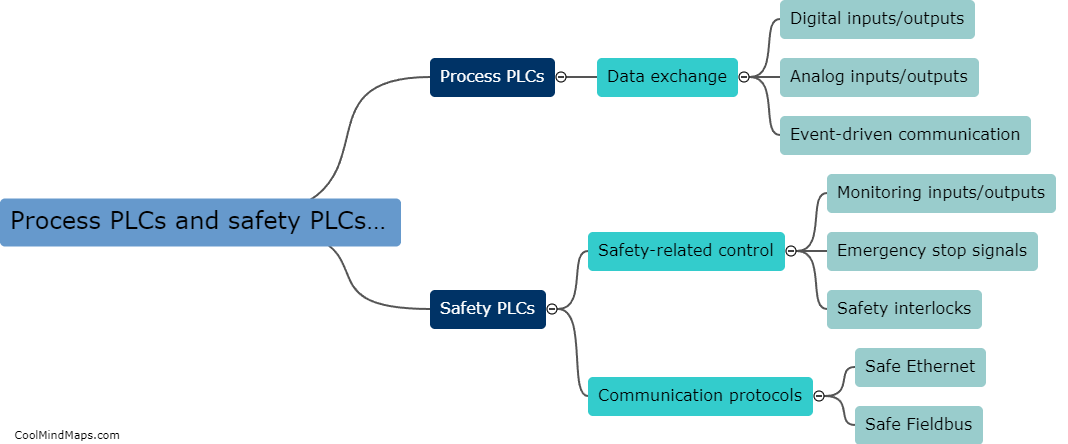

How do Process PLCs and safety PLCs communicate with TAS?

