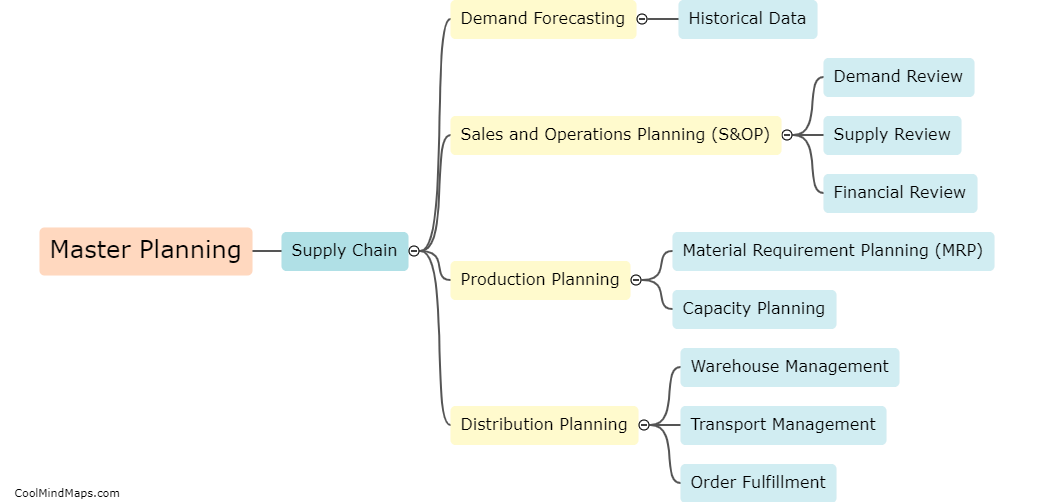

What are the key components of master planning in supply chain?

Master planning in supply chain involves the integration of various key components to effectively manage the flow of goods and services from suppliers to customers. The main components of master planning include demand forecasting, inventory management, production planning, and capacity planning. Demand forecasting helps in determining the expected demand for products, which forms the basis for all other planning activities. Inventory management aims to maintain optimum levels of inventory to meet customer demand while minimizing carrying costs. Production planning involves determining what, how much, and when to produce, taking into account capacity and resource constraints. Capacity planning focuses on ensuring that adequate resources and facilities are available to meet the planned production levels. These key components enable organizations to optimize their supply chain operations and enhance customer satisfaction.

This mind map was published on 16 November 2023 and has been viewed 113 times.