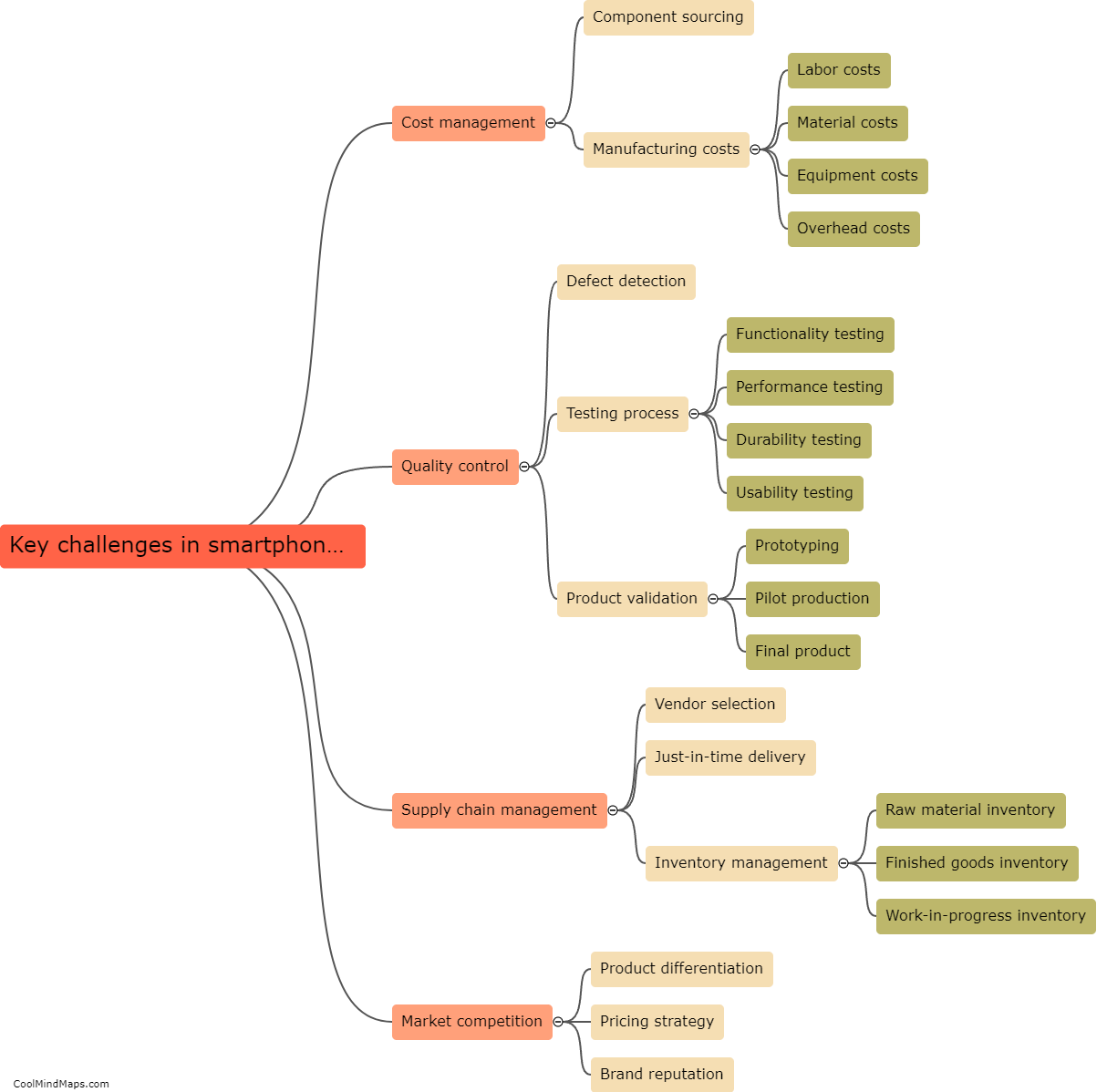

What are the key challenges in maintaining quality in smartphone manufacturing?

