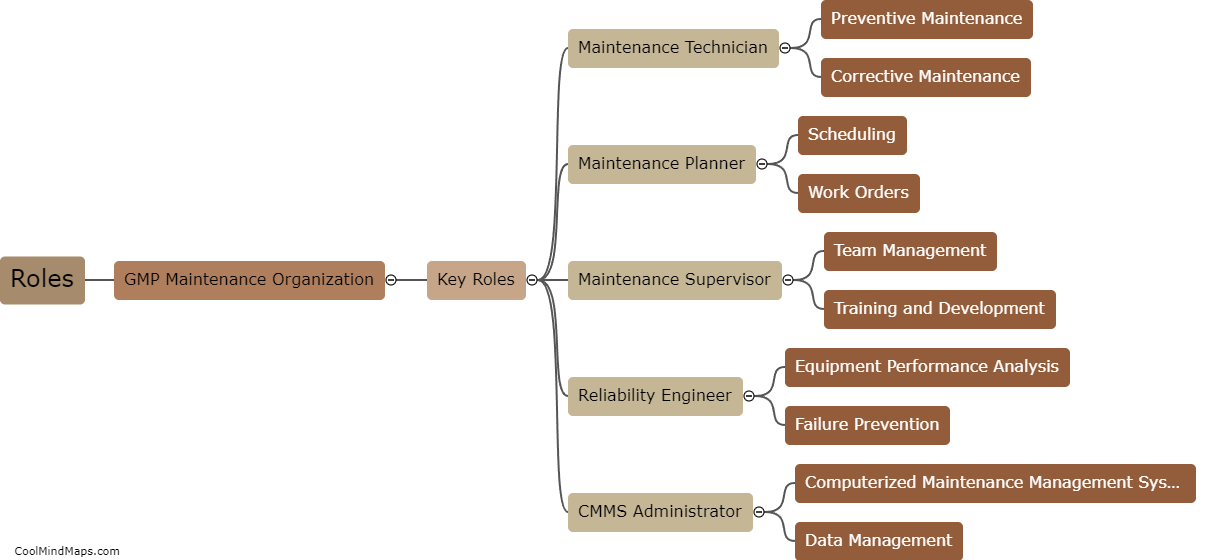

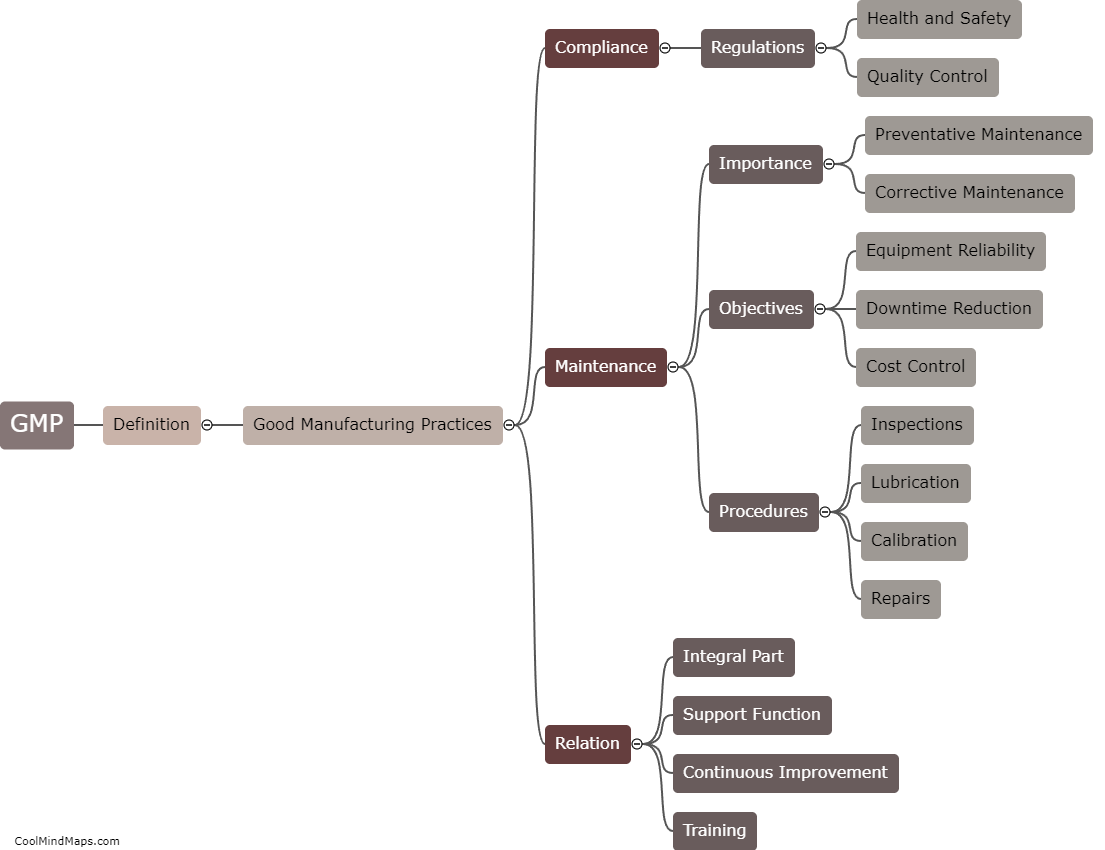

What is GMP and how does it relate to maintenance?

GMP, or Good Manufacturing Practice, is a system of manufacturing standards that ensure the quality and safety of products in various industries, including pharmaceuticals, food, and cosmetics. It is a set of guidelines and regulations that address every aspect of the manufacturing process, from facility design to documentation and personnel training. GMP emphasizes maintaining a high level of cleanliness, hygiene, and organization in production areas. When it comes to maintenance, GMP plays a crucial role in ensuring that equipment, machinery, and facilities are properly maintained, calibrated, and serviced to minimize the risk of product contamination, equipment failure, and production delays. Adhering to GMP standards for maintenance helps companies maintain product quality, compliance, and customer satisfaction.

This mind map was published on 19 November 2023 and has been viewed 122 times.