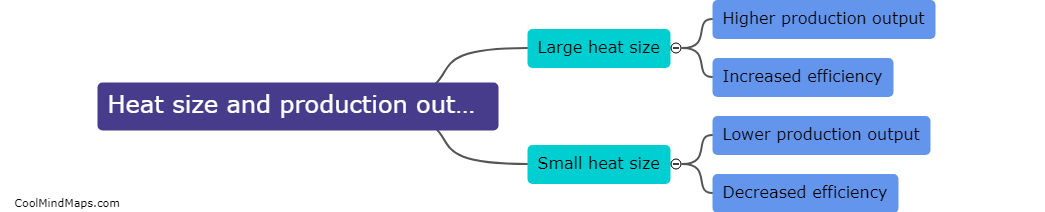

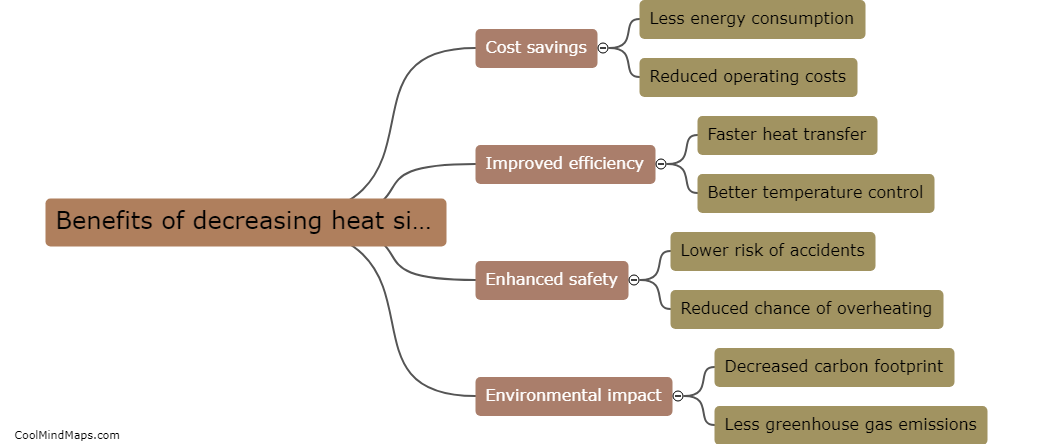

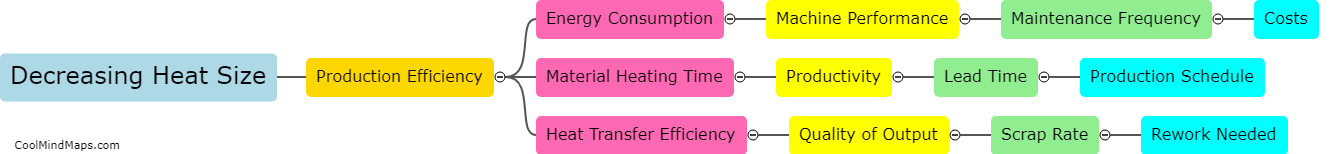

How does decreasing heat size affect production efficiency?

Decreasing heat size can have a direct impact on production efficiency in various ways. Smaller heat sizes typically allow for better control over the manufacturing process, resulting in more consistent and higher quality products. Additionally, smaller heat sizes can lead to shorter cycle times and quicker turnaround times, ultimately increasing overall production output. However, smaller heat sizes may also result in higher setup costs and increased handling requirements, which can potentially offset some of the efficiency gains. Overall, finding the optimal heat size for a given production process is crucial in maximizing efficiency and productivity.

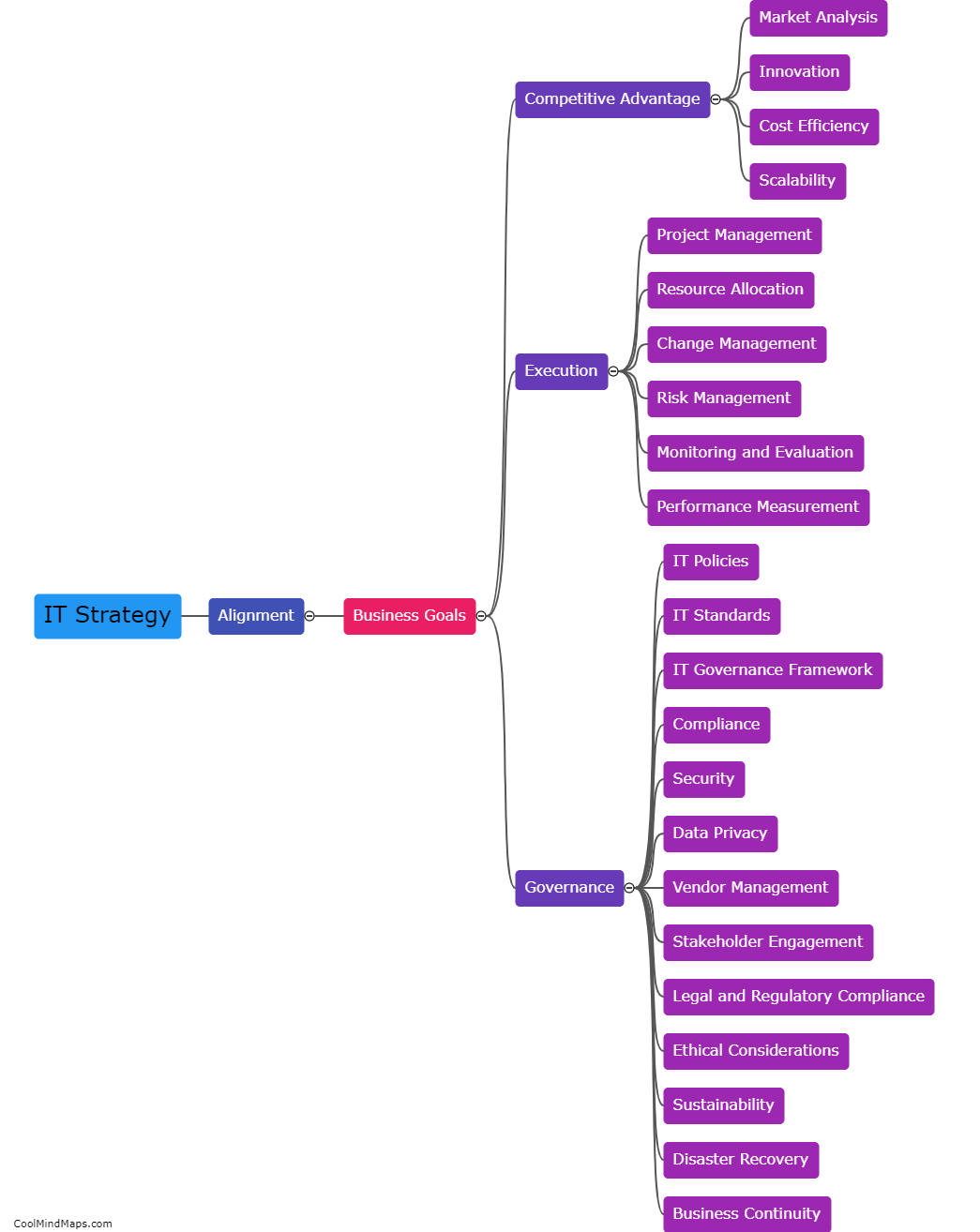

This mind map was published on 31 July 2024 and has been viewed 73 times.