What are the benefits of collaboration between QC, QA, PPC, Engineering, and Production?

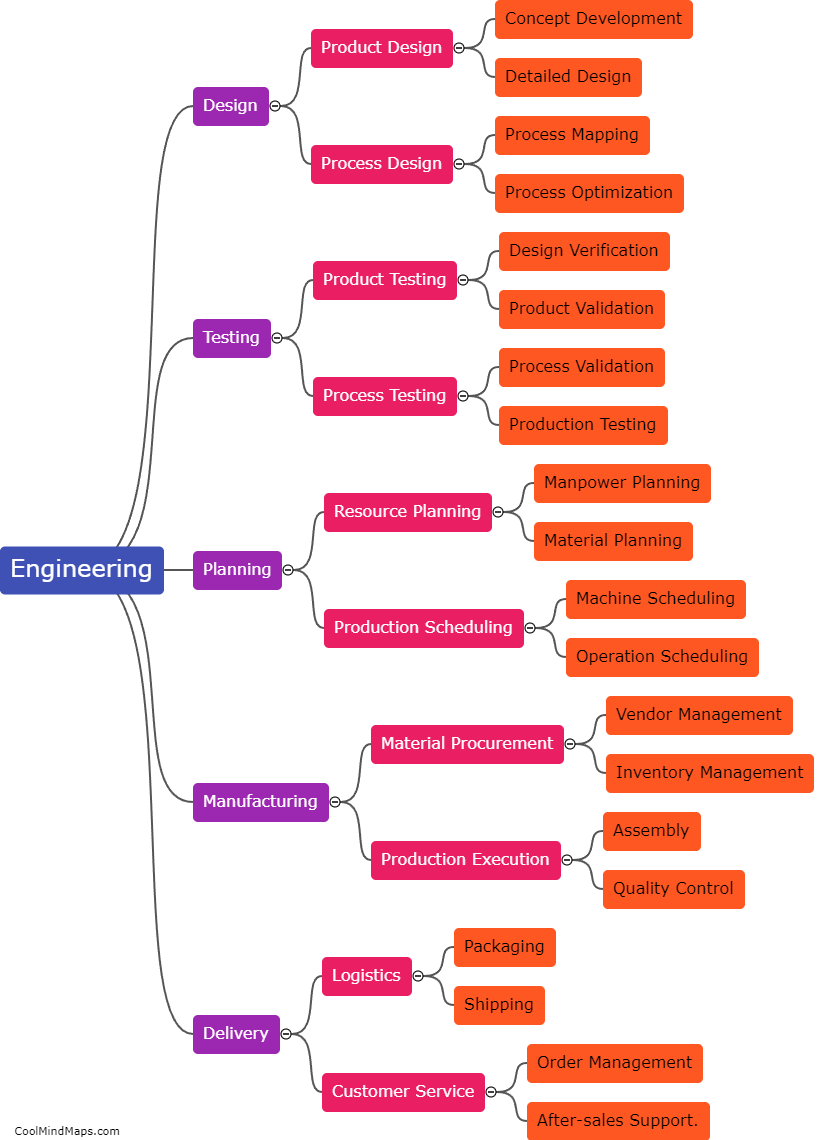

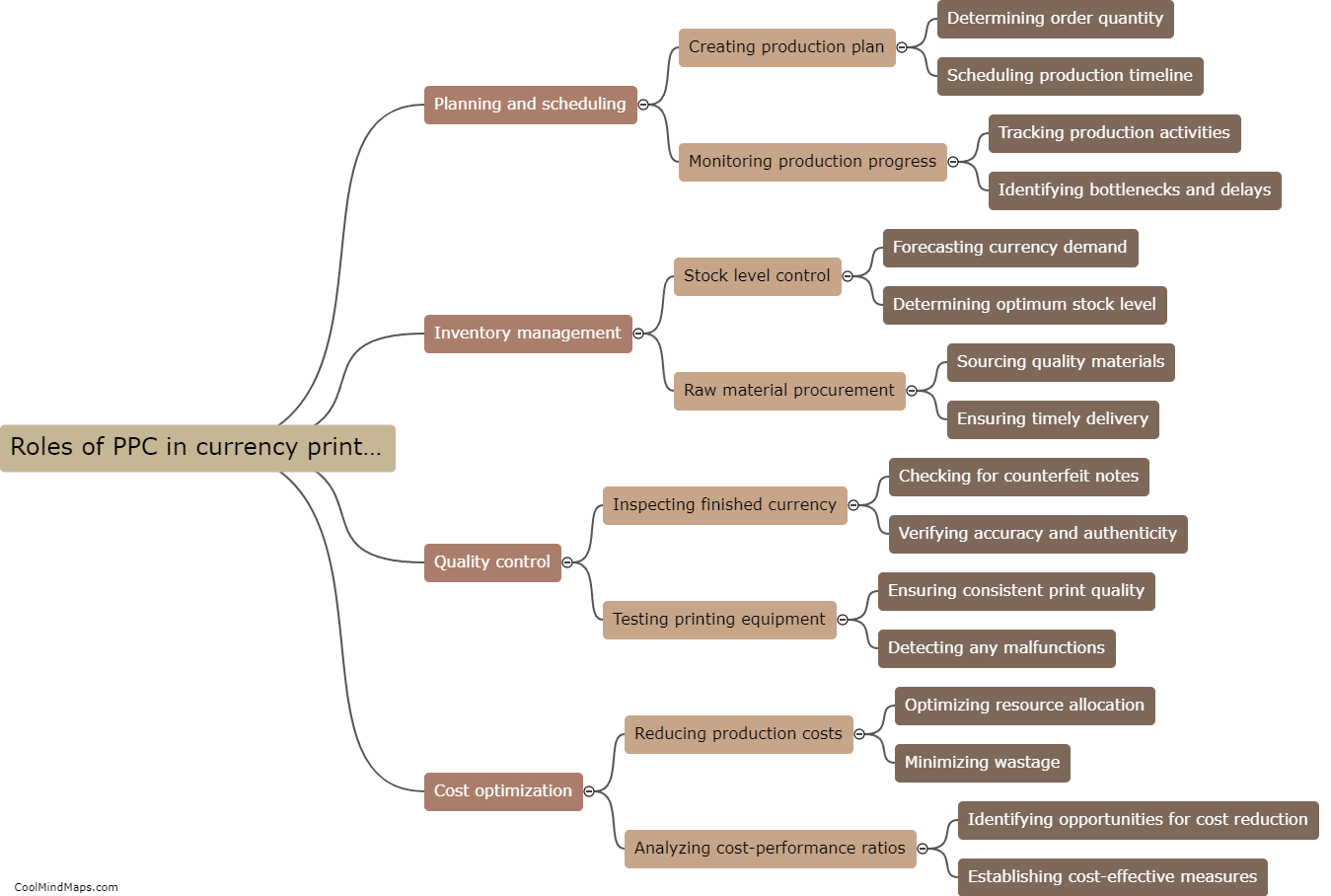

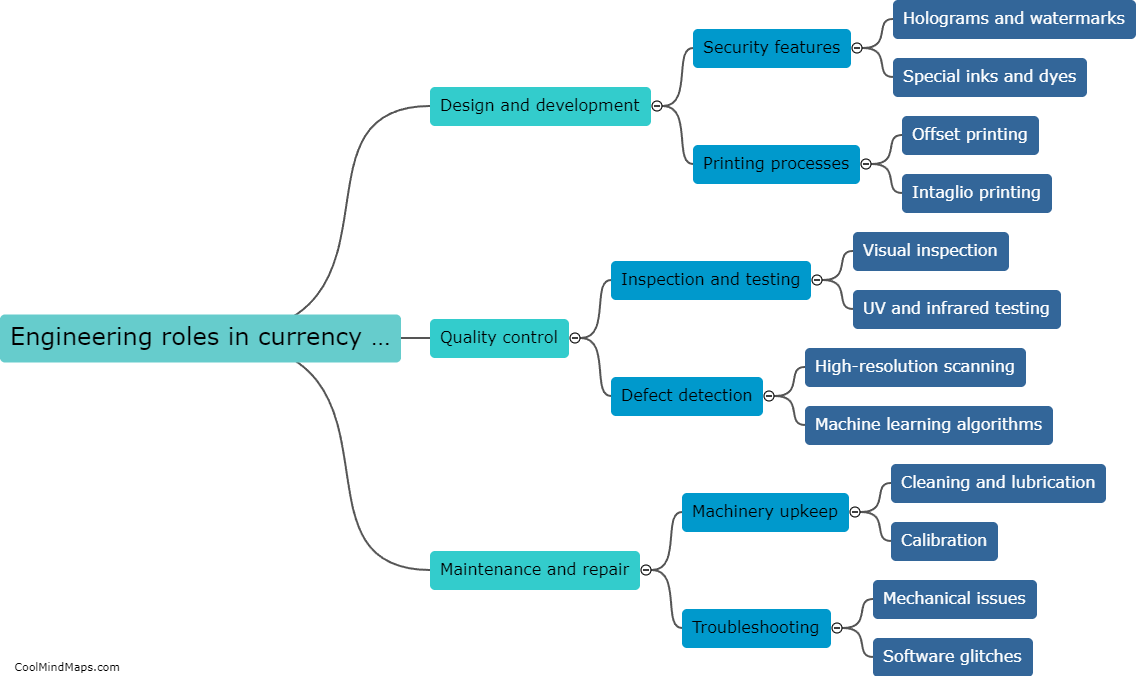

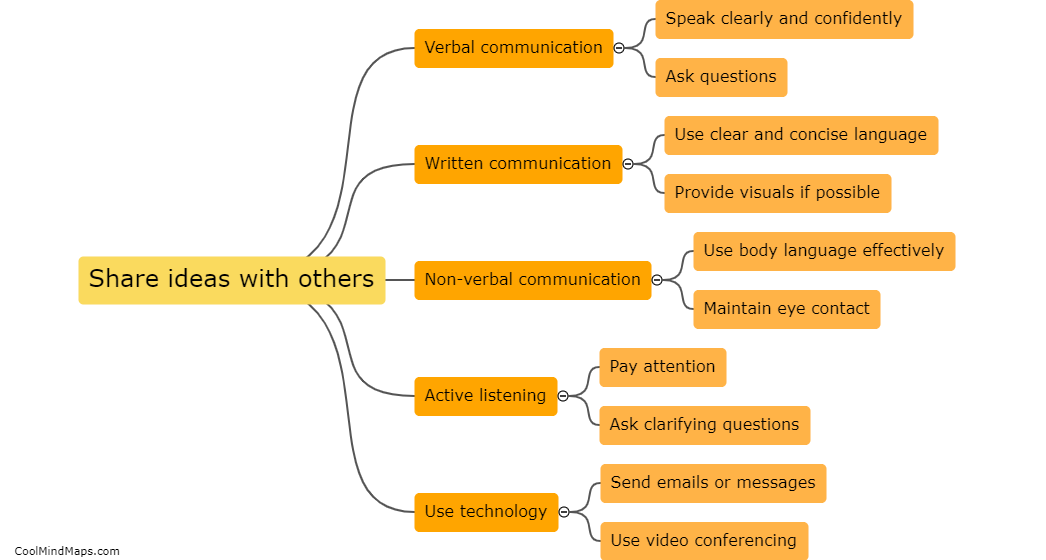

Collaboration between QC (Quality Control), QA (Quality Assurance), PPC (Production Planning and Control), Engineering, and Production brings numerous benefits to an organization. Firstly, it enhances overall product quality by fostering continuous improvement and identifying potential issues early on. Effective collaboration enables QC and QA to provide feedback to Engineering and Production, facilitating necessary modifications or improvements in product design and manufacturing processes. This eventually ensures that the final product meets or exceeds quality standards. Furthermore, close collaboration enhances efficiency and productivity as PPC can plan and control production based on the insights and recommendations provided by other departments. This helps in optimized resource allocation, reduced wastage, and improved manufacturing lead times. Overall, collaboration between these departments promotes a culture of teamwork, problem-solving, and innovation, leading to improved operational performance and customer satisfaction.

This mind map was published on 27 November 2023 and has been viewed 88 times.