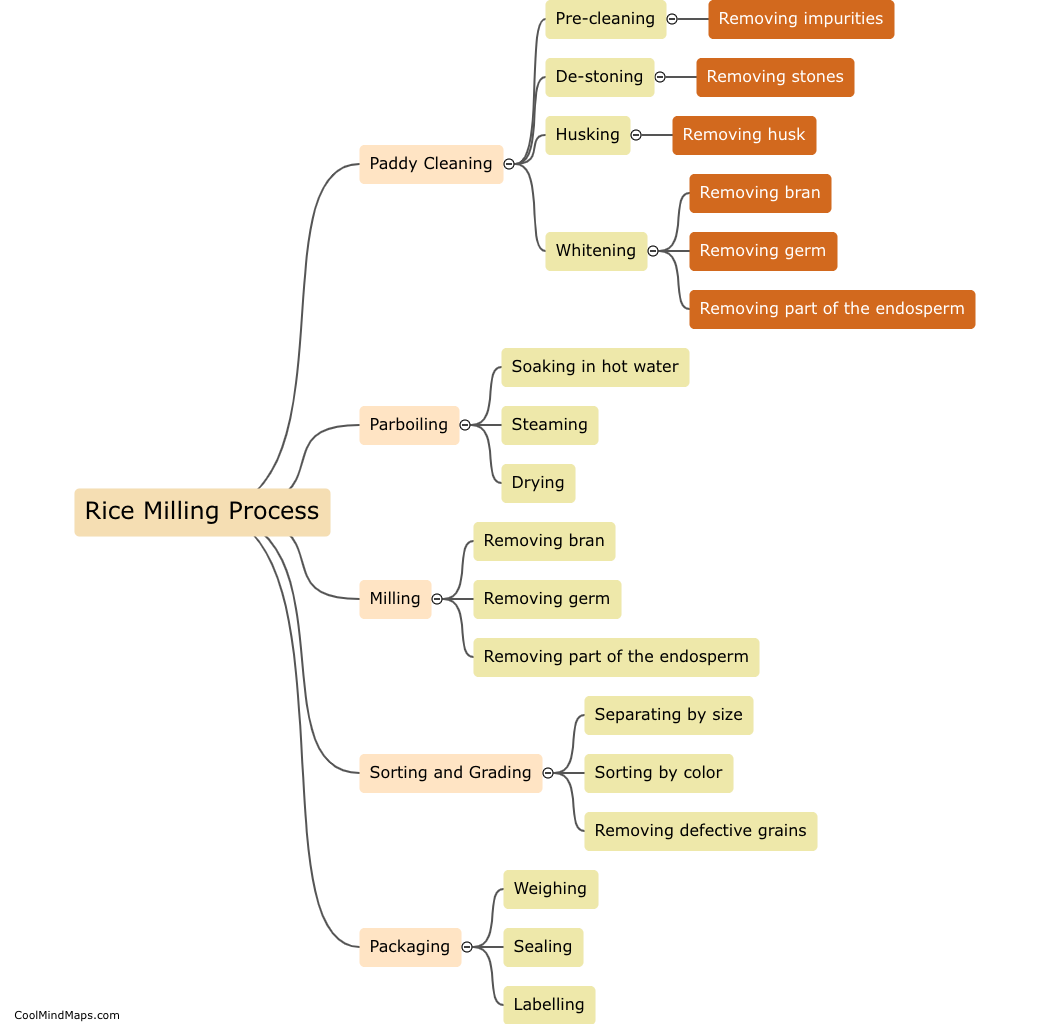

What are the key steps in the rice milling process?

