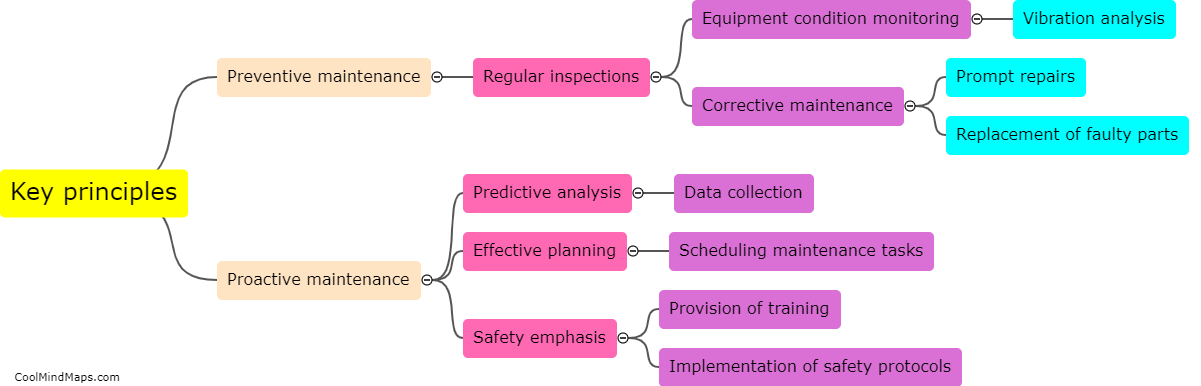

What are the key principles of maintenance management?

Maintenance management is a crucial aspect of ensuring the efficient and effective operation of any industrial facility or equipment. There are several key principles that serve as the foundation of successful maintenance management. Firstly, preventive maintenance is vital, as it involves regular inspections and maintenance activities to reduce the likelihood of equipment breakdowns and costly repairs. Secondly, proper planning and scheduling are essential to allocate resources efficiently and minimize downtime. Thirdly, effective communication is crucial in coordinating maintenance activities across different departments and ensuring everyone is aware of their roles and responsibilities. Additionally, the principle of continuous improvement involves regularly reviewing and evaluating maintenance processes to identify areas for improvement and implement strategies to enhance efficiency and reduce costs. Lastly, prioritization is necessary to allocate resources based on the criticality and impact of equipment failures, ensuring that maintenance efforts are focused on the most important assets. By adhering to these key principles, maintenance management can optimize operations, prolong the lifespan of assets, and enhance productivity.

This mind map was published on 13 January 2024 and has been viewed 100 times.