How can lean production improve efficiency?

Lean production is a management philosophy that focuses on minimizing waste and maximizing value for the customer. By implementing lean principles, such as the elimination of non-value-added activities and continuous improvement, organizations can significantly improve their efficiency. Lean production streamlines processes, reduces cycle times, and eliminates unnecessary steps, which leads to faster production times and increased productivity. Additionally, lean production promotes employee involvement and empowerment, fostering a culture of continuous improvement and innovation. By optimizing resources and minimizing waste, lean production ultimately enhances efficiency by ensuring that every aspect of the production process adds value to the final product or service.

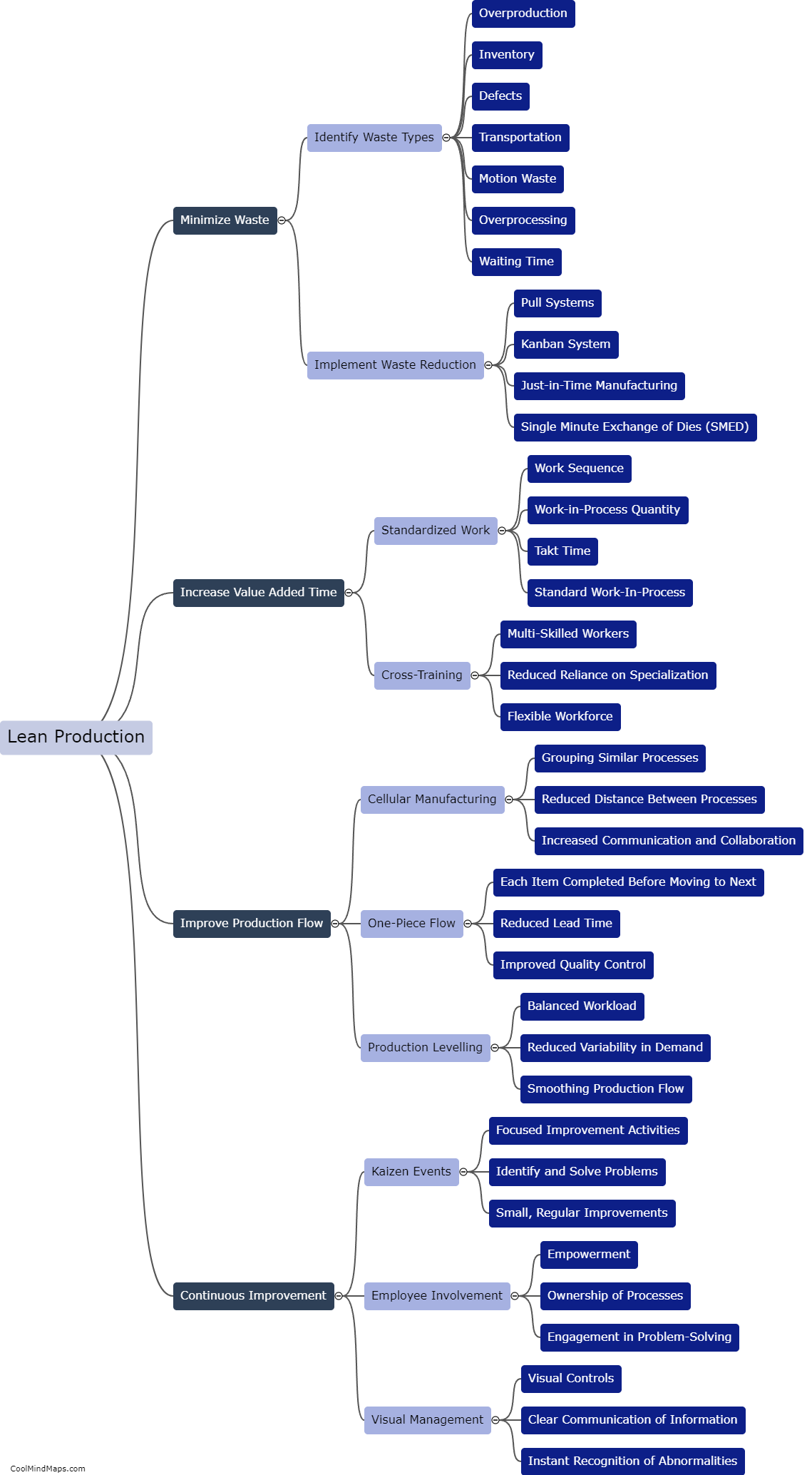

This mind map was published on 10 November 2023 and has been viewed 93 times.