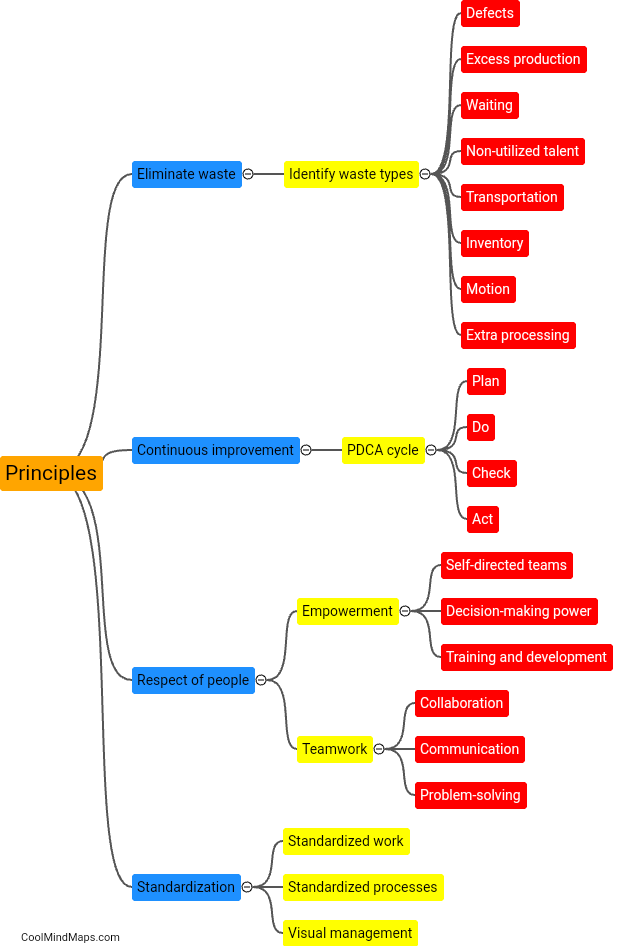

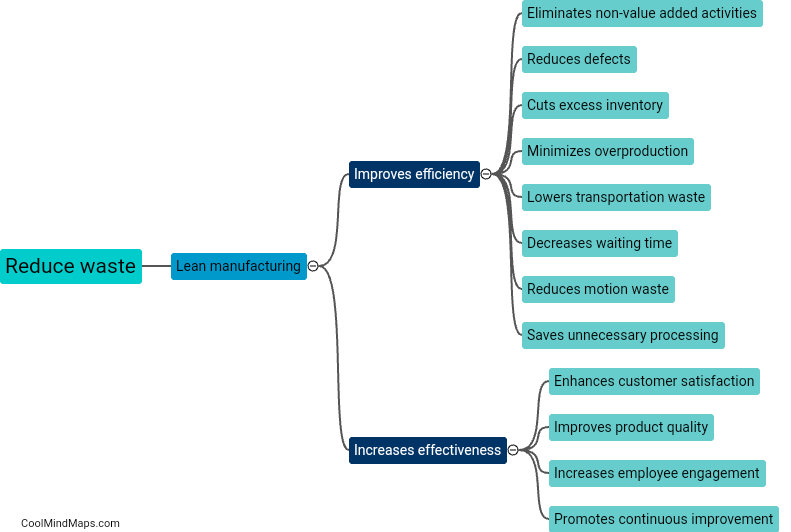

How does lean manufacturing reduce waste?

Lean manufacturing is a systematic approach that aims to minimize waste throughout the production process. By emphasizing efficiency and continuous improvement, lean manufacturing eliminates or reduces various types of waste, including overproduction, waiting time, excess inventory, defects, unnecessary transportation, motion, and over-processing. It achieves this by streamlining workflow, optimizing equipment and resources utilization, adopting just-in-time inventory management, empowering workers to eliminate non-value-added activities, and implementing quality control measures. Lean manufacturing ultimately maximizes productivity, improves product quality, and reduces costs by eliminating waste and focusing on value-adding activities.

This mind map was published on 29 November 2023 and has been viewed 101 times.