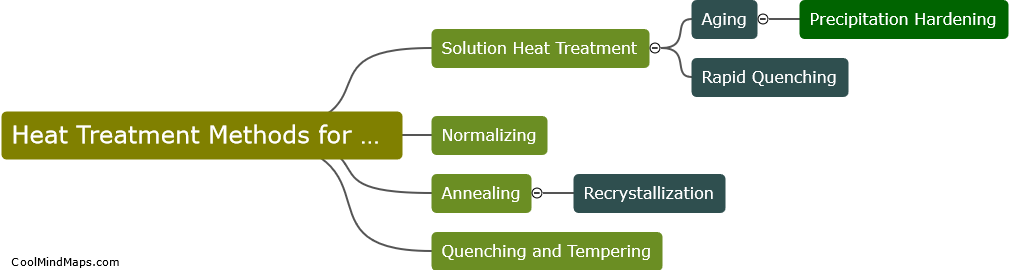

What are the different heat treatment methods for super alloys?

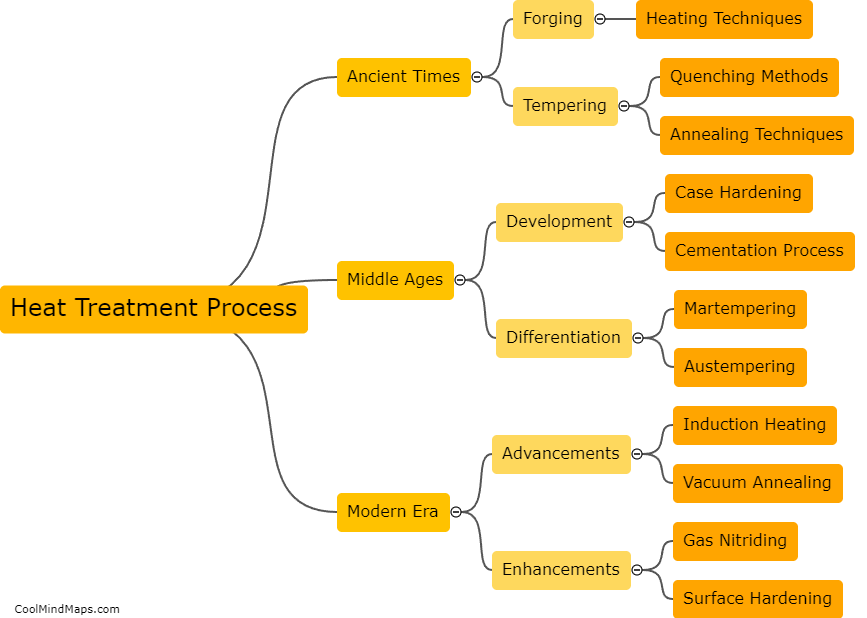

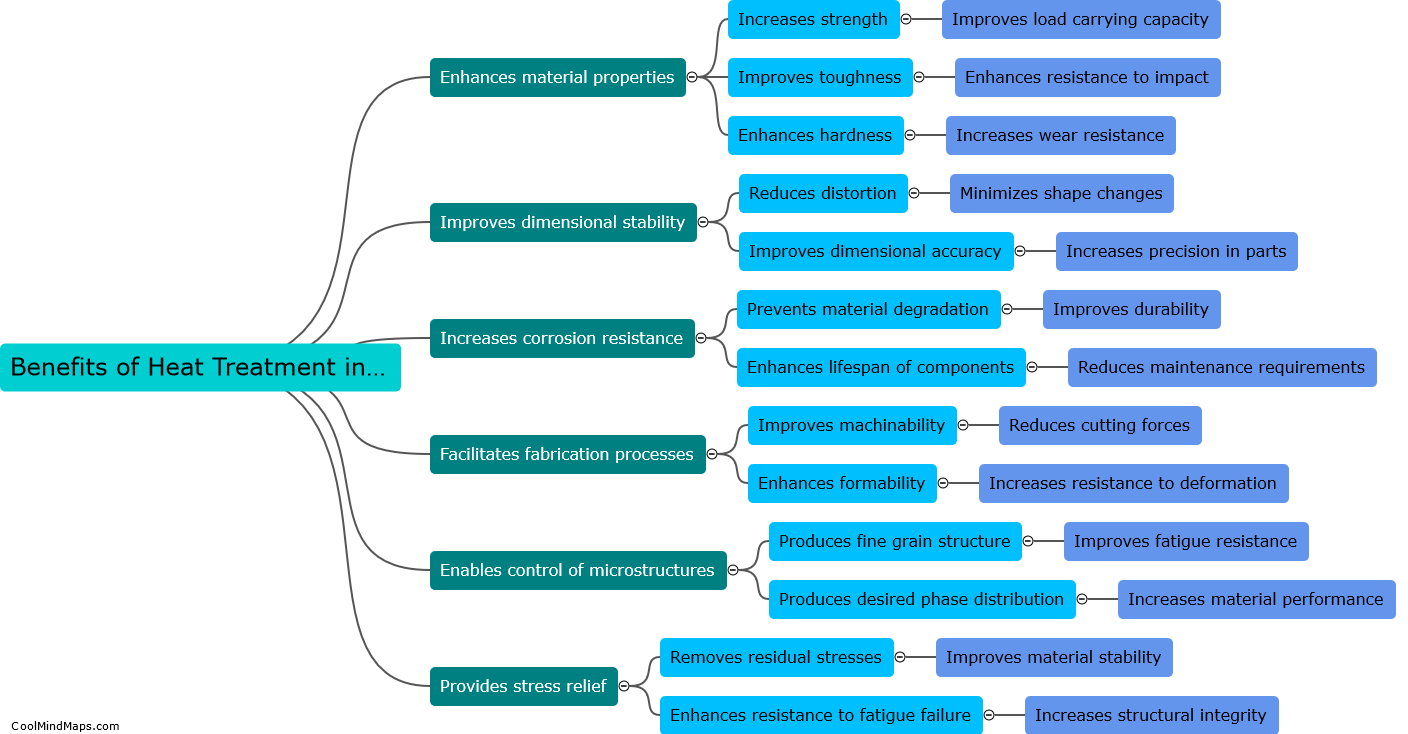

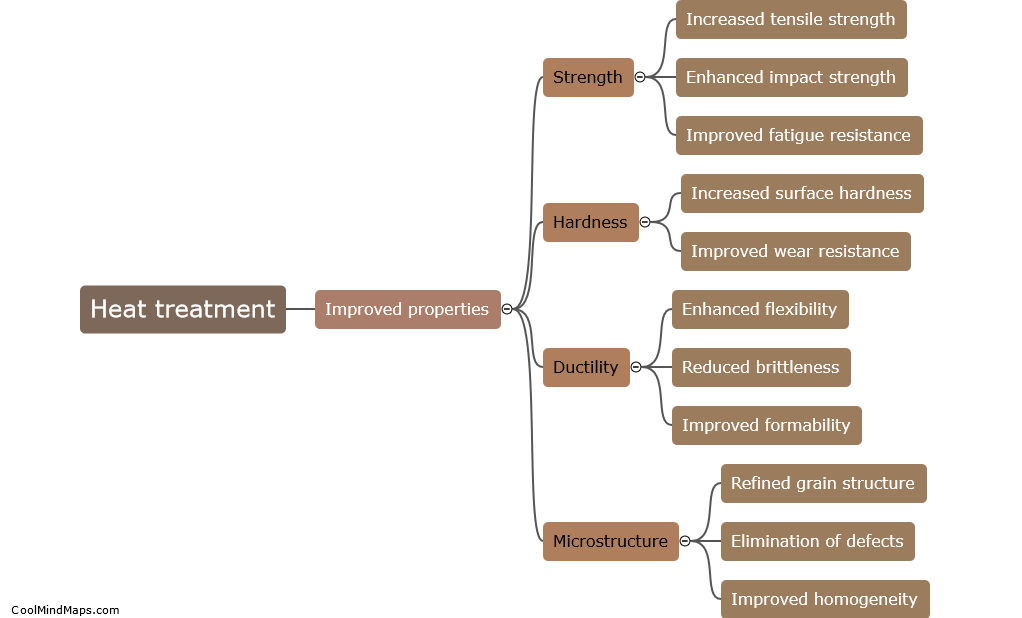

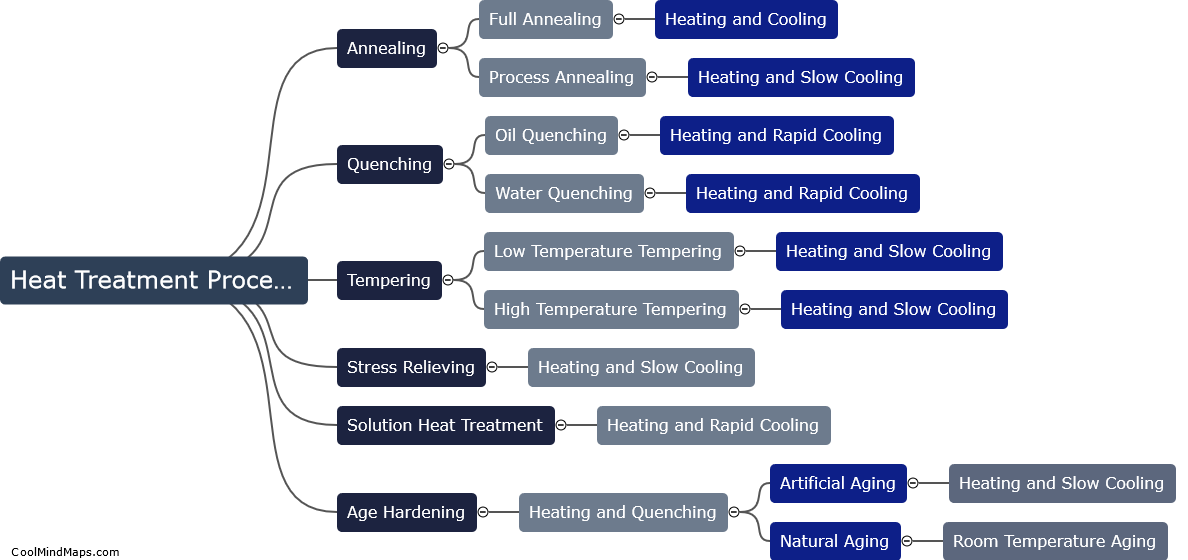

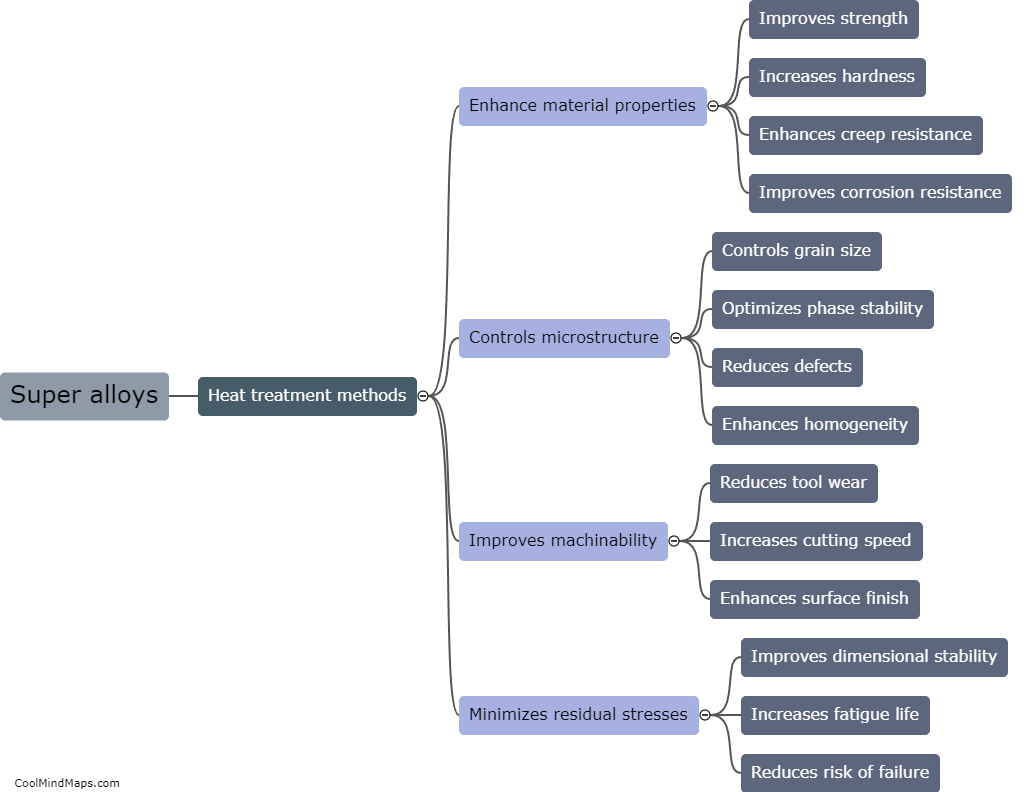

Super alloys are a group of high-performance materials known for their excellent resistance to extreme temperatures, corrosion, and stress. Heat treatment plays a crucial role in these alloys' performance and properties by optimizing their microstructure. There are several heat treatment methods used for super alloys, including solution treatment, aging, and stress relieving. Solution treatment involves heating the alloy to a high temperature, which dissolves any precipitates or impurities and helps homogenize the microstructure. Aging is then performed at a lower temperature to allow the formation and growth of desired precipitates, which further enhance the alloy's strength and stability. Stress relieving is a method used to eliminate residual stresses accumulated during manufacturing or processing. These different heat treatment methods enable super alloys to achieve their exceptional mechanical strength, resistance to creep, and stability at high temperatures, making them crucial materials in applications like aerospace, gas turbines, and nuclear reactors.

This mind map was published on 17 August 2023 and has been viewed 127 times.