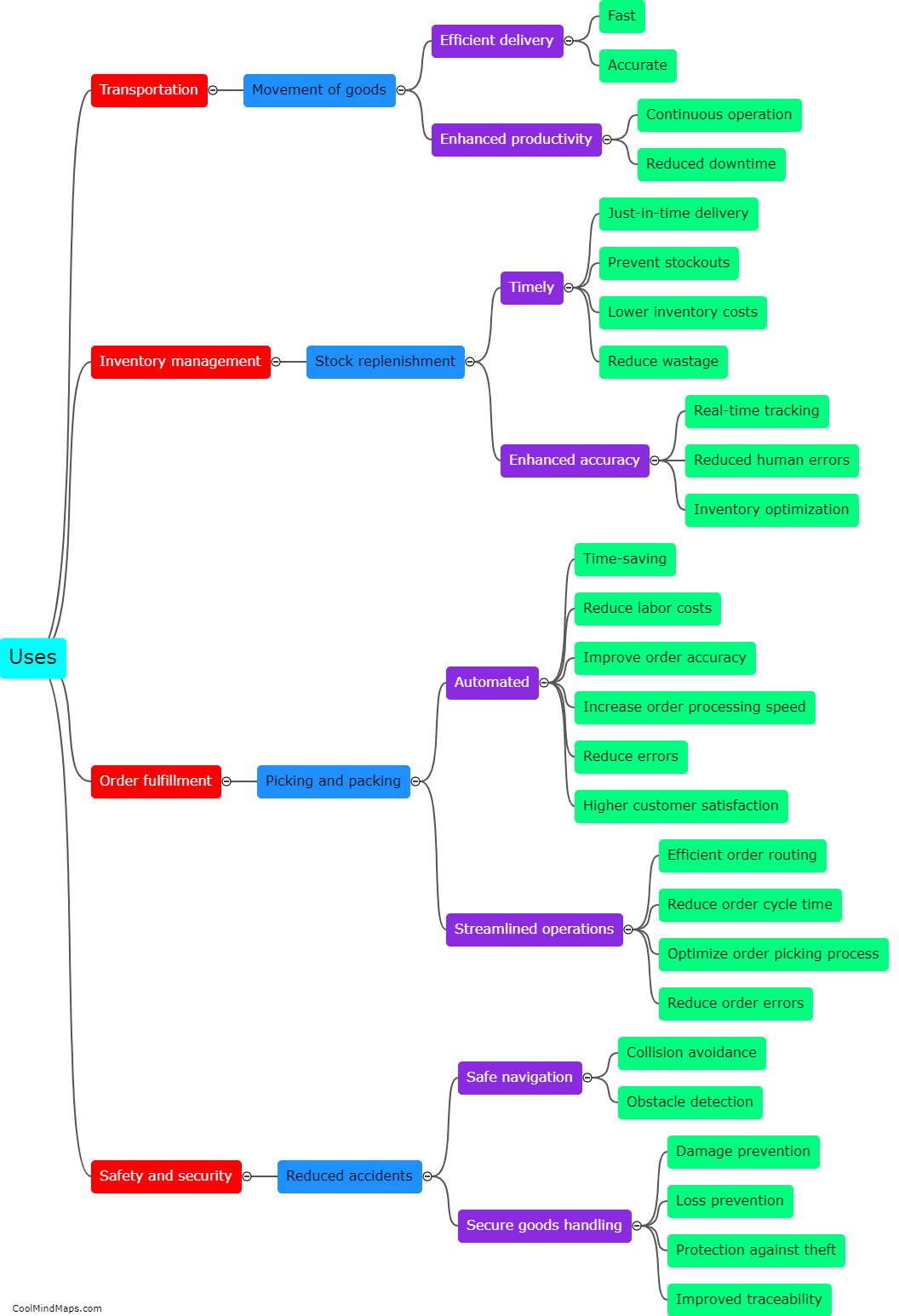

What are the uses of AGVs in warehouses?

