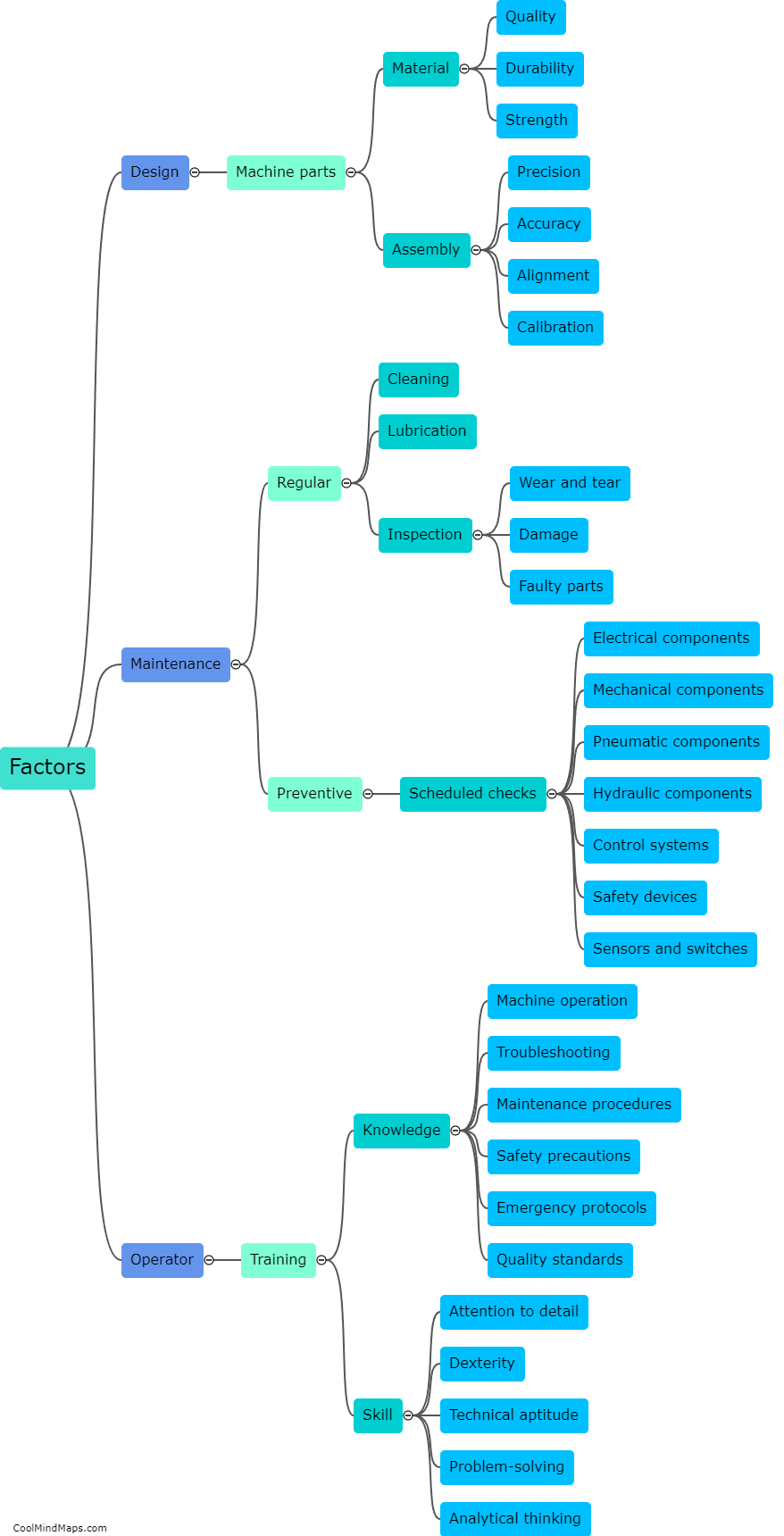

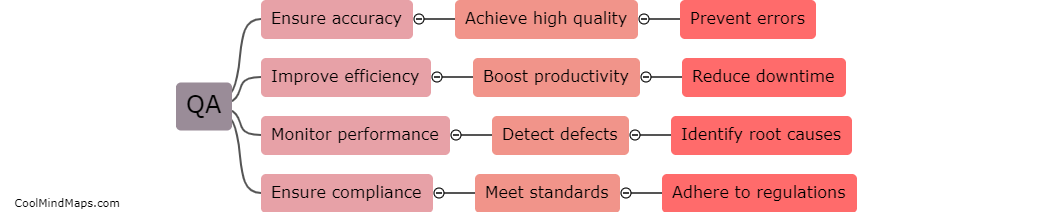

What is the importance of QA & QC in machine operation?