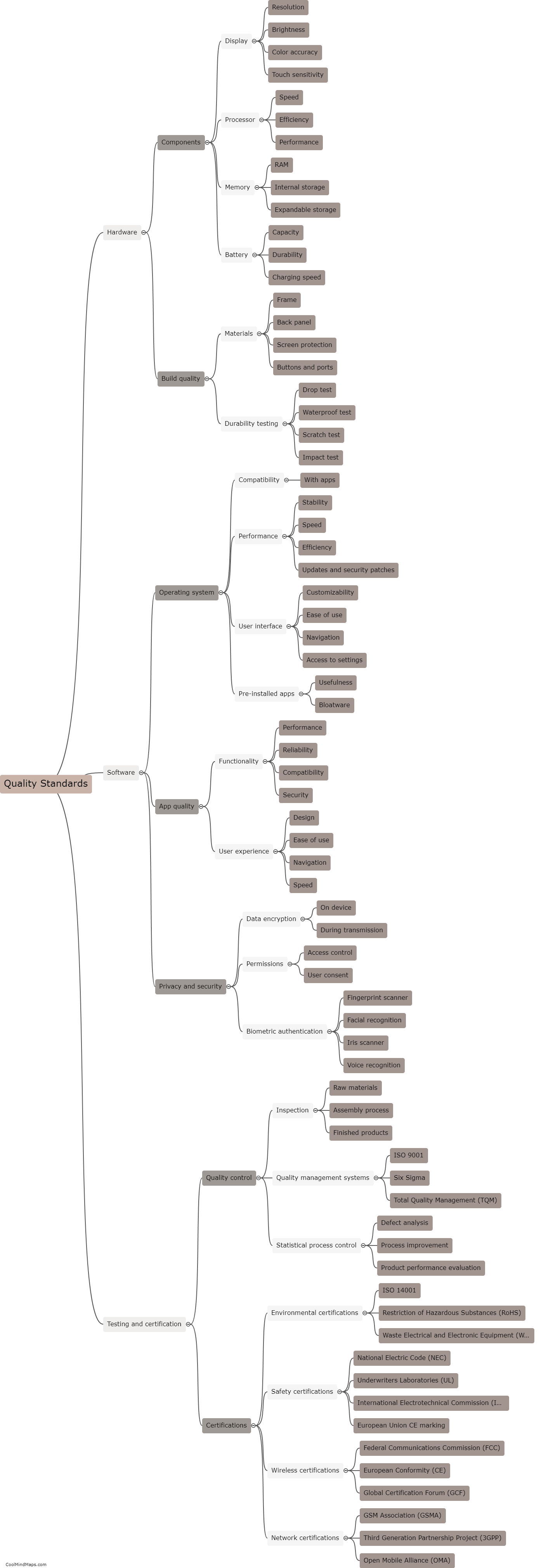

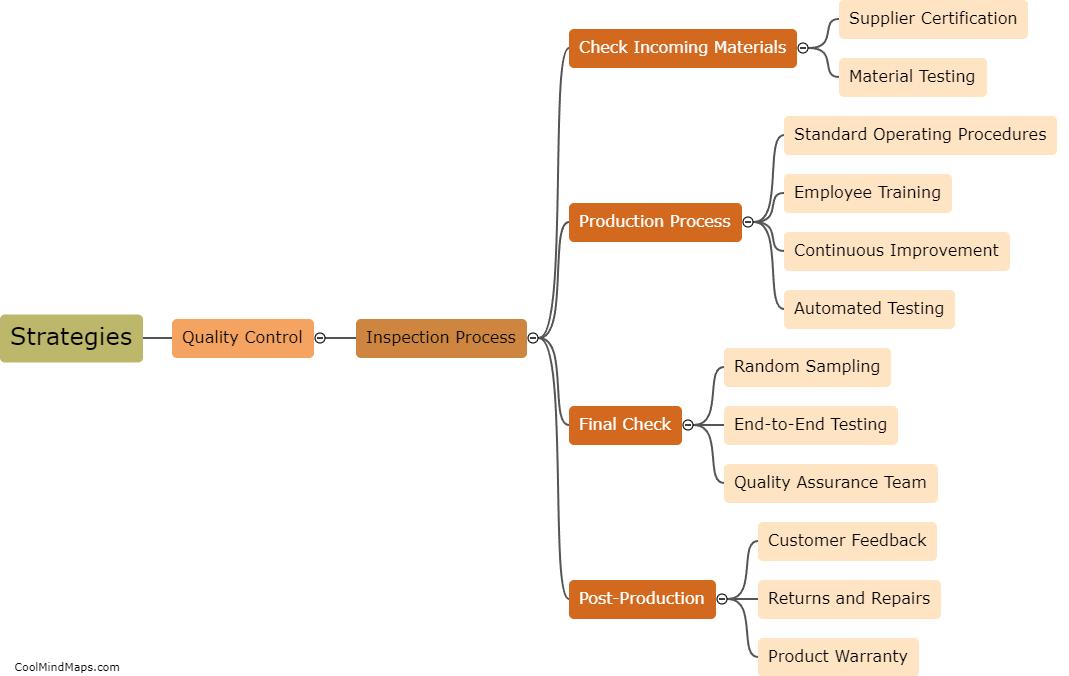

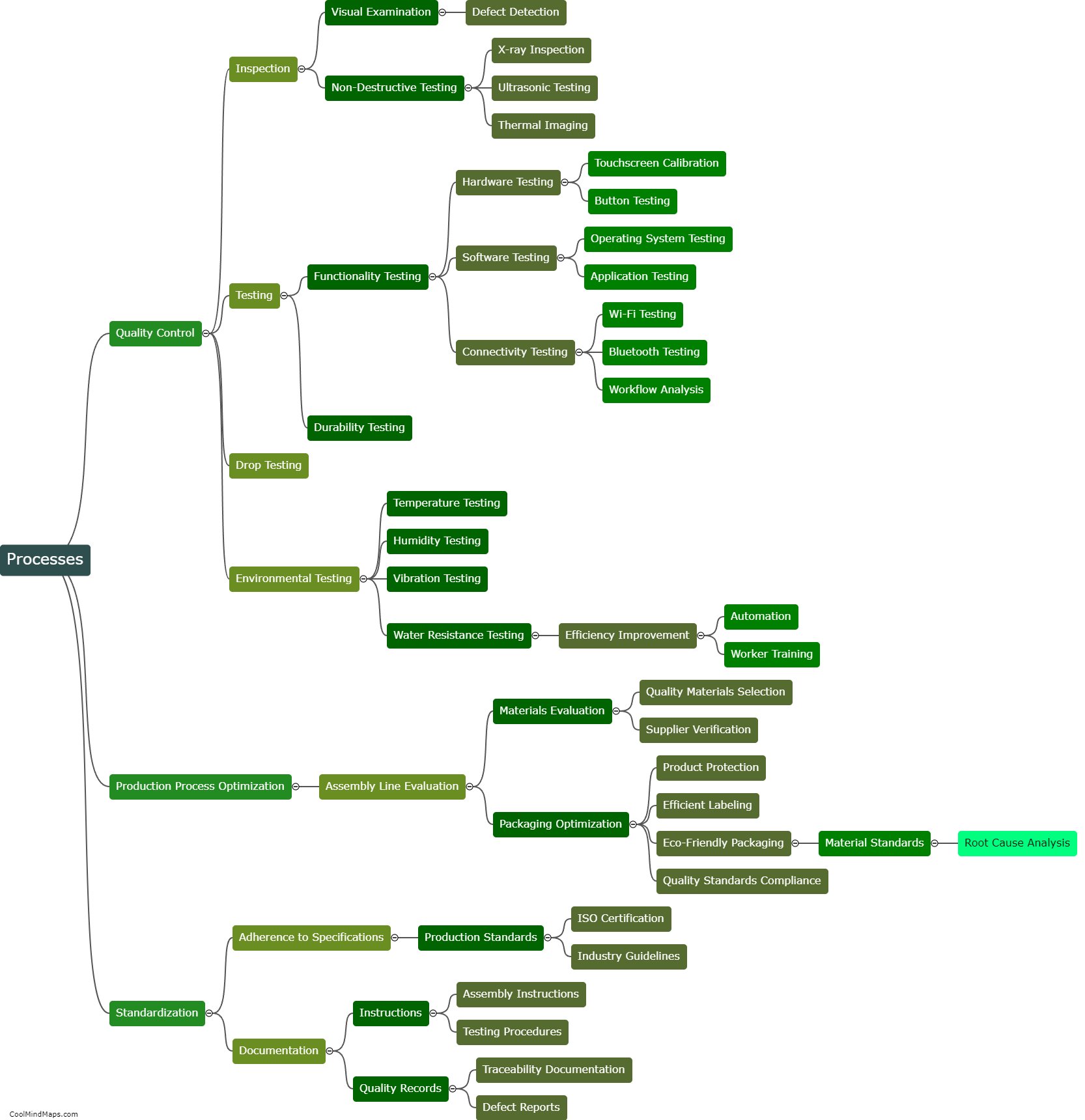

Maintaining quality in smartphone manufacturing is a complex task that involves several challenges. First and foremost, the rapidly evolving technology and fierce competition in the smartphone industry demand continuous innovation and the integration of advanced features. This puts pressure on manufacturers to accelerate the production process, leading to potential compromises in quality control. Moreover, the smaller and more intricate components used in smartphones require precise assembly, increasing the risk of defects or issues during manufacturing. Additionally, ensuring consistency in performance, reliability, and durability across millions of units is a significant challenge. Finally, maintaining quality throughout the global supply chain, with multiple suppliers and manufacturing facilities involved, further adds complexity to the process. Overcoming these challenges demands strong quality management systems, reliable testing procedures, and close collaborations between manufacturers and their suppliers.

This mind map was published on 10 November 2023 and has been viewed 76 times.