What are the benefits of using heat treatment in aircraft material manufacturing?

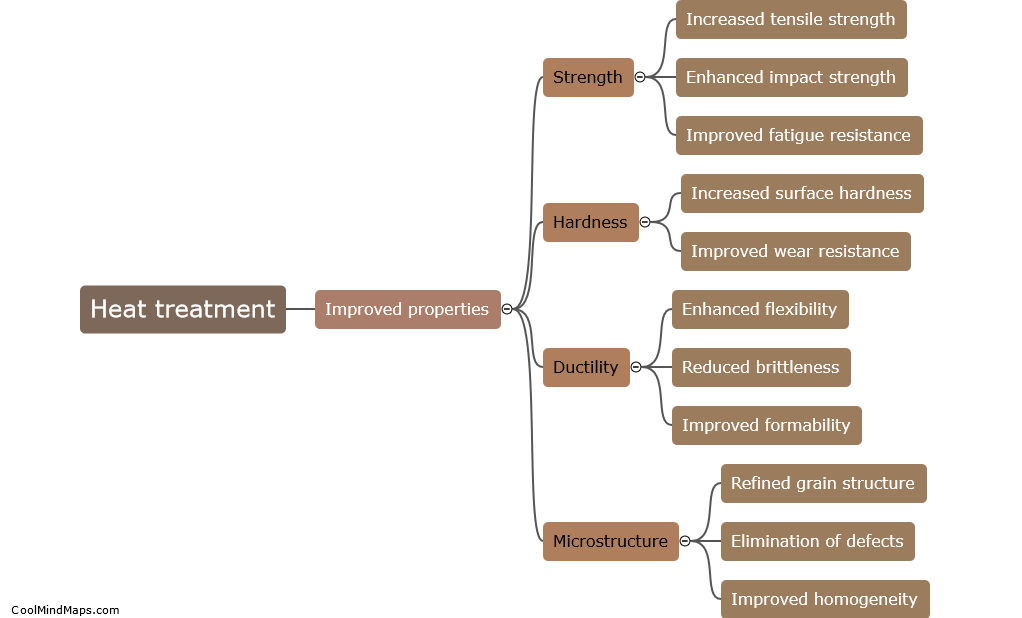

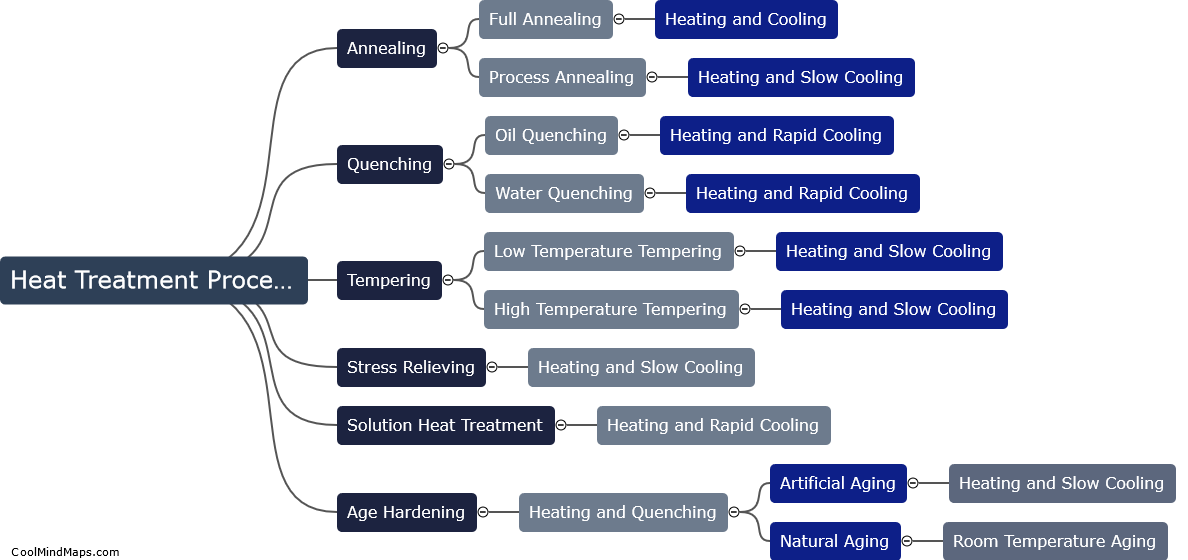

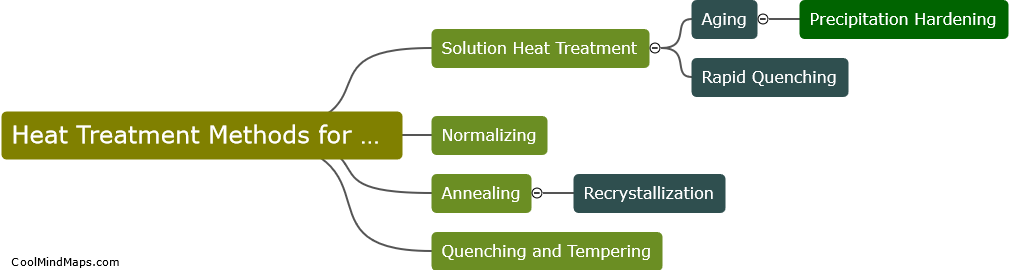

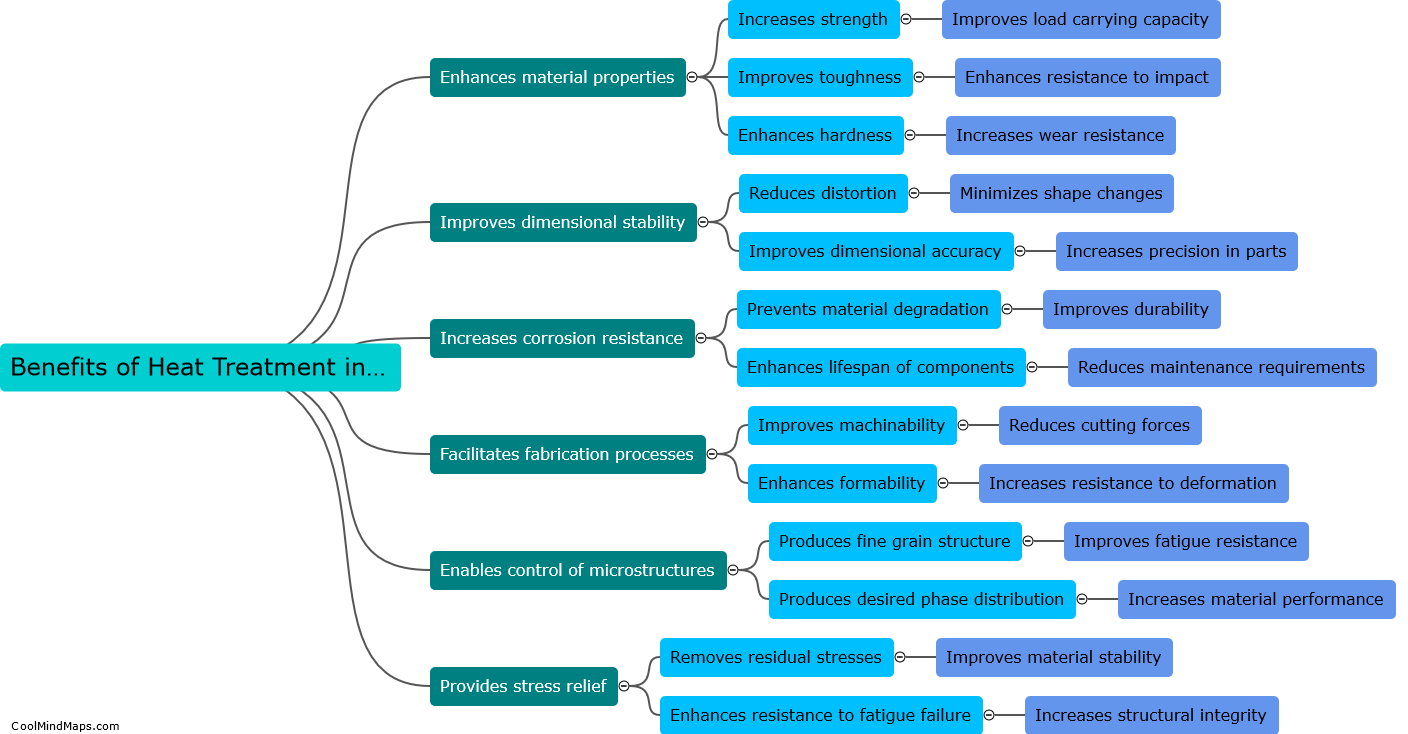

Heat treatment is a crucial aspect of aircraft material manufacturing, offering a range of benefits that enhance the structural integrity and performance of the materials used in aircraft construction. One of the key advantages of heat treatment is the ability to improve the material's strength and hardness, thereby increasing its resistance to wear, fatigue, and damage caused by external forces and extreme operating conditions. Furthermore, heat treatment allows for the alteration of material properties, such as its ductility and toughness, making it more resistant to deformation and fracture. This enables the production of lightweight materials while maintaining their structural integrity. Additionally, heat treatment aids in the removal of residual stresses, which can improve the dimensional stability of aircraft components and reduces the risk of distortion or failure. Overall, the utilization of heat treatment techniques in aircraft material manufacturing results in stronger, more durable, and safer aircraft structures, ensuring enhanced operational performance and safety in the aviation industry.

This mind map was published on 16 August 2023 and has been viewed 109 times.