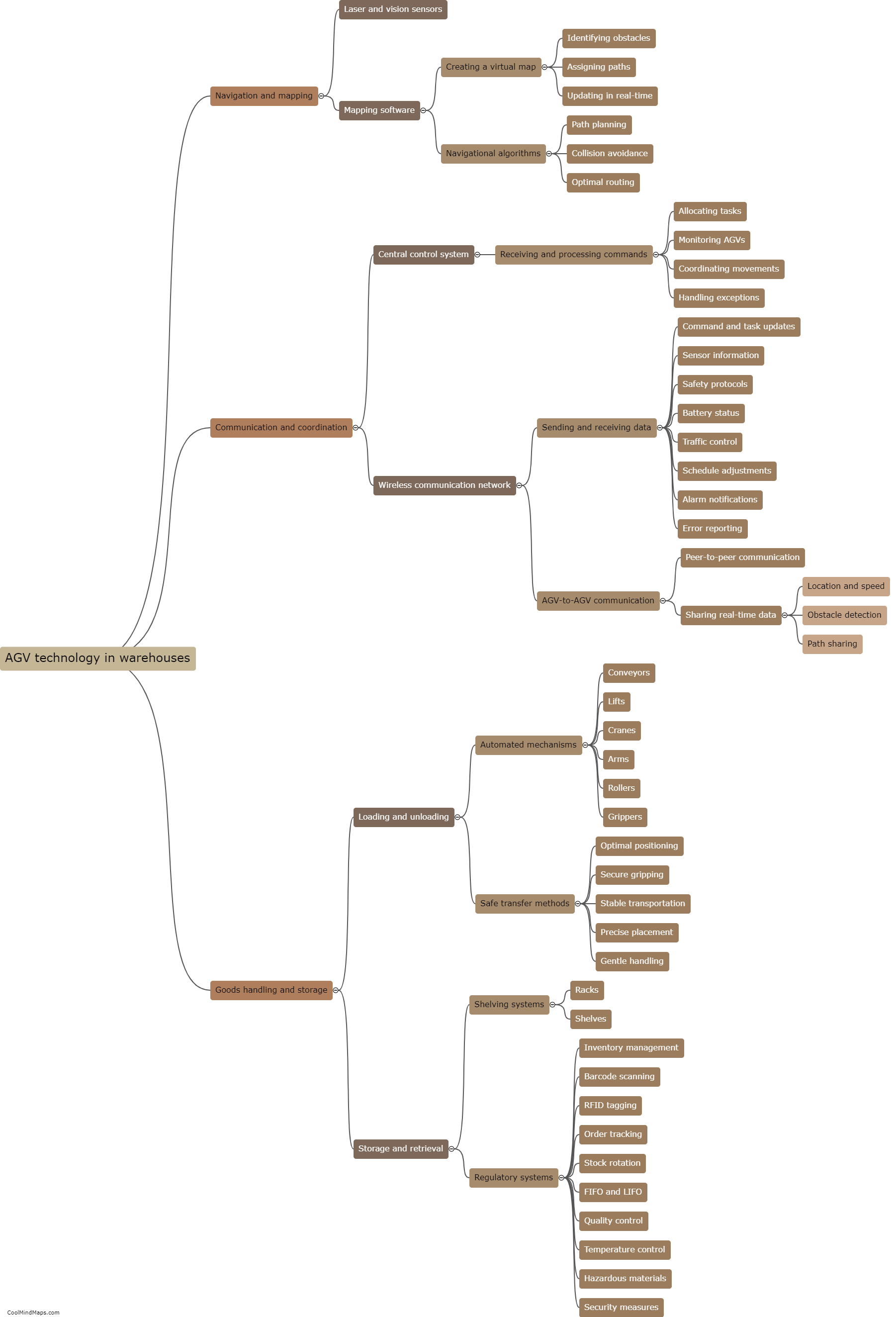

Automated Guided Vehicles (AGVs) are becoming increasingly popular in warehouses due to their numerous uses and benefits. AGVs are essentially robotic vehicles that are programmed to carry out specific tasks with minimal human intervention. In warehouses, AGVs are primarily used for material handling, such as transporting goods from one location to another, loading and unloading pallets, and replenishing stock. They can navigate the warehouse environment autonomously, following pre-programmed routes or using sensors to avoid obstacles. AGVs help improve operational efficiency by reducing human labor, minimizing errors, and accelerating the movement of goods. They also contribute to a safer work environment by eliminating the risks associated with heavy lifting and manual handling. Additionally, AGVs provide real-time tracking of inventory, optimizing inventory control and allowing for better planning and decision-making. Overall, the uses of AGVs in warehouses lead to increased productivity, cost savings, and improved customer satisfaction.

This mind map was published on 17 January 2024 and has been viewed 95 times.