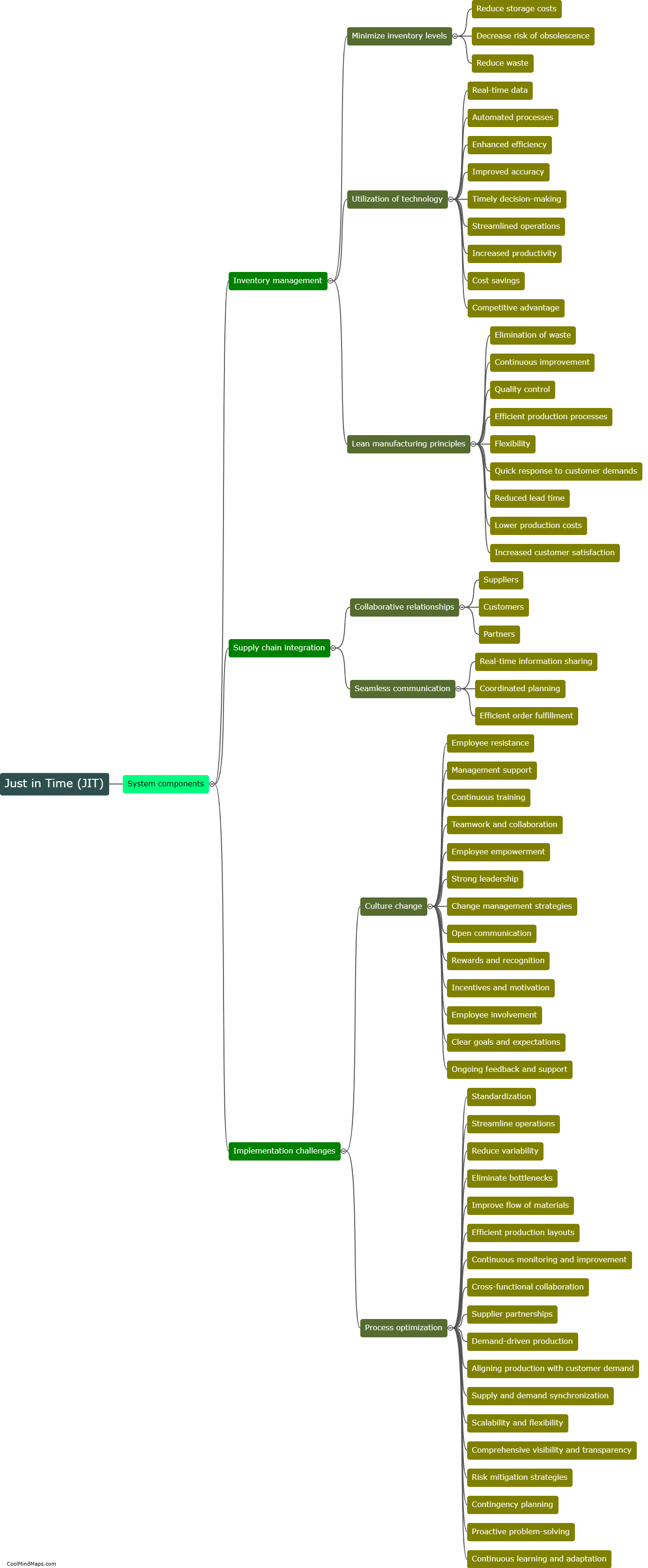

What is a Just in Time (JIT) system?

A Just-In-Time (JIT) system is an inventory management strategy that aims to minimize inventory levels by receiving and producing goods only as they are needed. In a JIT system, the focus is on reducing waste in the production process, including unnecessary inventory holding costs. The system relies heavily on accurate forecasting and coordination with suppliers to ensure that materials and components are delivered in a timely manner. By implementing a JIT system, companies can improve efficiency, reduce lead times, and increase productivity. However, it also requires a high level of coordination and collaboration between suppliers and manufacturers to ensure a seamless flow of materials and goods throughout the supply chain.

This mind map was published on 29 November 2023 and has been viewed 88 times.