How does heat treatment improve the properties of aircraft materials?

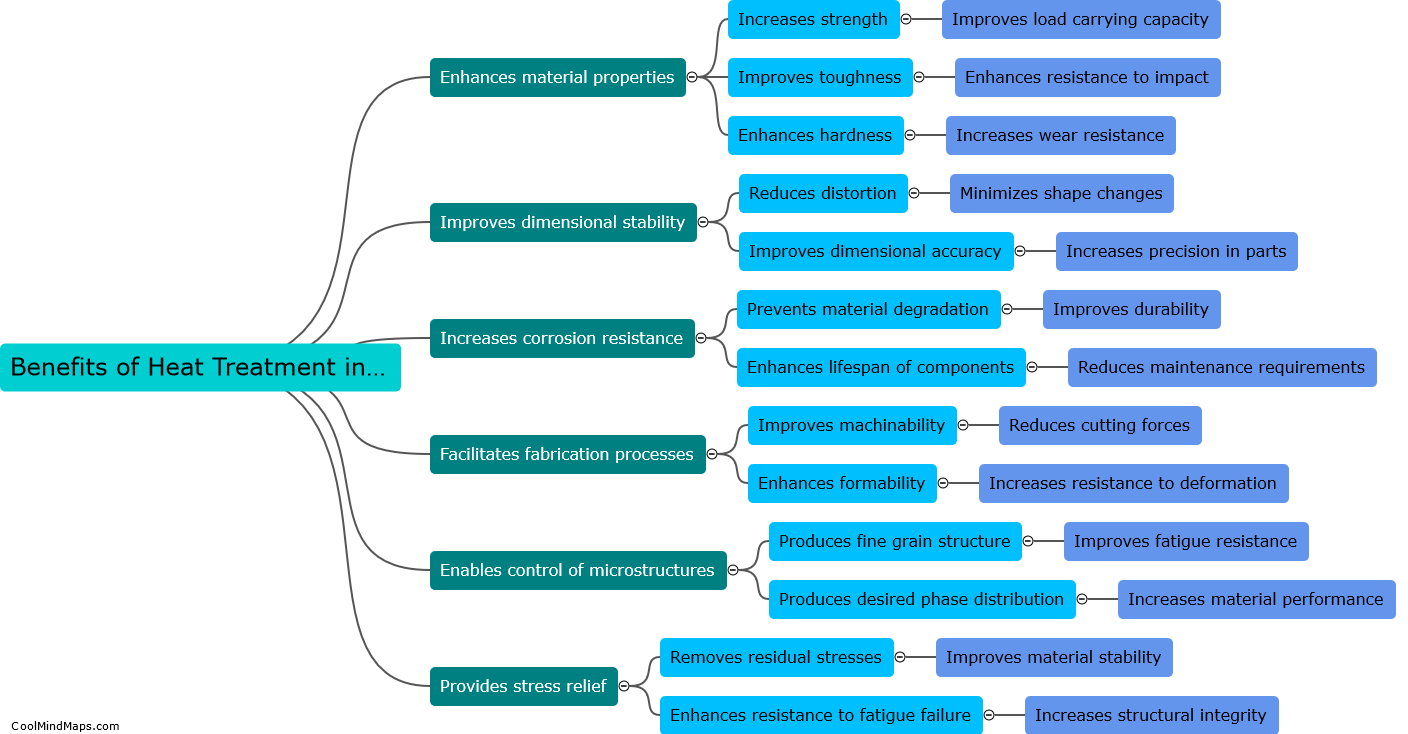

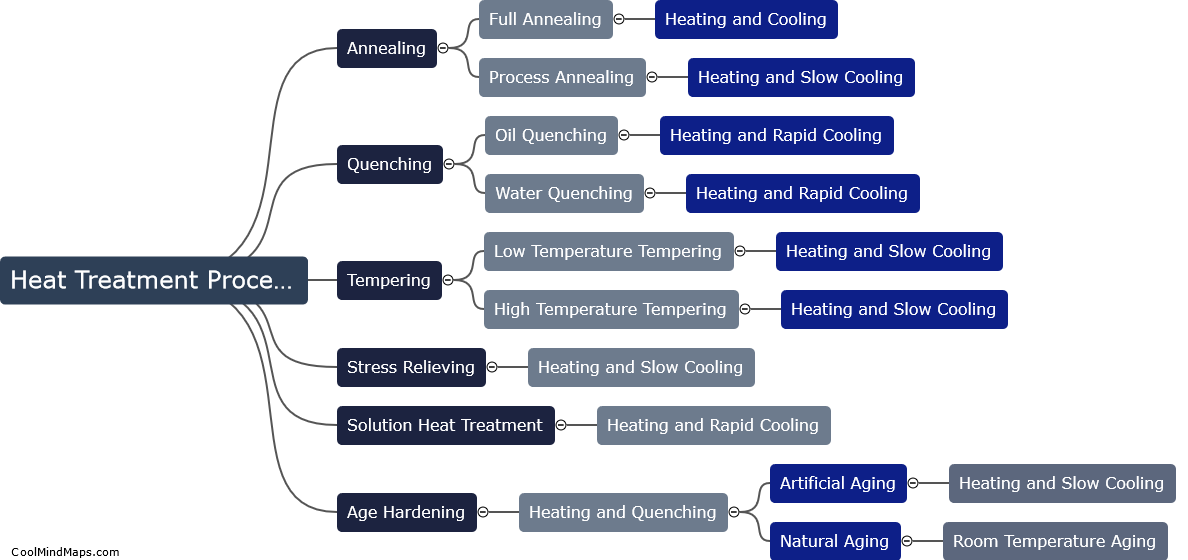

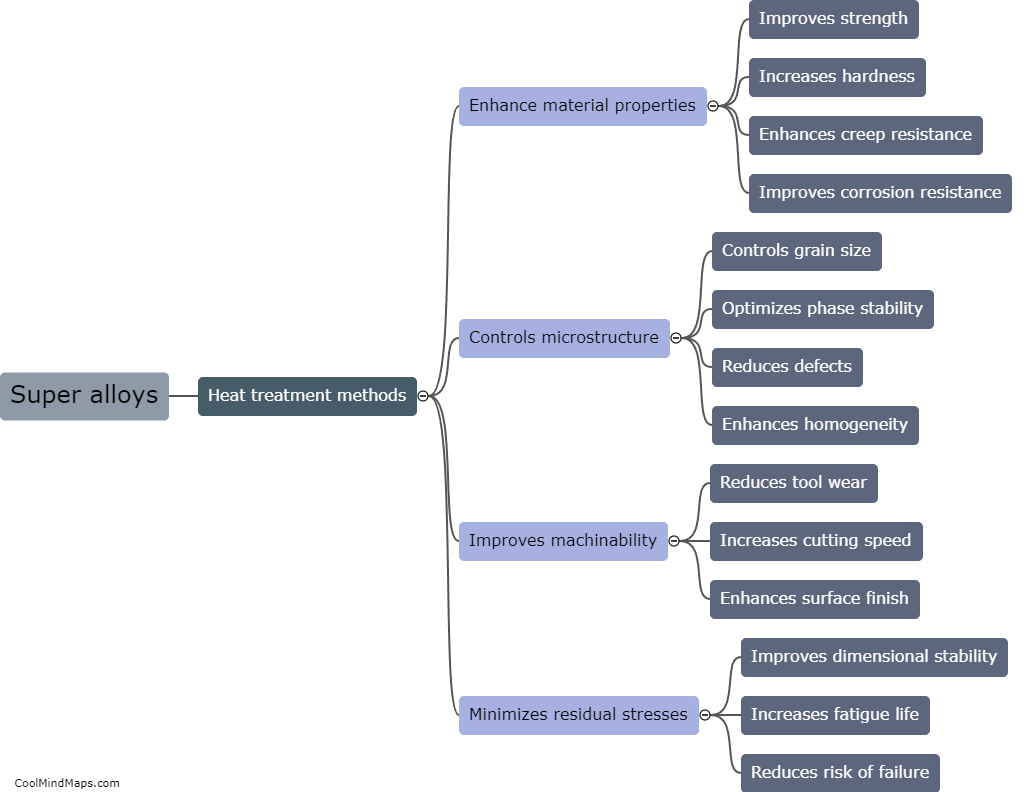

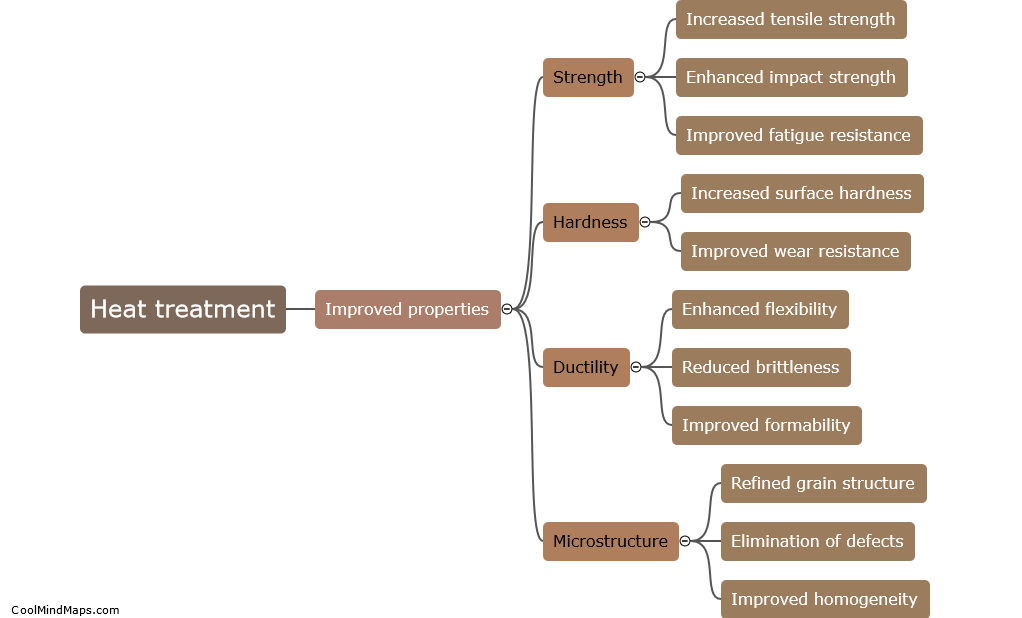

Heat treatment is a crucial process in enhancing the properties of aircraft materials. By subjecting the materials to controlled heating and cooling cycles, heat treatment can significantly improve their strength, hardness, ductility, and overall performance. The process involves heating the materials to specific temperatures and maintaining them at those levels for a certain duration, followed by controlled cooling. This controlled heating and cooling allow for the desired microstructure changes within the materials, resulting in improved mechanical properties. Heat treatment can also relieve internal stresses and improve the resistance to corrosion and fatigue, making aircraft materials more durable, reliable, and suitable for the demanding conditions of flight.

This mind map was published on 16 August 2023 and has been viewed 109 times.