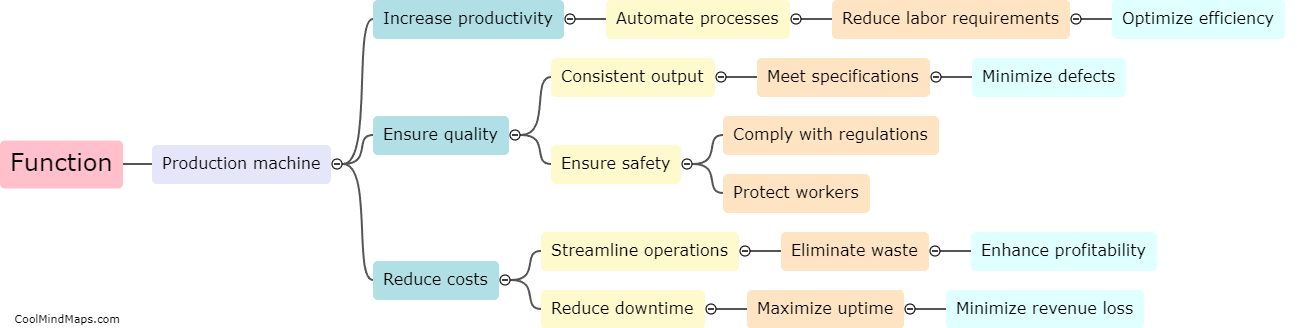

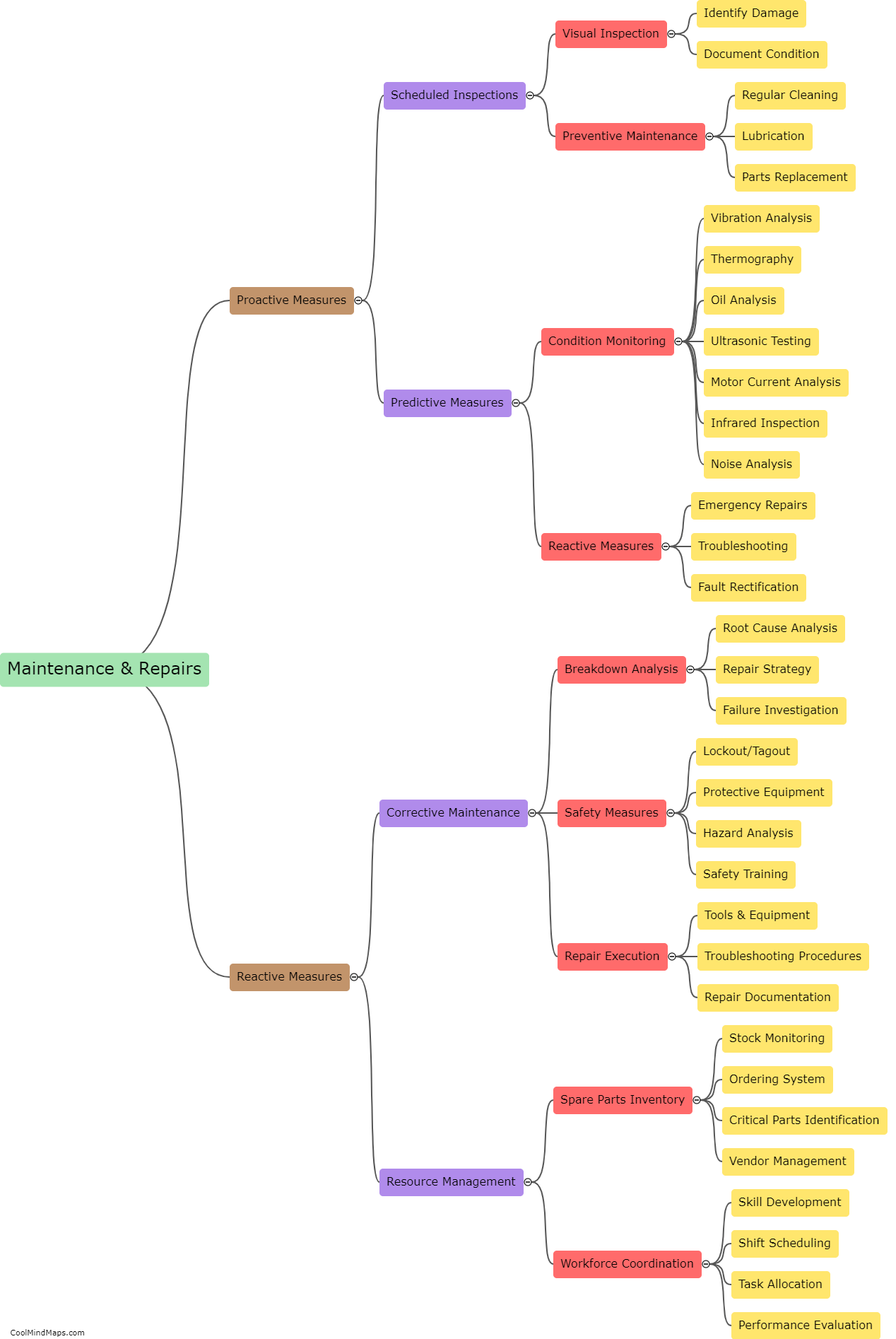

QA (Quality Assurance) and QC (Quality Control) play a crucial role in machine operation. QA focuses on preventing defects and ensuring that the final product meets the desired standards. It involves establishing processes, procedures, and guidelines to guarantee consistent quality throughout the production process. On the other hand, QC involves inspecting and testing the product to identify any defects or deviations from specifications. It ensures that the final product meets the desired quality standards before it is released. By implementing effective QA and QC practices, machine operators can maintain the reliability, safety, and performance of their machines, avoid costly breakdowns or accidents, and improve overall customer satisfaction. These practices also enable operators to continuously monitor and improve their processes, leading to increased efficiency and productivity in machine operation.

This mind map was published on 25 November 2023 and has been viewed 126 times.