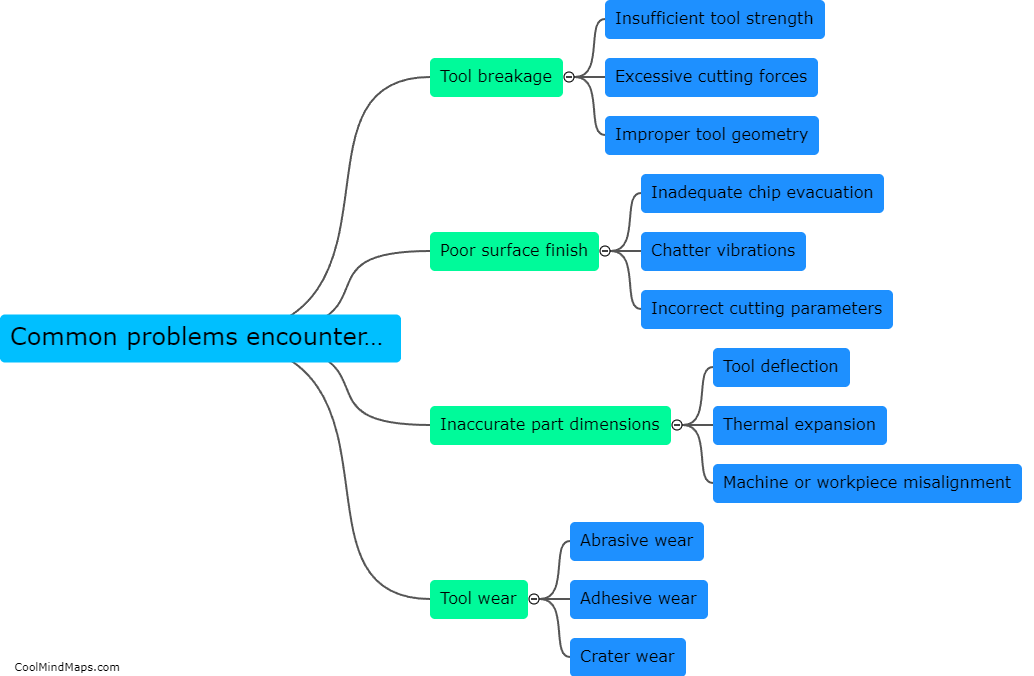

What are the common problems encountered with parting cutting tools?

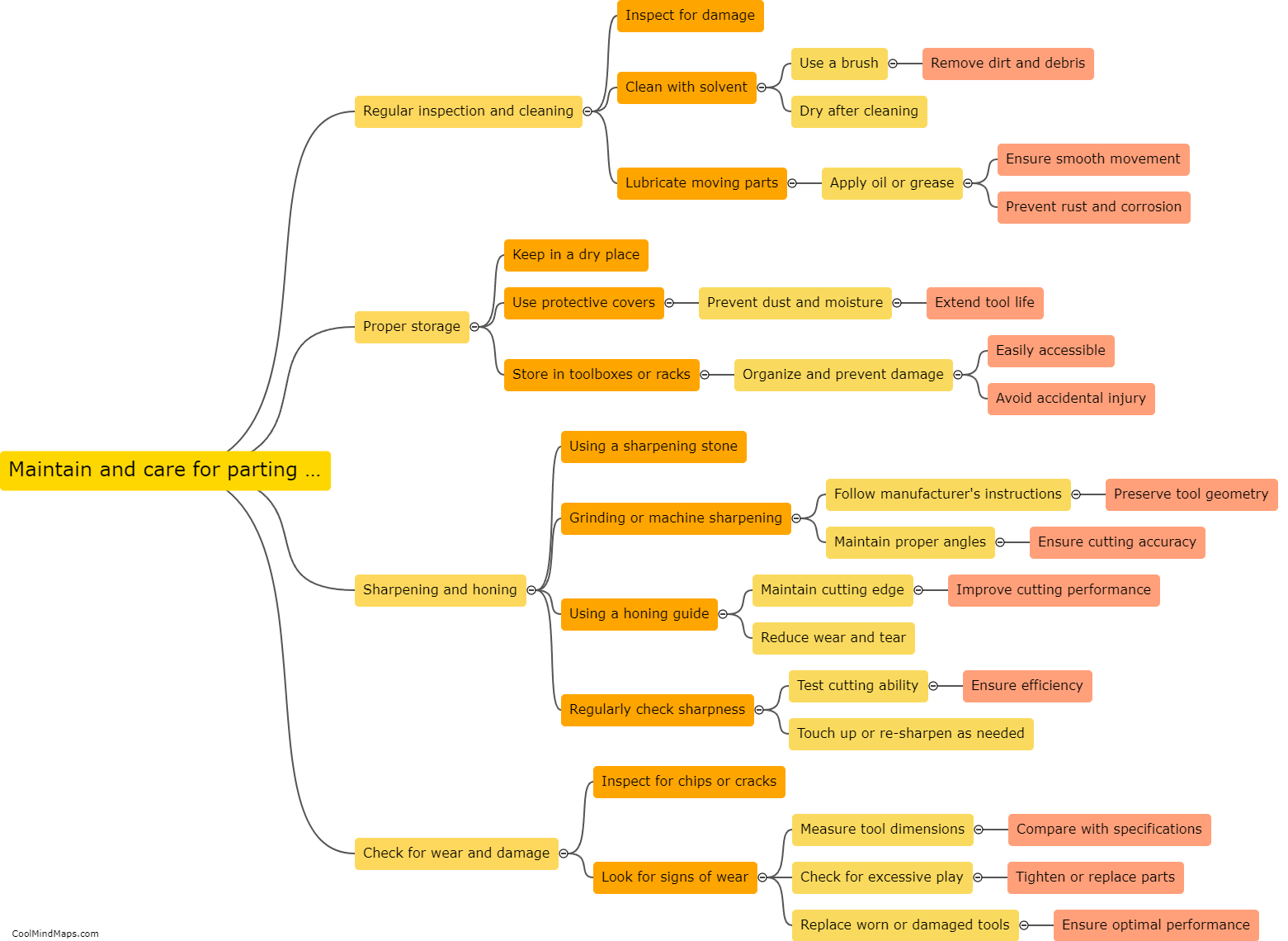

One common problem encountered with parting cutting tools is tool wear. Parting tools are subjected to significant forces and high temperatures, which can cause the cutting edges to wear down quickly. This can result in poor surface finish, increased cutting forces, and reduced tool life. Another issue is chip control. Parting operations produce long, continuous chips that can wrap around the workpiece or tool, leading to chip jamming or tool breakage. Additionally, tool deflection can occur due to the high cutting forces involved in parting, leading to inaccurate cuts or chatter marks on the workpiece. To address these problems, proper selection of cutting tool materials, regular tool maintenance, and optimization of cutting parameters are essential.

This mind map was published on 10 November 2023 and has been viewed 85 times.