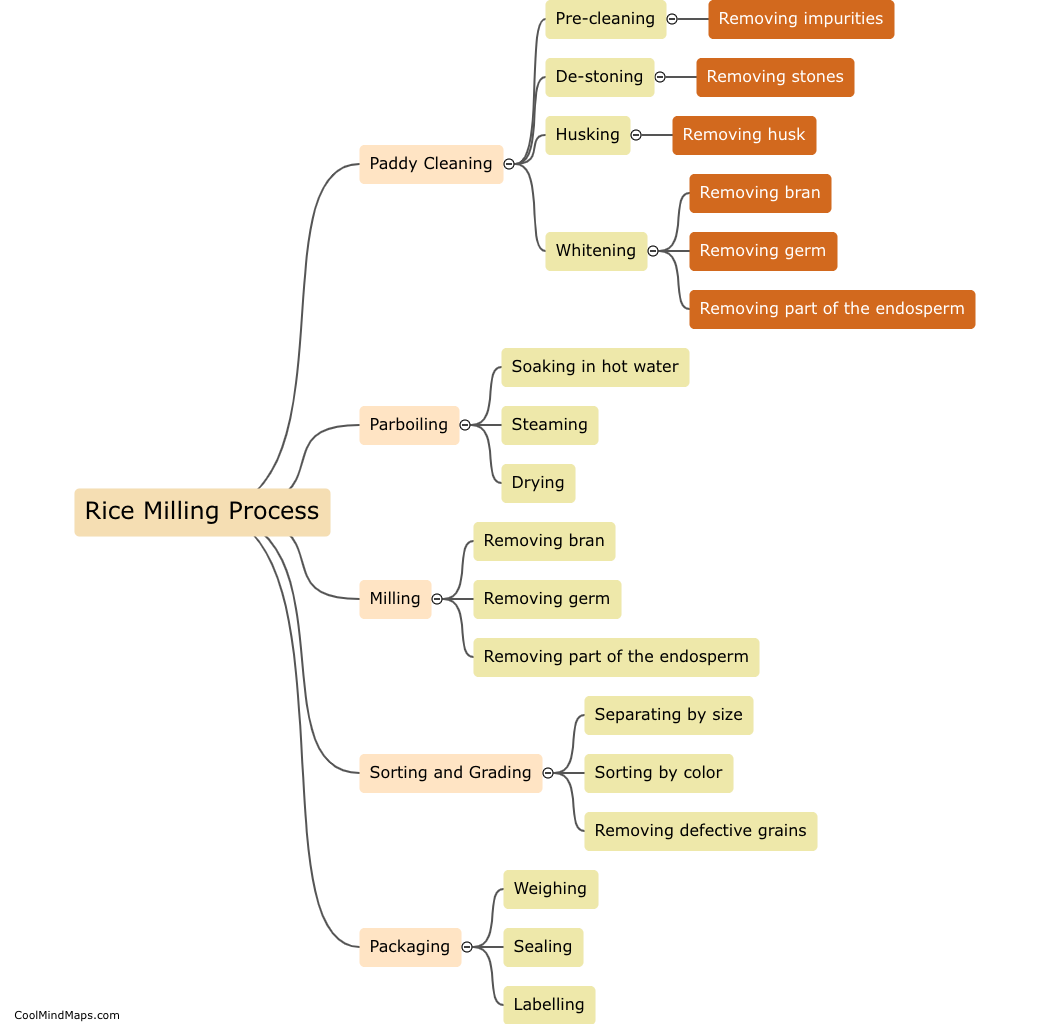

Managing the production process in a rice milling factory requires careful planning and systematic supervision to ensure smooth and efficient operations. Firstly, it is essential to determine the quantity of raw rice for processing each day. This can be achieved by analyzing market demand and ensuring an adequate supply of paddy. Secondly, the rice milling machines should be regularly maintained and calibrated to ensure optimal performance. Quality control checks must be implemented at various stages of the production process to maintain consistent rice quality. Additionally, effective inventory management is crucial to ensure proper storage and timely delivery of the final rice products. Finally, regular staff training and performance evaluations are necessary to enhance productivity and maintain a high standard of workmanship in the rice milling factory. By implementing these steps, a rice milling factory can effectively manage its production process and deliver high-quality rice products to the market.

This mind map was published on 2 August 2023 and has been viewed 102 times.