What is the heat treatment process in aircraft material manufacturing?

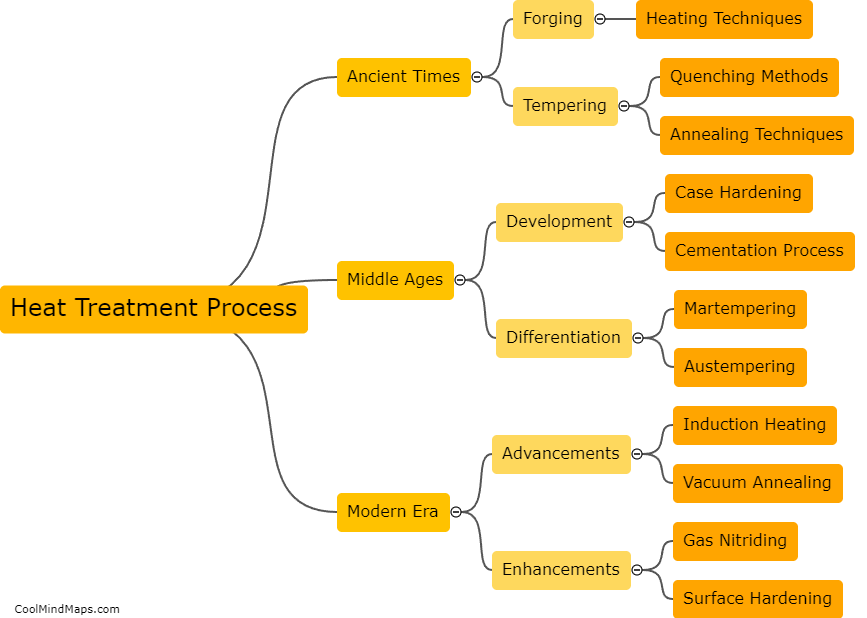

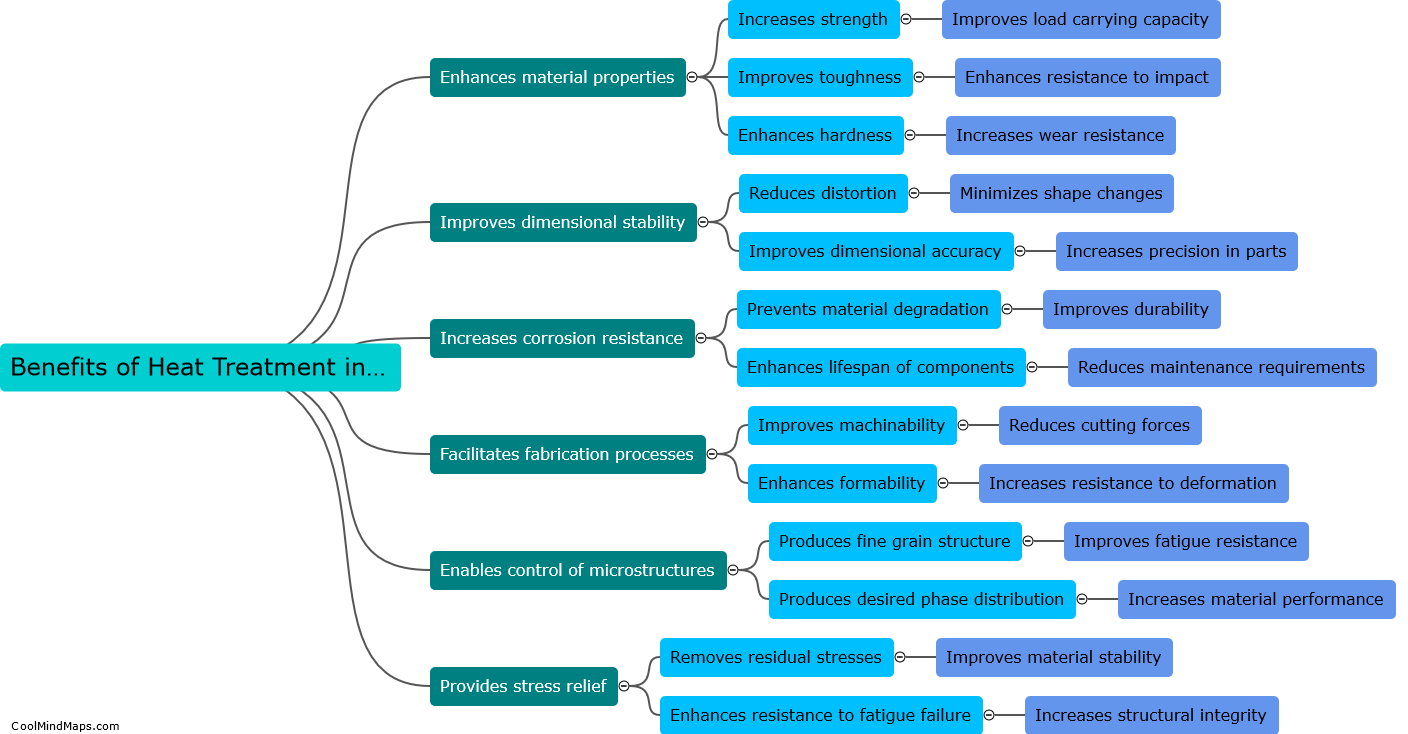

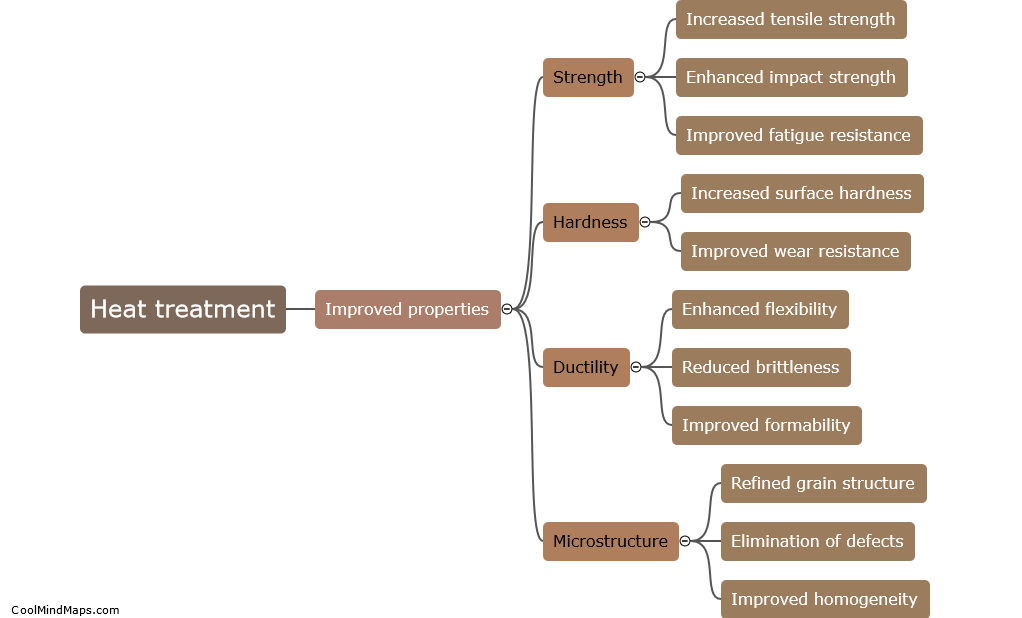

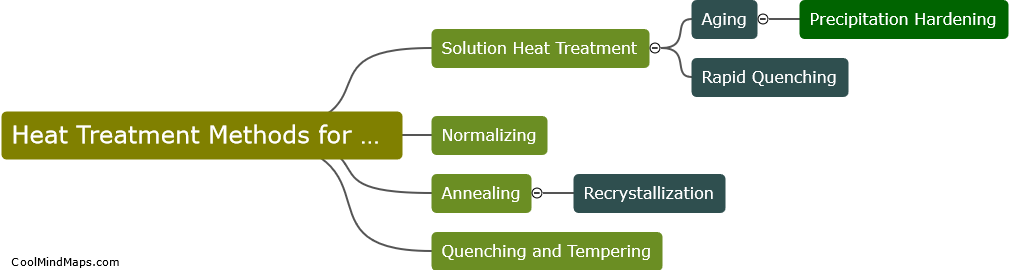

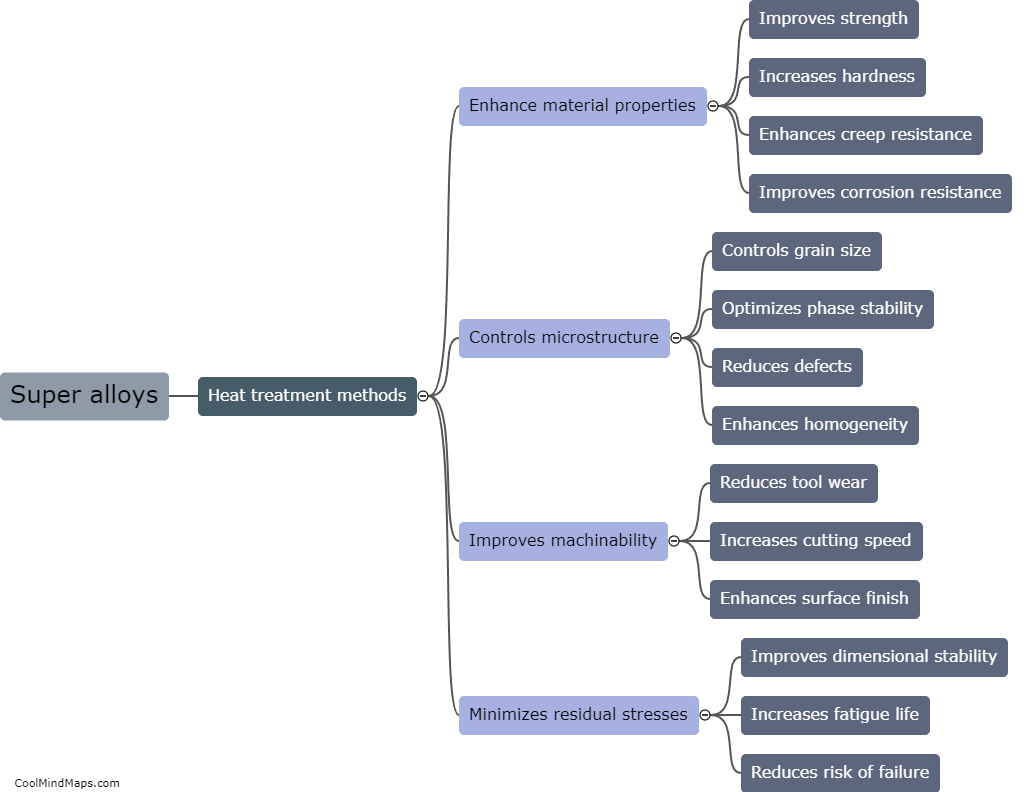

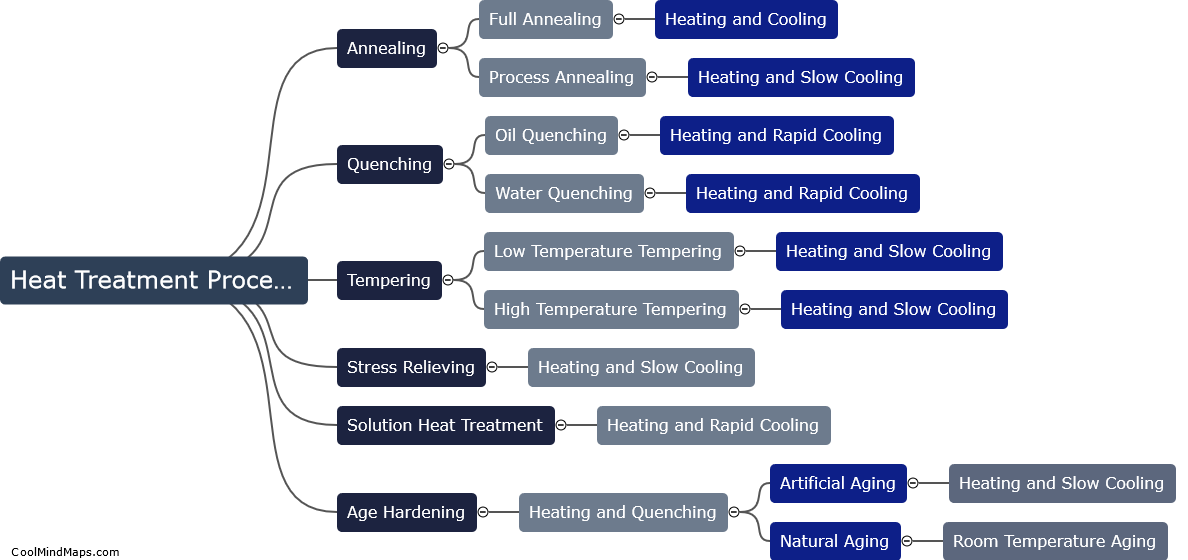

Heat treatment is a crucial process in aircraft material manufacturing that involves altering the physical and mechanical properties of materials to achieve desired characteristics. The process involves subjecting the materials, such as aluminum and steel alloys, to controlled heating and cooling cycles. Through specific temperature and time combinations, heat treatment can modify properties like hardness, strength, toughness, and corrosion resistance. This is achieved by changing the microstructure of the material, allowing for desired properties to be achieved. Heat treatment ensures that aircraft materials possess the necessary strength, durability, and performance capabilities required for safe and efficient operation in the demanding aerospace environment.

This mind map was published on 17 August 2023 and has been viewed 106 times.