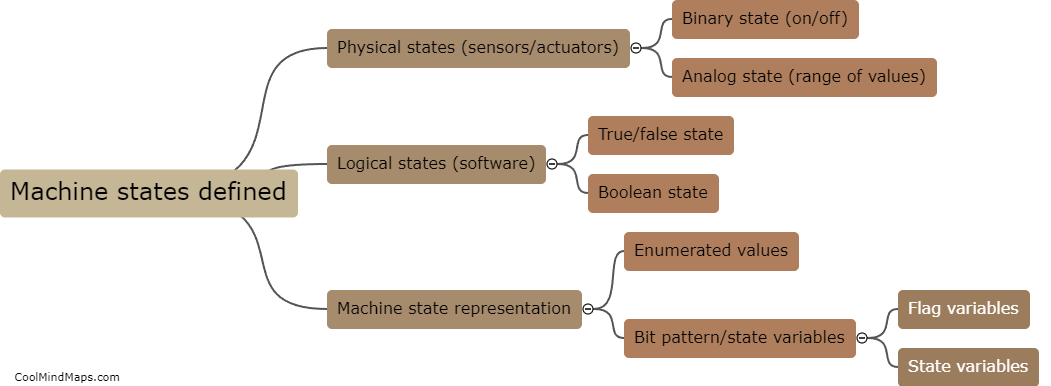

What are the maintenance steps for a production machine?

