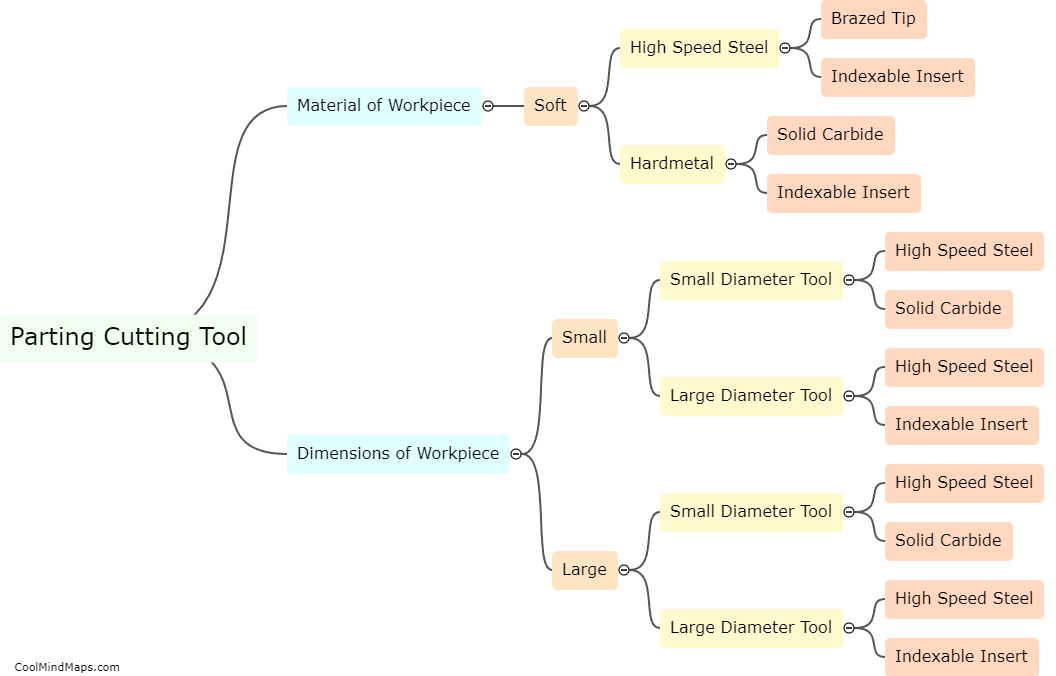

How to select the right parting cutting tool for the job?

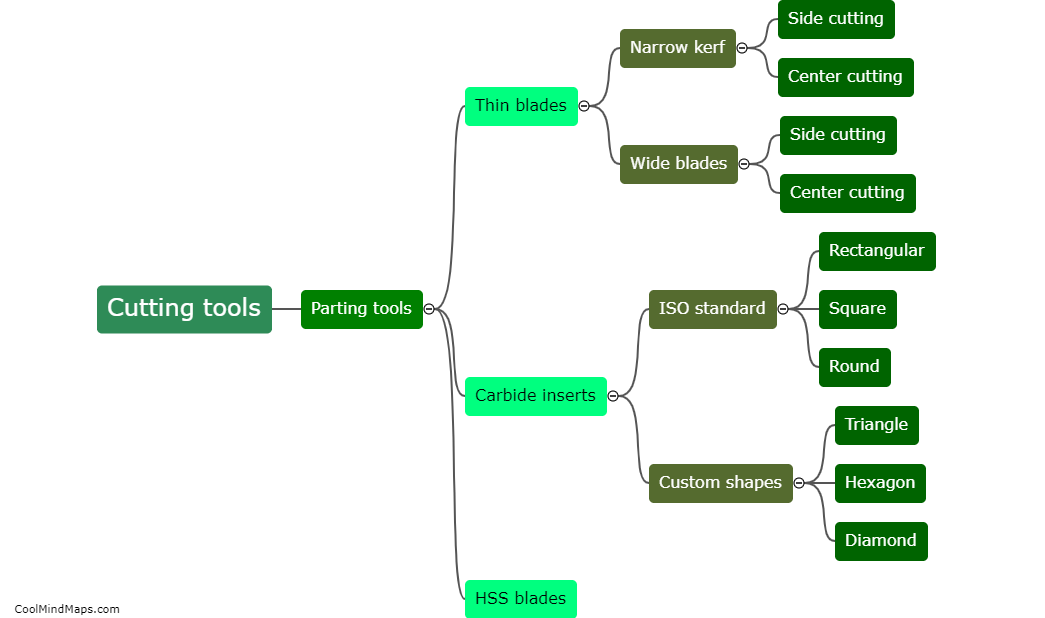

Selecting the right parting cutting tool for a specific job is crucial to achieve precision and efficiency. There are several factors to consider when making this decision. First, understanding the material being cut is vital. Different materials require different cutting tools with specific geometries, coatings, and inserts to optimize performance. Second, evaluating the depth and width of the cut is essential. The tool should be capable of reaching the desired dimensions without sacrificing stability or causing excessive tool wear. Third, considering the machine's capabilities and limitations is necessary. Ensure that the selected parting cutting tool is suitable for the type and power of the machine being used. Lastly, aligning price with value is important as expensive tools might not always be necessary for the job while inexpensive options may compromise precision. By carefully evaluating these factors, one can select the most appropriate parting cutting tool for a specific job, maximizing productivity and achieving top-quality results.

This mind map was published on 10 November 2023 and has been viewed 84 times.