How is annealing used to enhance aircraft material properties?

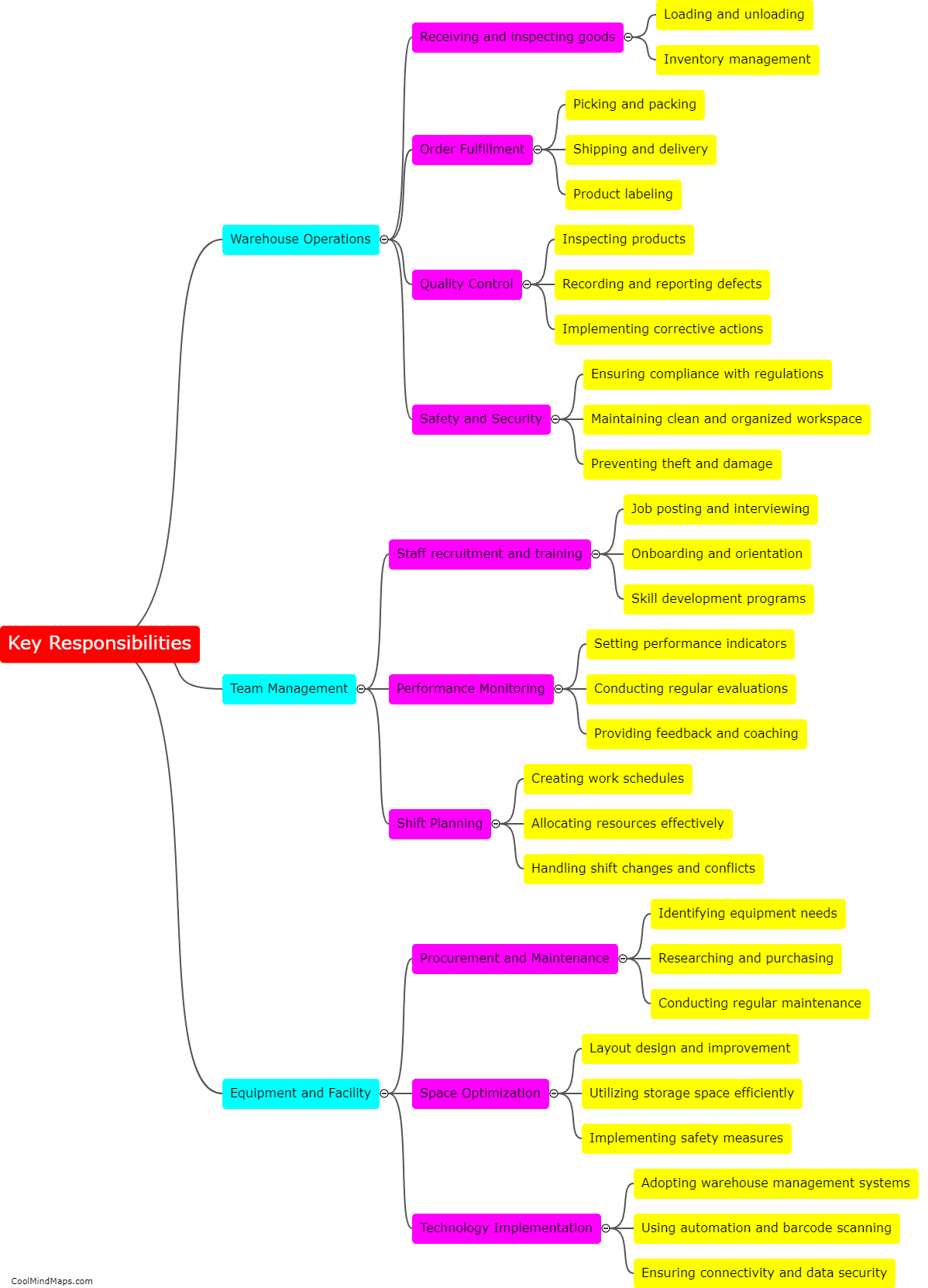

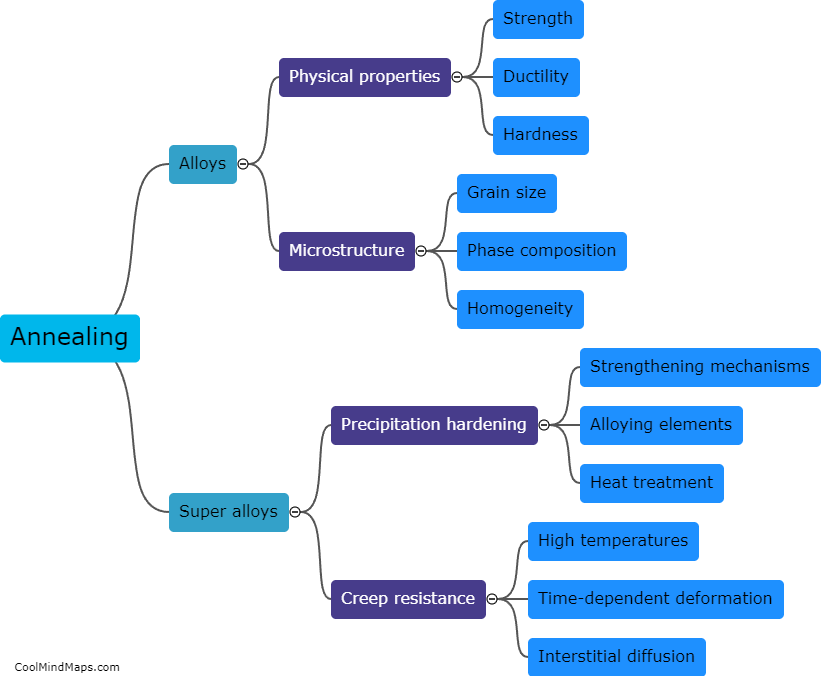

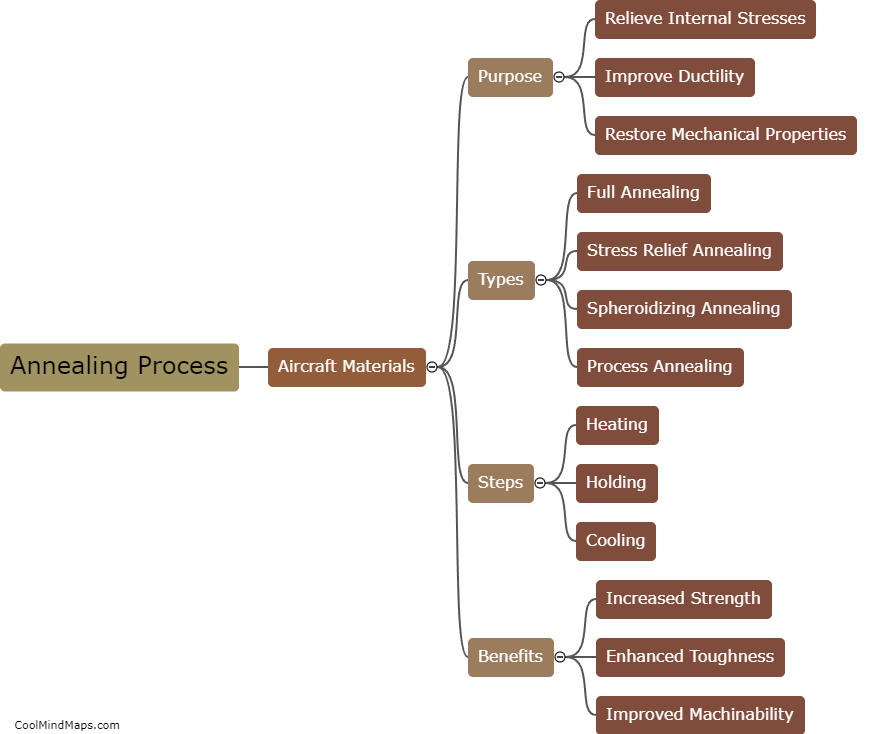

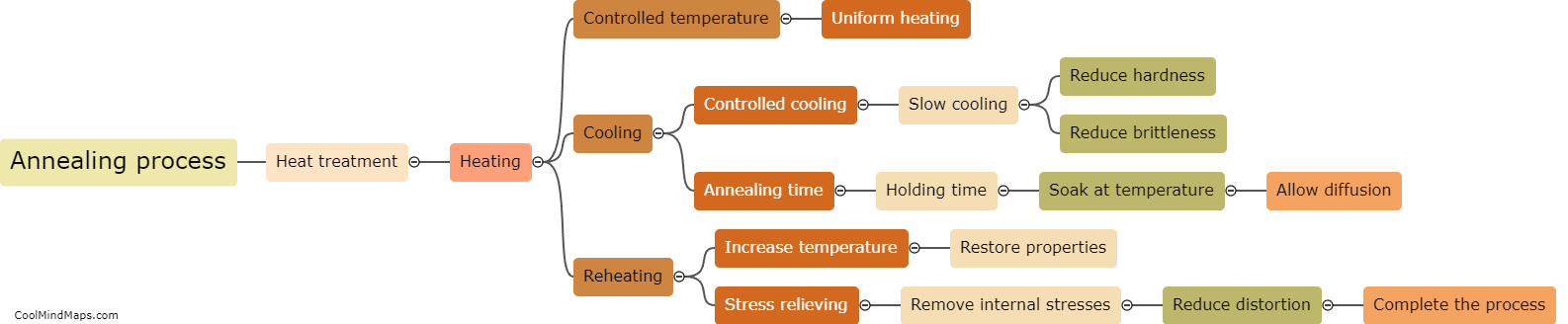

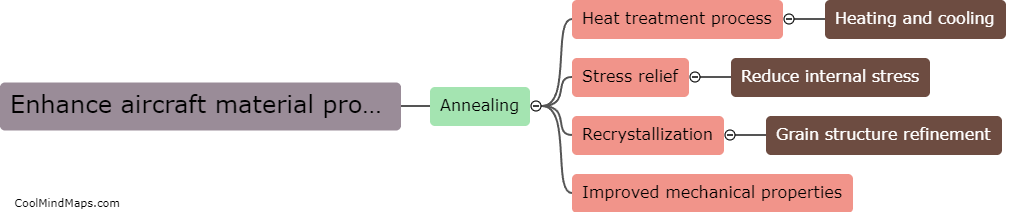

Annealing is a heat treatment process that is commonly used to enhance the material properties of aircraft components. During this process, the aircraft material, usually metals like aluminum or titanium, is heated to a specific temperature and then cooled slowly. This controlled heating and cooling cycle helps to eliminate internal stresses and improve the material's mechanical properties. Annealing also facilitates the development of a fine and homogeneous microstructure, which enhances the material's strength, ductility, and toughness. By undergoing annealing, aircraft materials can achieve improved structural integrity, increased resistance to fatigue and corrosion, and better overall performance in demanding operating conditions. Therefore, annealing plays a crucial role in optimizing the quality and reliability of aircraft materials, ensuring their suitability for aerospace applications.

This mind map was published on 31 August 2023 and has been viewed 107 times.