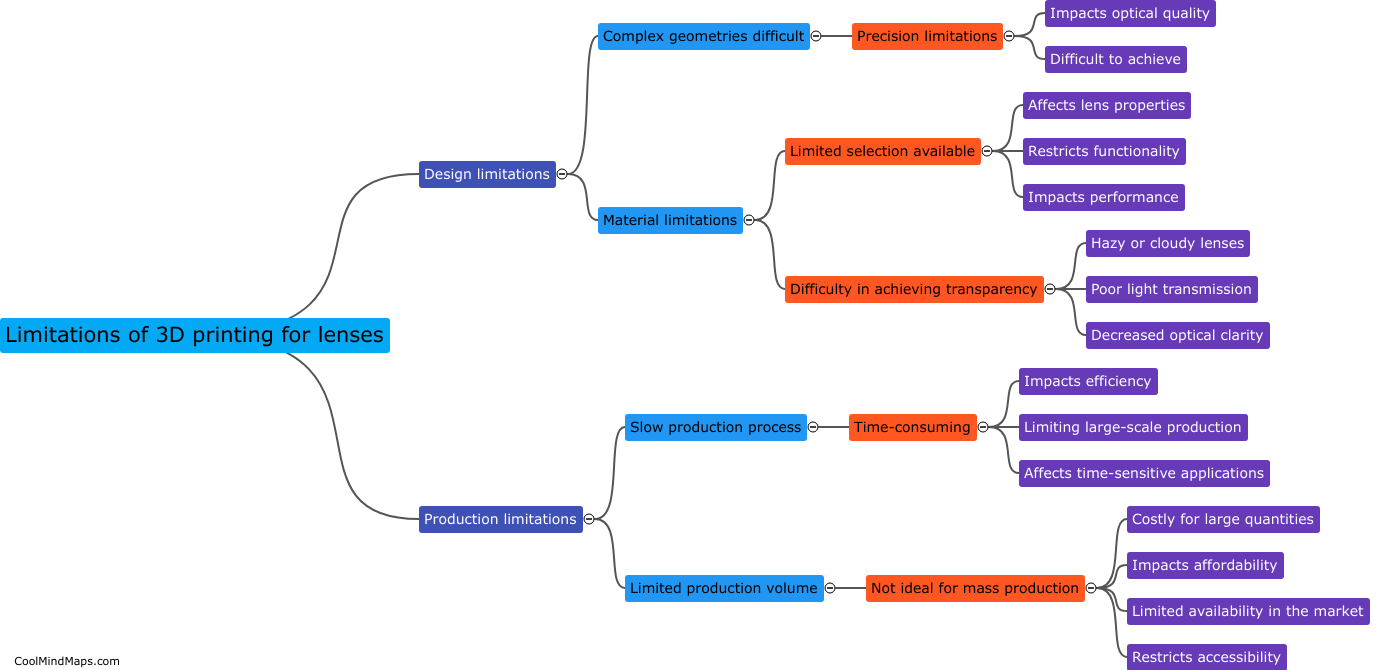

What are the limitations of 3D printing for lenses?

One of the limitations of 3D printing for lenses is the resolution constraints. While 3D printing technology has significantly advanced, it still cannot achieve the level of precision and smoothness required for high-quality lenses. The traditional lens manufacturing process involves precision grinding and polishing, which ensures excellent optical clarity and minimal distortion. Moreover, 3D printing materials often have limitations in terms of transparency and refractive index, making it difficult to produce lenses with the desired optical properties. Additionally, 3D printing has limitations in terms of complex lens designs, such as aspherical or multi-element lenses, which may require intricate shapes and highly precise curvatures that are challenging to achieve through additive manufacturing techniques. Therefore, although 3D printing has potential for lens production, it currently has limitations that prevent it from replacing traditional lens manufacturing methods entirely.

This mind map was published on 6 October 2023 and has been viewed 88 times.