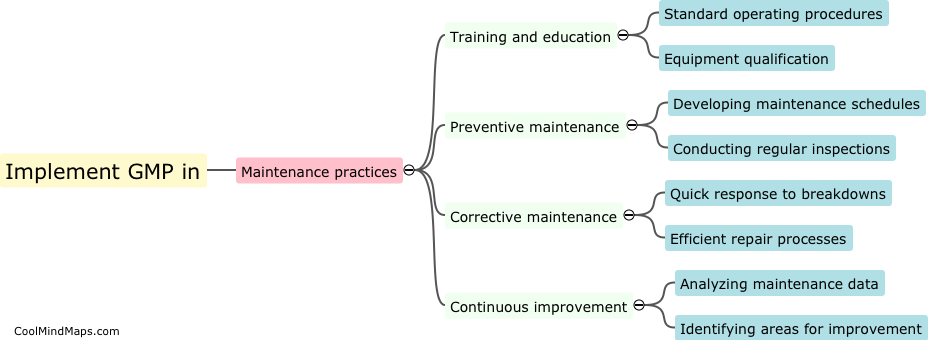

How to implement GMP in maintenance practices?

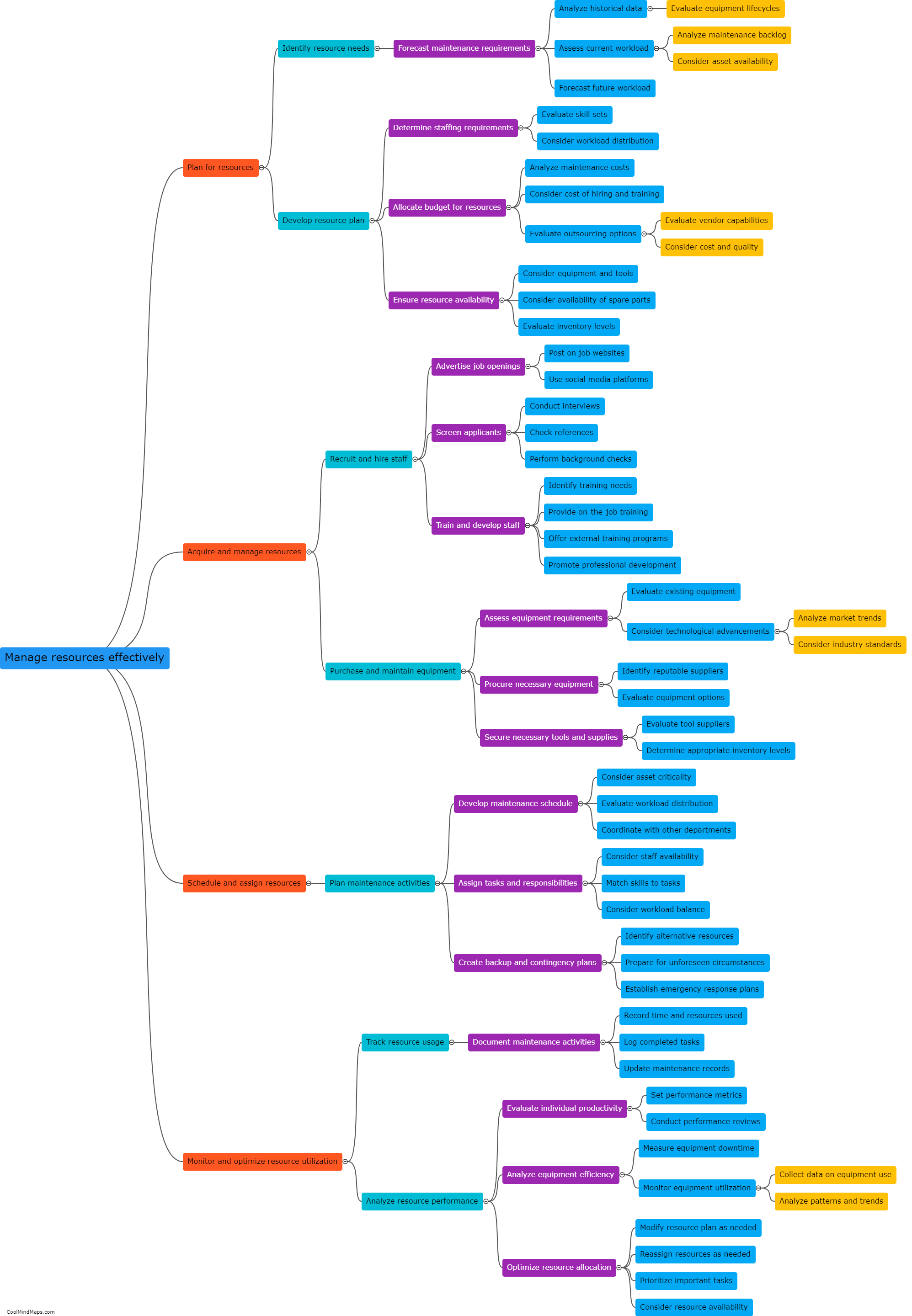

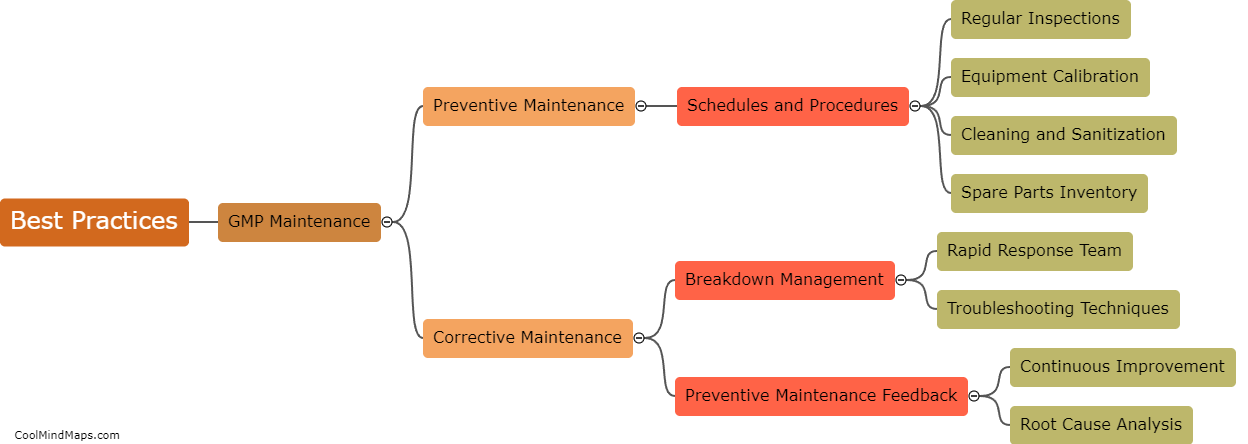

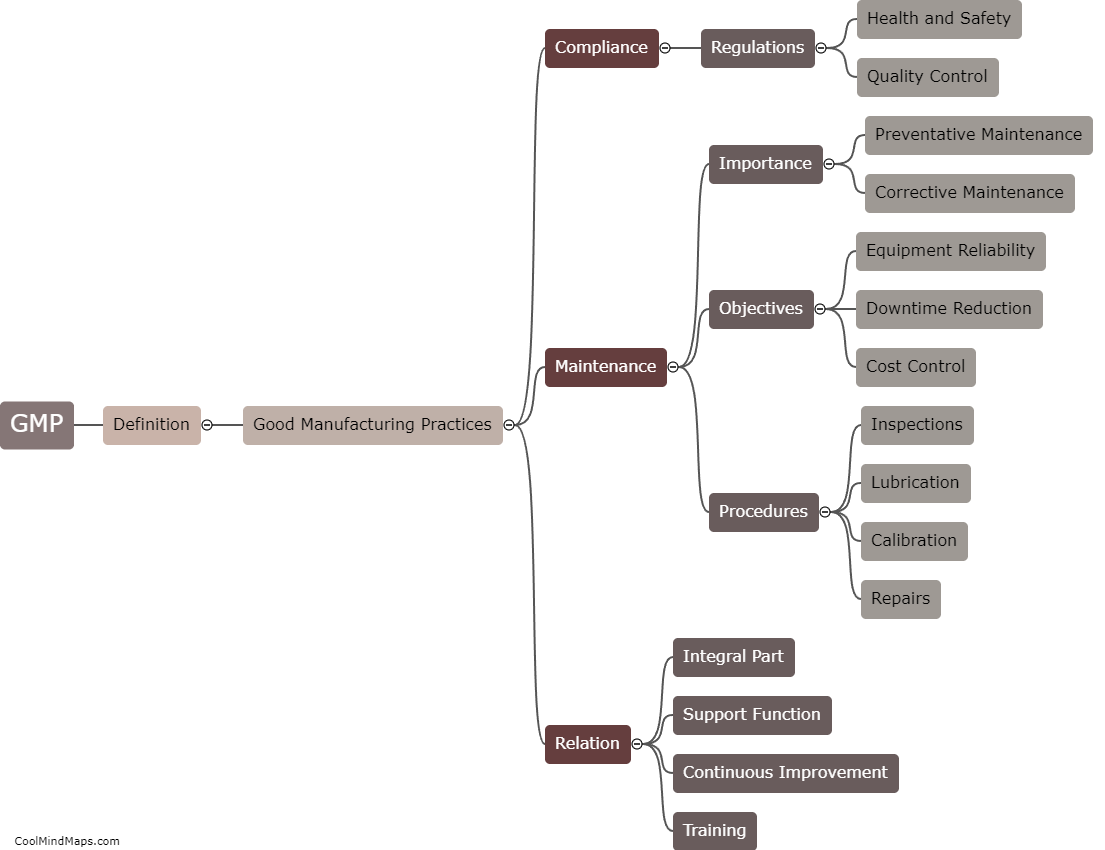

Implementing Good Manufacturing Practices (GMP) in maintenance practices is crucial for ensuring product quality, safety, and the overall efficiency of manufacturing operations. Firstly, it is important to develop and document comprehensive maintenance procedures that adhere to GMP guidelines. This involves creating detailed protocols for equipment cleaning, calibration, and preventive maintenance. Regular training sessions should be conducted for maintenance staff to educate them about GMP requirements and to ensure they understand the importance of following established procedures. Additionally, it is essential to establish a robust documentation system that includes maintenance logs, equipment history records, and any relevant supplier information. Regular audits and inspections should be conducted to monitor compliance with GMP standards and identify areas for improvement. By effectively implementing GMP in maintenance practices, companies can maintain optimal manufacturing conditions, minimize downtime, and achieve a high level of product quality and regulatory compliance.

This mind map was published on 16 November 2023 and has been viewed 118 times.