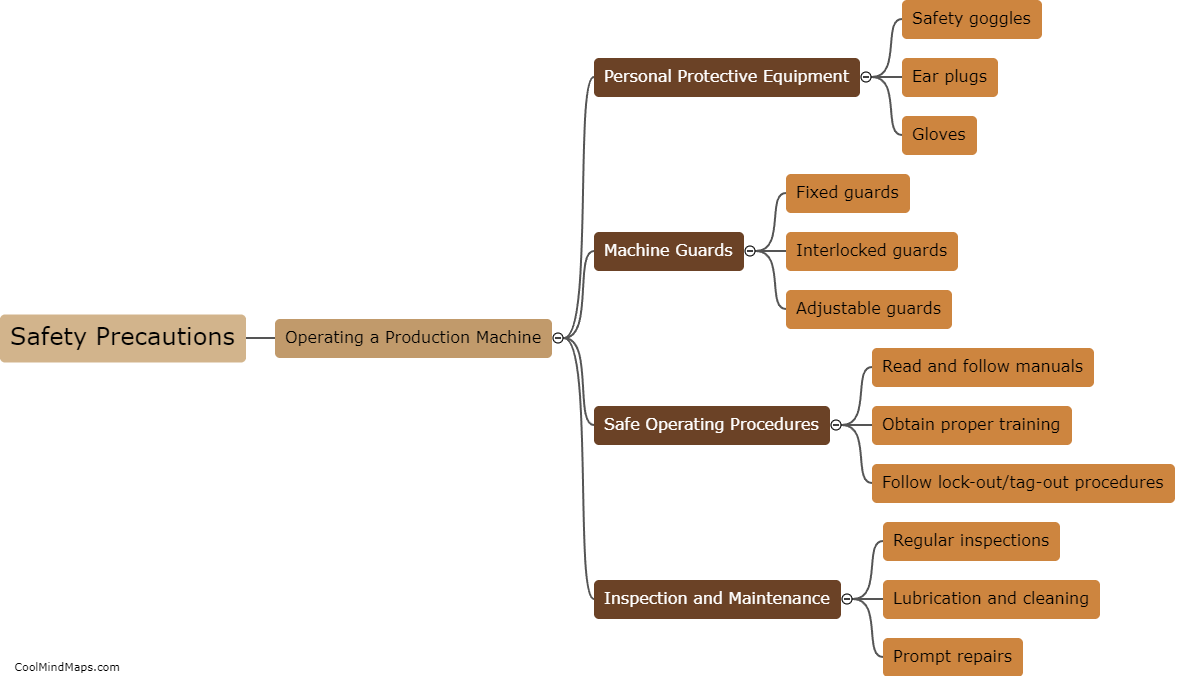

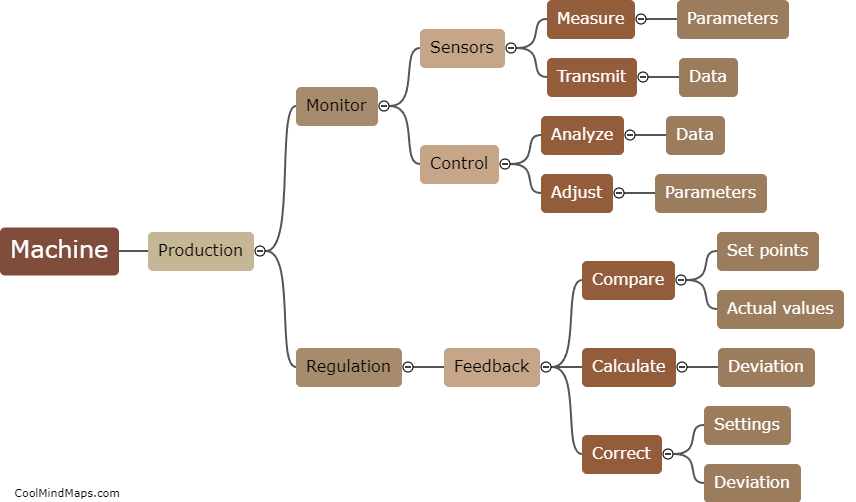

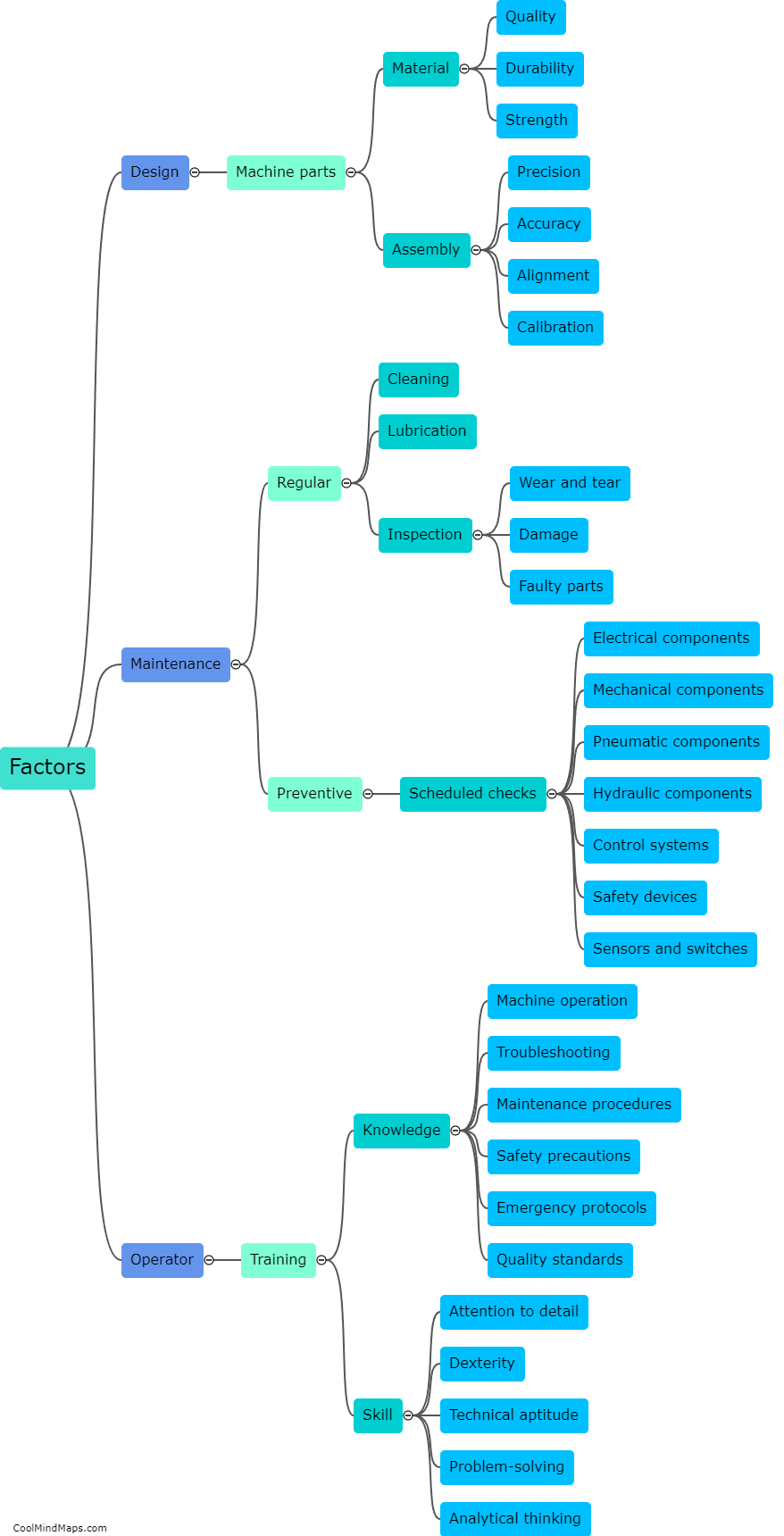

Maintaining a production machine is crucial for ensuring its optimal performance and longevity. The maintenance steps typically involve several key tasks. First, regular cleaning of the machine is essential to remove any dust, debris, or buildup that may impede its functioning. Next, lubrication of moving parts such as gears, bearings, and belts should be done according to the manufacturer's guidelines. Additionally, inspecting and replacing worn-out or damaged parts is vital to prevent breakdowns and maintain smooth operation. Moreover, calibration of sensors and controls should be performed periodically to ensure accuracy and consistency. Finally, conducting regular preventive maintenance, including checking for leaks, testing safety features, and verifying electrical connections, is crucial to identify potential issues and address them proactively. Following these maintenance steps diligently can not only optimize the machine's productivity but also reduce the risk of costly repairs and downtime.

This mind map was published on 27 November 2023 and has been viewed 82 times.