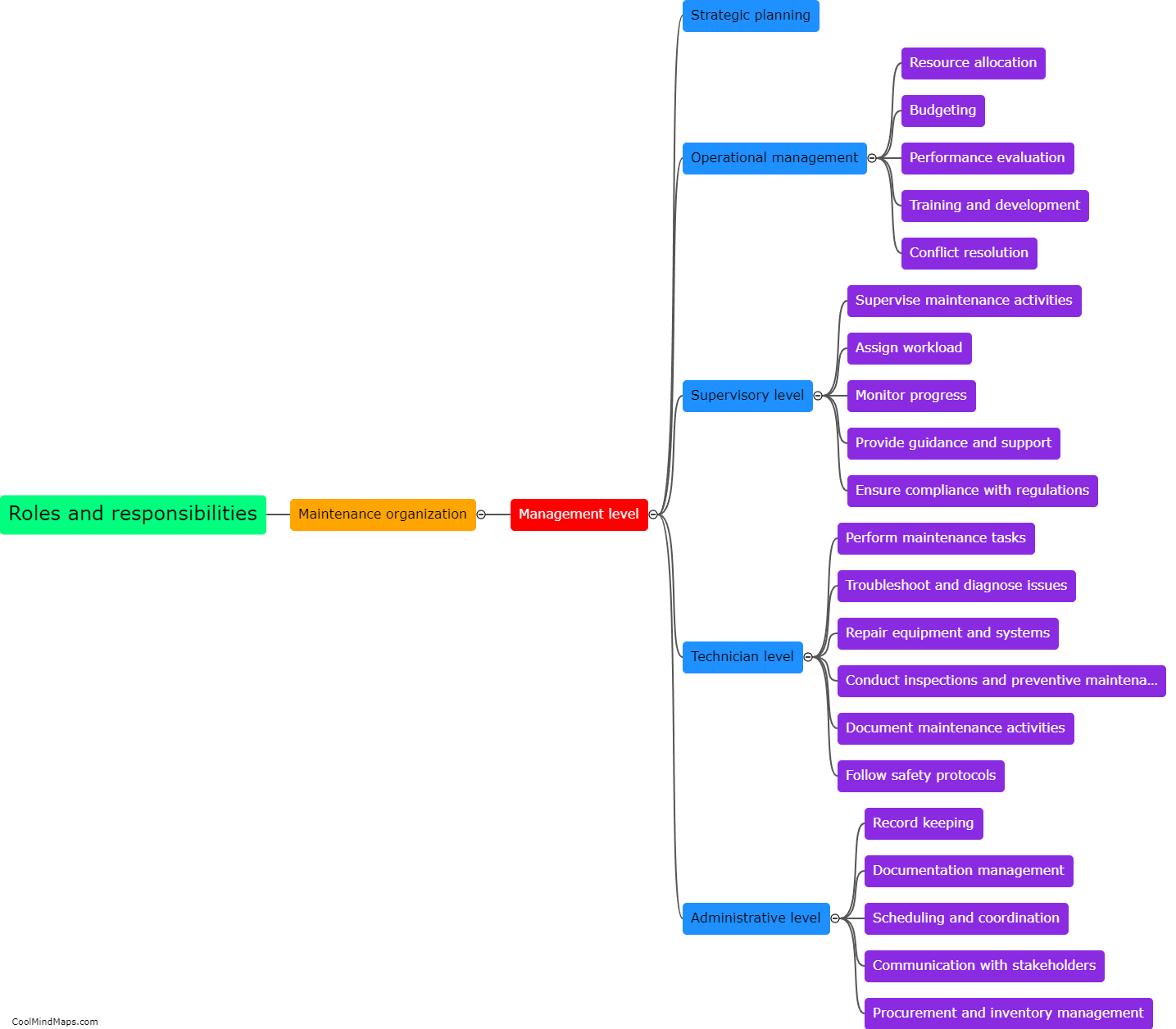

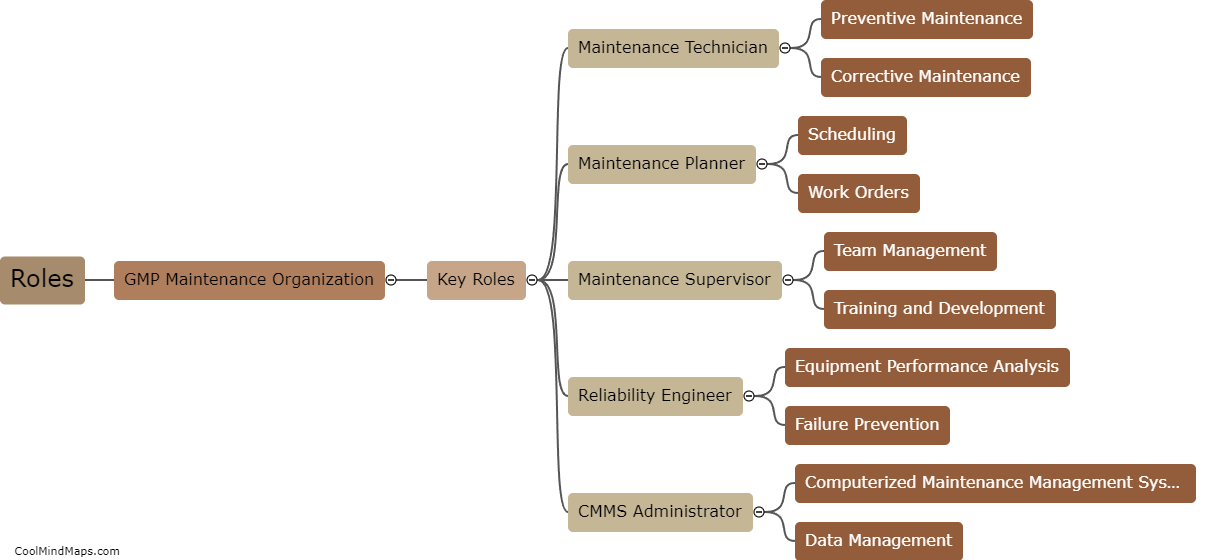

What are the key roles in a GMP maintenance organization?

In a GMP (Good Manufacturing Practice) maintenance organization, there are several key roles that play crucial functions in ensuring the smooth operation and compliance of manufacturing processes. The Maintenance Manager oversees all aspects of the maintenance department, including planning, scheduling, and executing activities, as well as managing the maintenance staff. The Maintenance Engineer is responsible for troubleshooting and resolving complex technical issues, conducting equipment validations, and implementing preventive maintenance programs. The Technician carries out routine maintenance tasks, conducts equipment inspections, and performs repairs when necessary. The Calibration Specialist ensures the accuracy and reliability of measurement instruments and equipment through regular calibration and validation. Finally, the Documentation Specialist ensures that all maintenance activities comply with GMP regulations by maintaining accurate records and updating necessary documentation. These roles work together to ensure that manufacturing equipment is well-maintained, functional, and compliant with GMP standards.

This mind map was published on 27 November 2023 and has been viewed 85 times.