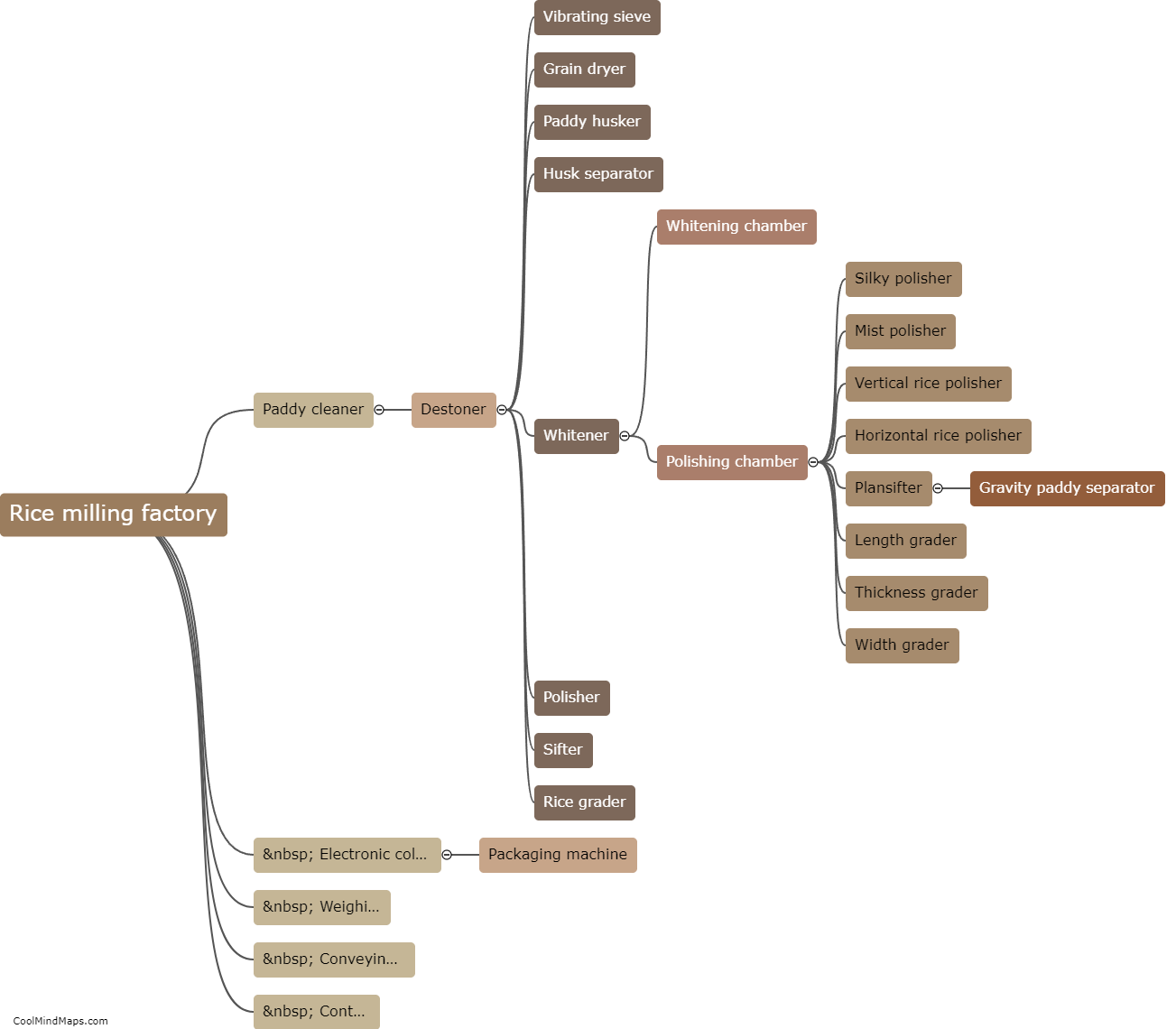

The rice milling process involves several key steps to transform raw paddy rice into cleaned, polished, and ready-to-consume rice. The first step is the cleaning process, where impurities such as dust, stones, and straw are removed from the paddy rice. Next, the paddy is dehusked in a machine called a husker, which removes the outer hull or husk from the rice grain. The resulting brown rice is then further polished in a machine called a whitener to remove the bran layer, resulting in white rice. After that, the rice is graded based on its size and quality using different sieves and screens. In the final step, the rice is sorted based on its appearance and color, removing any remaining impurities or defective grains. This process ensures that the rice produced is of high quality, nutritious, and visually appealing for consumption.

This mind map was published on 30 July 2023 and has been viewed 111 times.