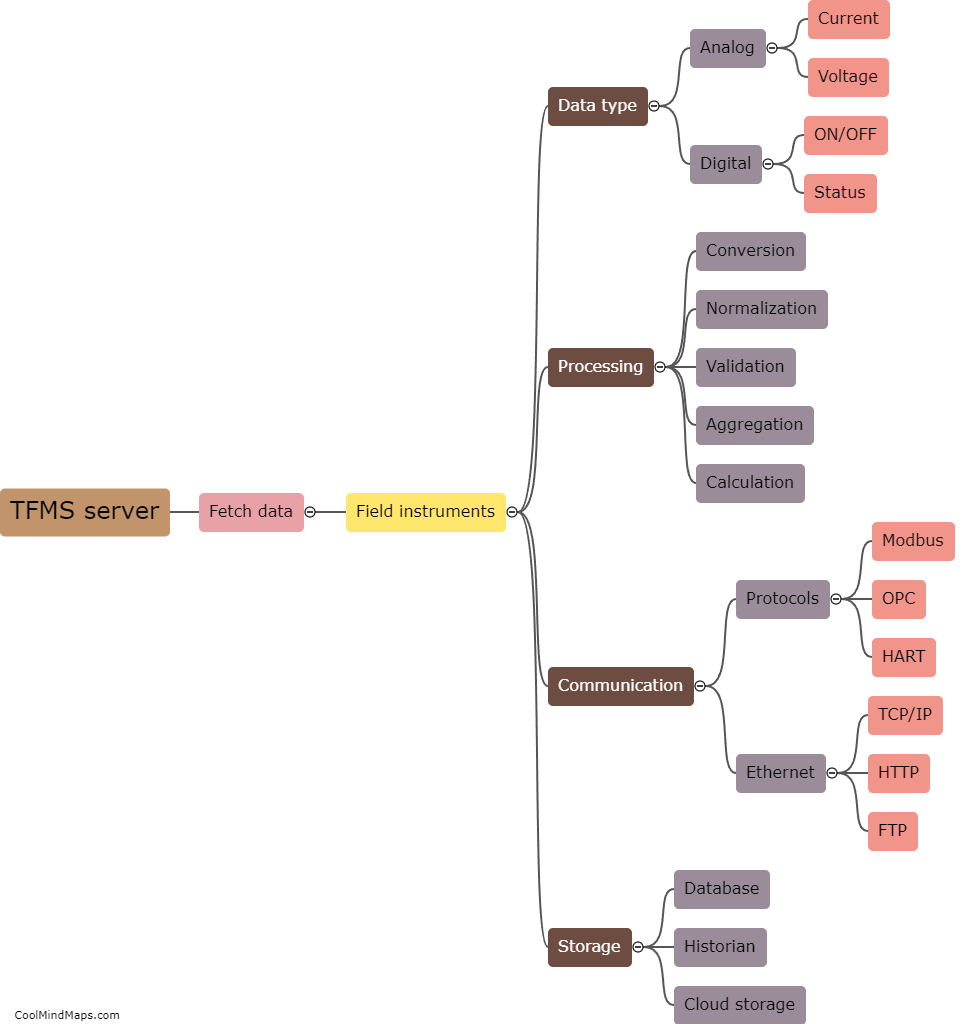

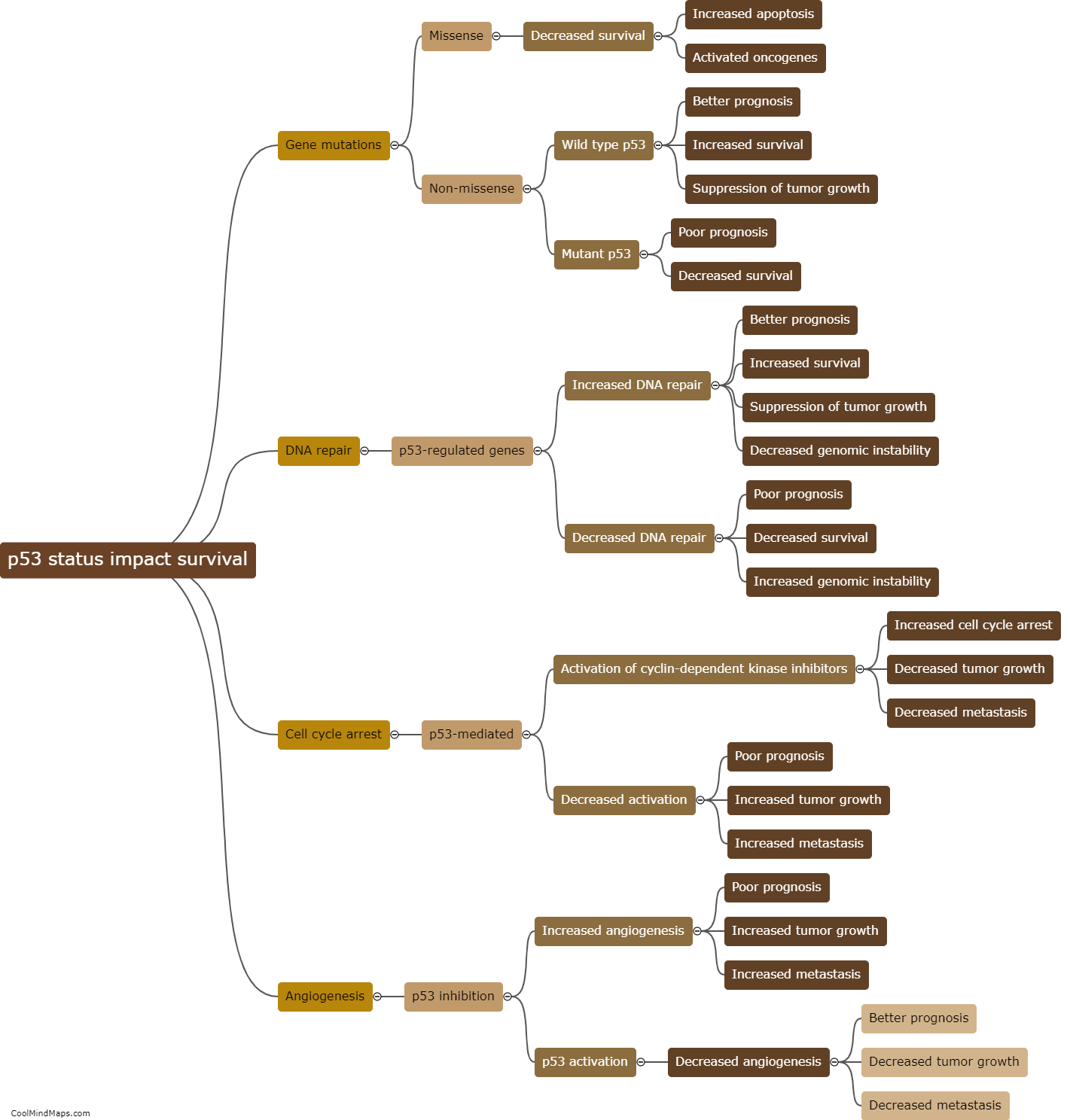

Process PLCs and safety PLCs communicate with TAS (Triconex Advanced Safety System) through various communication protocols and interfaces. TAS acts as a central control system for monitoring and managing critical processes in industries like oil and gas, power generation, and manufacturing. Process PLCs typically use standard communication protocols like Modbus, OPC (OLE for Process Control), or Ethernet/IP to exchange data with TAS. These protocols allow for seamless transfer of process variables such as temperature, pressure, or flow rate between the PLCs and TAS. On the other hand, safety PLCs use specialized safety communication protocols like TMR (Triple Modular Redundant) or DCS (Distributed Control System) to ensure reliable and fault-tolerant communication with TAS. These safety protocols prioritize safety-critical information, enabling rapid response and ensuring the integrity of safety systems. Overall, the communication between process PLCs, safety PLCs, and TAS plays a crucial role in maintaining safe and efficient operations within industrial environments.

This mind map was published on 17 October 2023 and has been viewed 96 times.