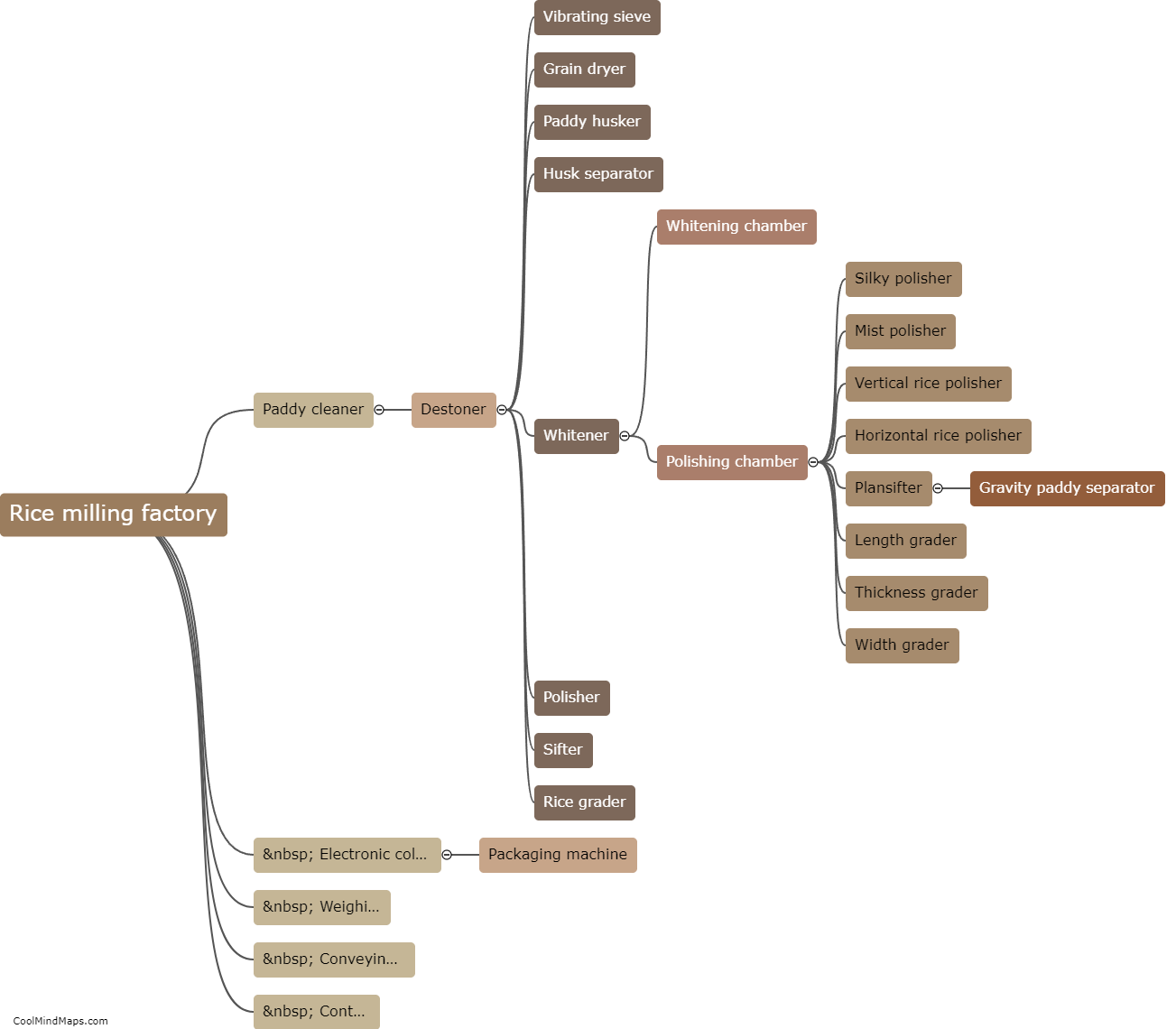

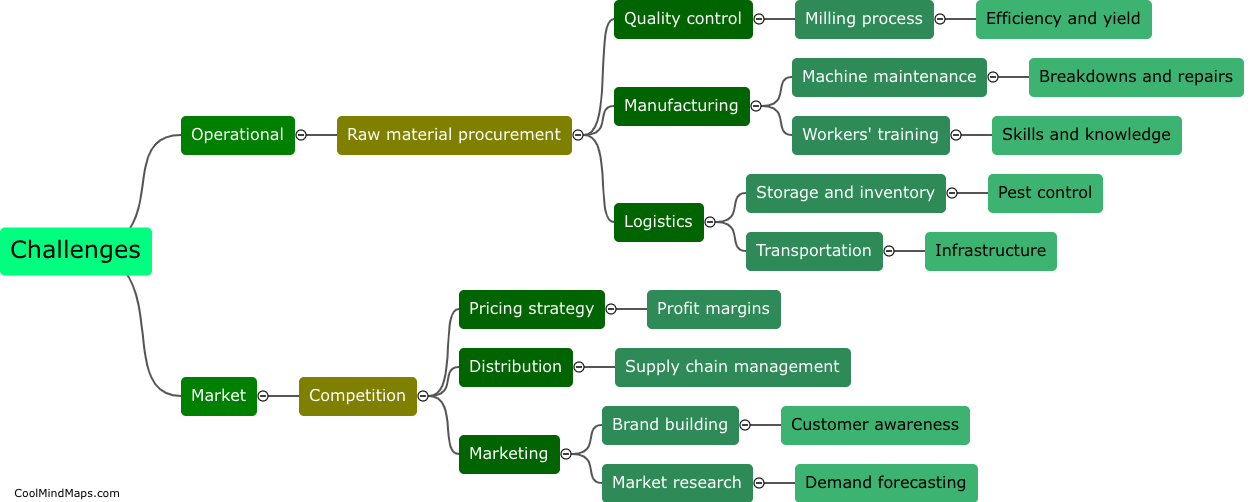

What are the potential challenges in operating a rice milling factory?

