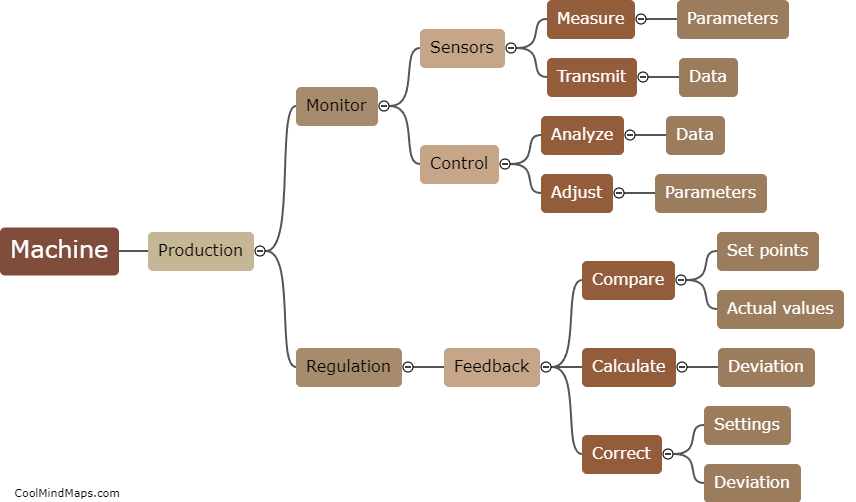

How does the production machine monitor and regulate production?

The production machine monitors and regulates production through a combination of advanced sensors, software algorithms, and control systems. These machines are equipped with sensors that gather data on various parameters such as speed, temperature, pressure, and quality. This data is then analyzed and processed by the software algorithms to detect any deviations from the desired production parameters. If any abnormalities are identified, the control systems intervene to regulate and correct the production process. This can involve adjustments to operating parameters, like adjusting speed or temperature, or even stopping the production if necessary. By continuously monitoring and regulating production, these machines ensure consistent quality, efficiency, and adherence to set standards, minimizing errors and maximizing productivity.

This mind map was published on 27 November 2023 and has been viewed 87 times.