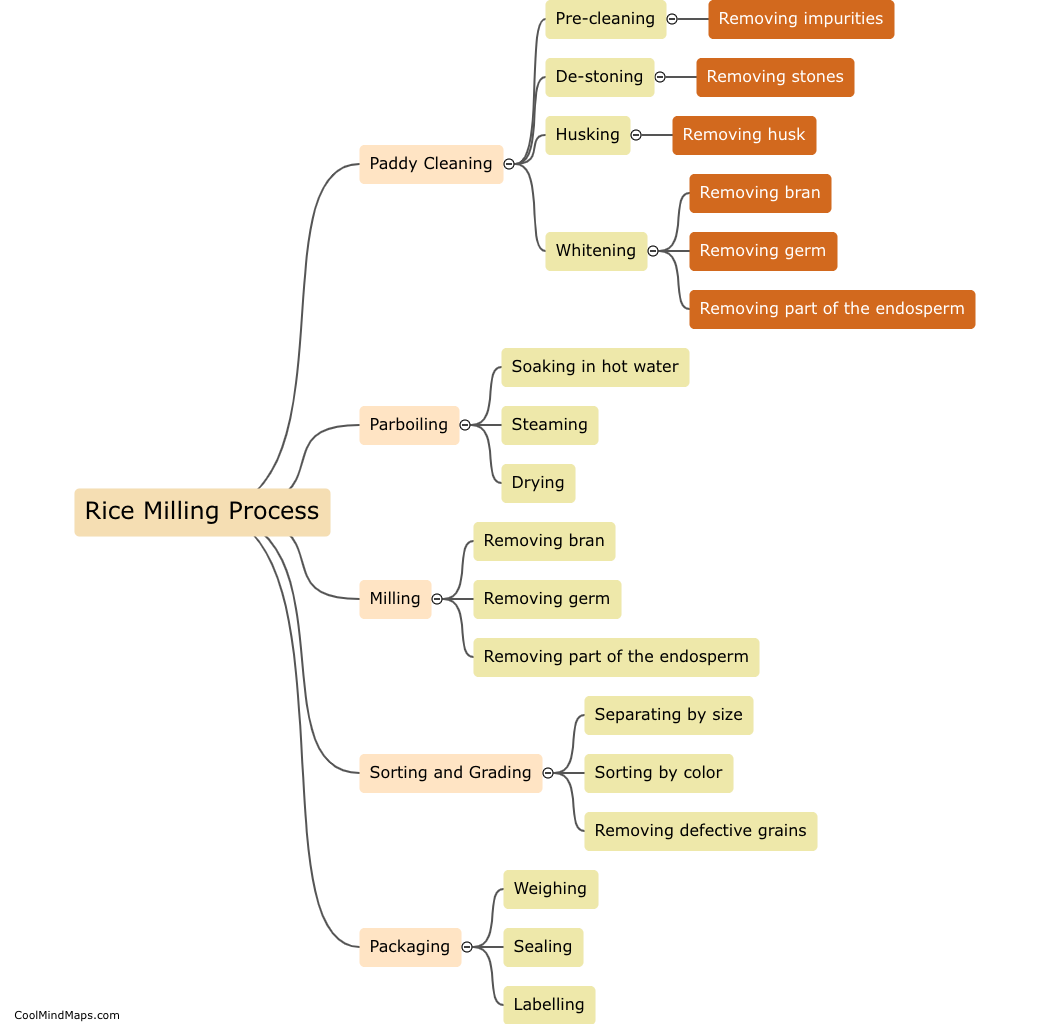

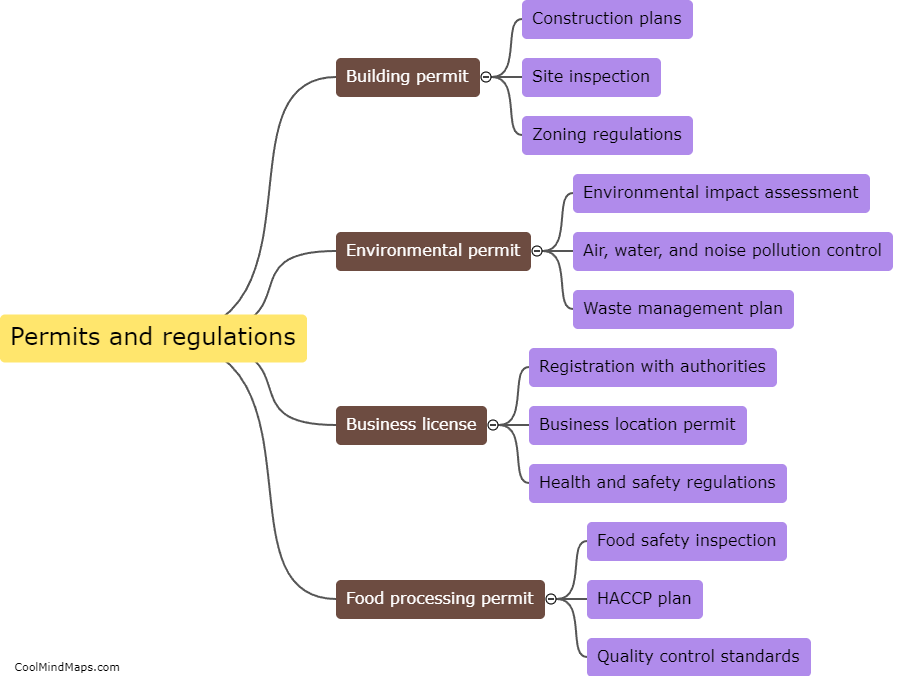

Operating a rice milling factory comes with its fair share of challenges. One key challenge is ensuring a consistent and high-quality output. This involves managing the rice milling process carefully to prevent any damage to the grains or loss of nutritional value. Additionally, securing a steady supply of high-quality paddy rice can be a challenge, as the quality directly affects the final product. Another hurdle is managing the complex machinery and equipment necessary for the milling process, as any breakdown or malfunction can significantly disrupt operations and lead to losses. Moreover, ensuring proper storage and packaging of the milled rice is crucial to prevent spoilage and preserve its quality. Lastly, complying with food safety regulations and implementing efficient waste management practices can be demanding tasks. Therefore, successfully operating a rice milling factory requires expertise, careful planning, and continuous monitoring to overcome these potential challenges.

This mind map was published on 30 July 2023 and has been viewed 121 times.