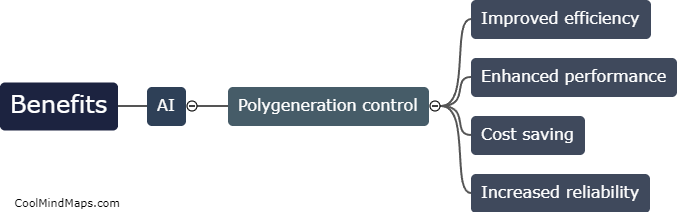

What are the benefits of implementing IoT in rice milling factories?

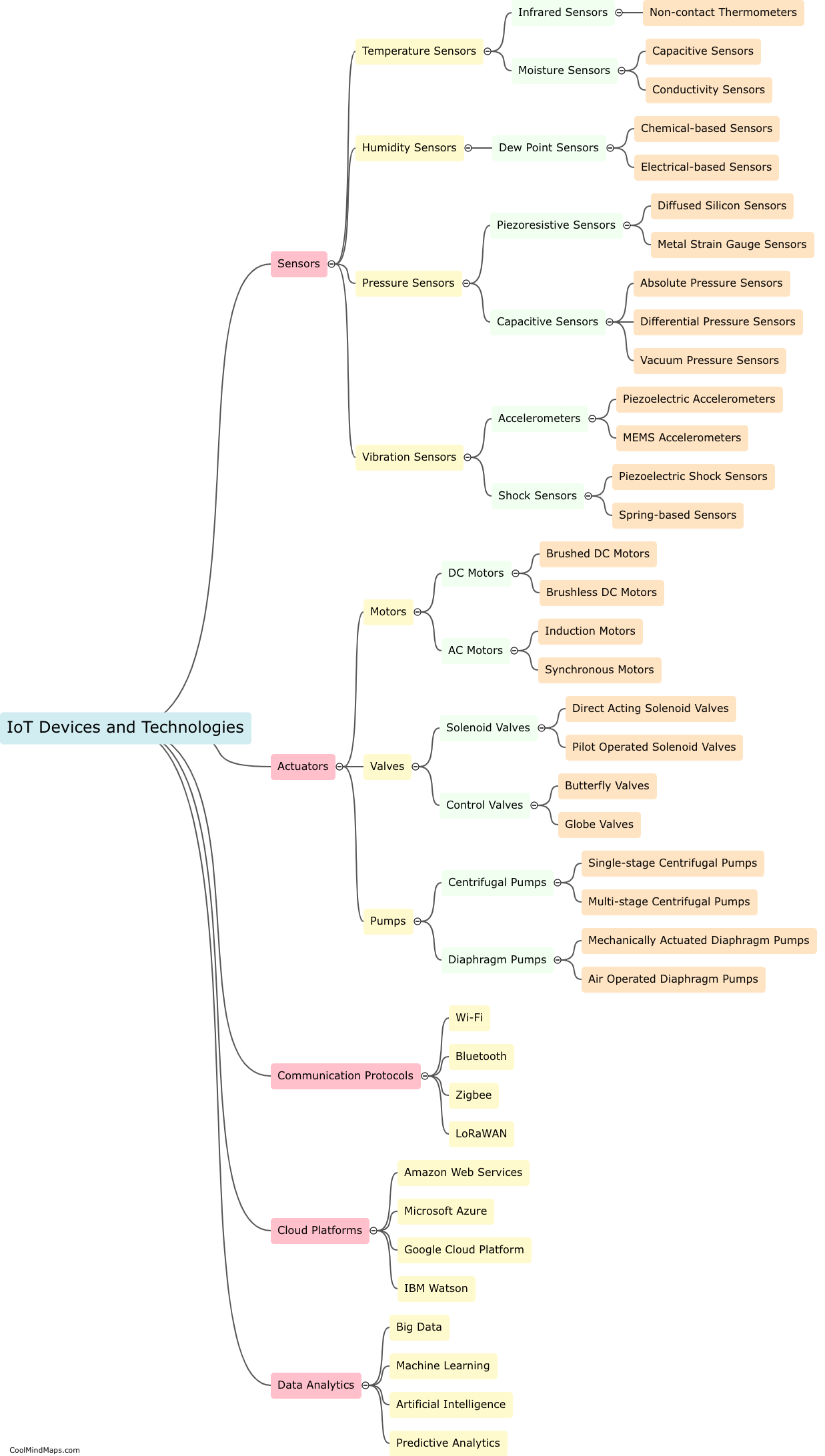

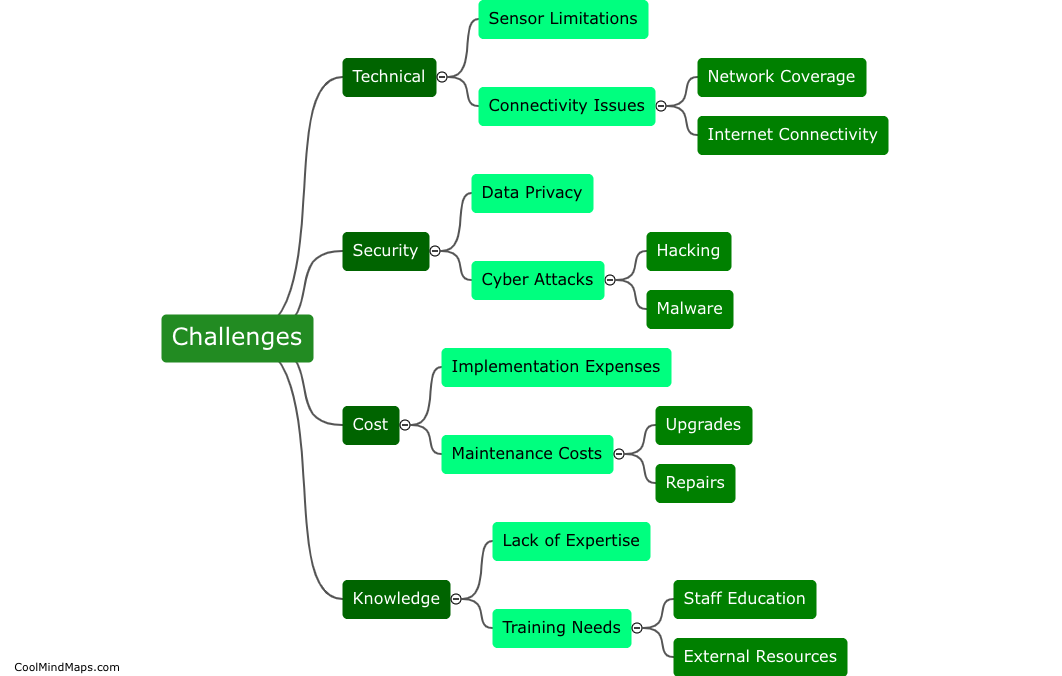

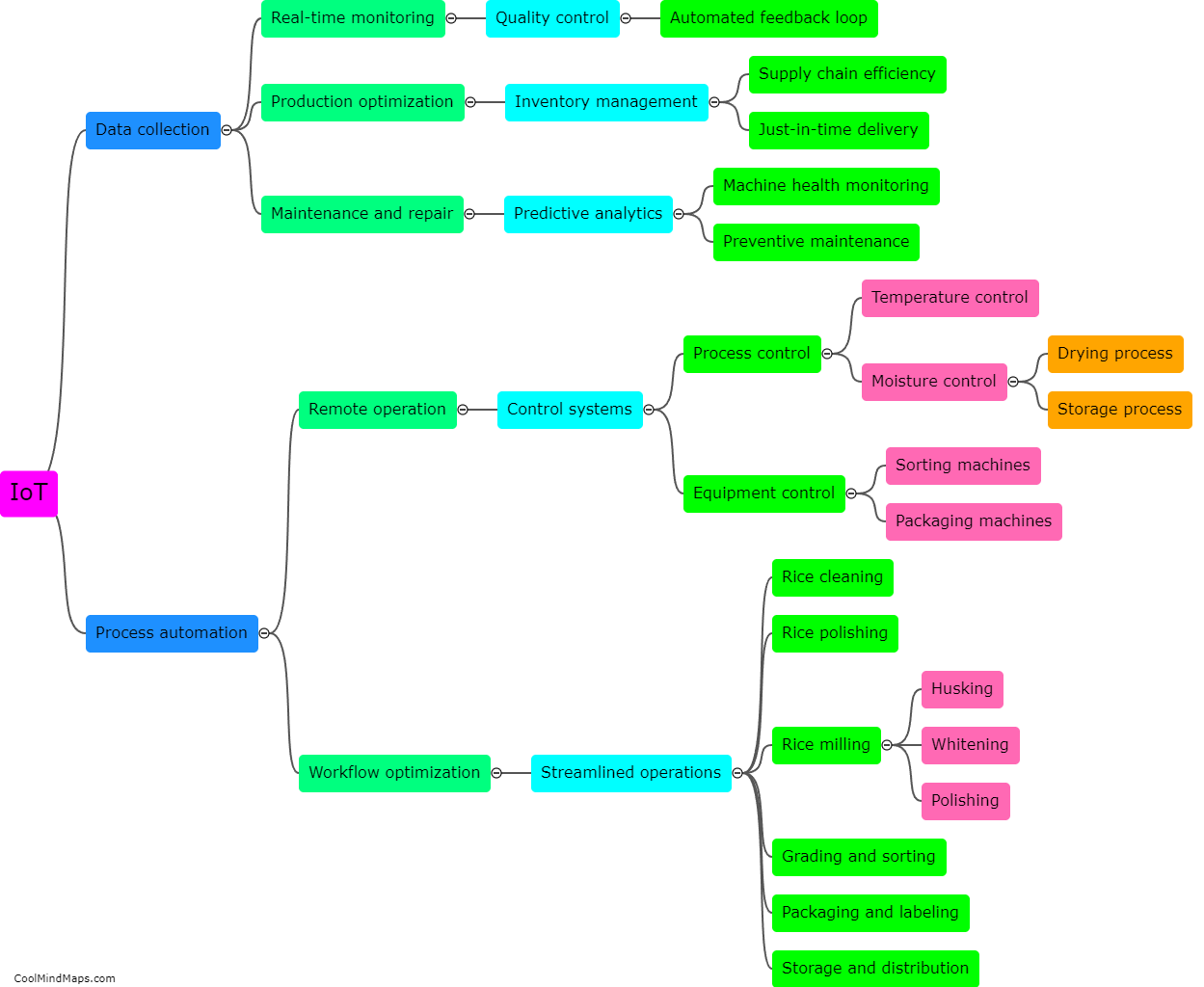

Implementing IoT (Internet of Things) in rice milling factories offers numerous benefits. First and foremost, it enhances operational efficiency by automating various aspects of the manufacturing process. IoT-enabled sensors can collect real-time data on temperature, humidity, and moisture levels, ensuring optimal storage conditions for the rice grains. This helps prevent quality deterioration and reduces wastage. Additionally, IoT devices can monitor and control the milling equipment to ensure proper functioning, minimizing downtime and maintenance costs. Improved inventory management is another advantage, as IoT systems can track the quantity and quality of rice in real-time, enabling better planning and reducing inventory holding costs. Overall, the implementation of IoT technology in rice milling factories improves productivity, reduces costs, and enhances the quality of the final product.

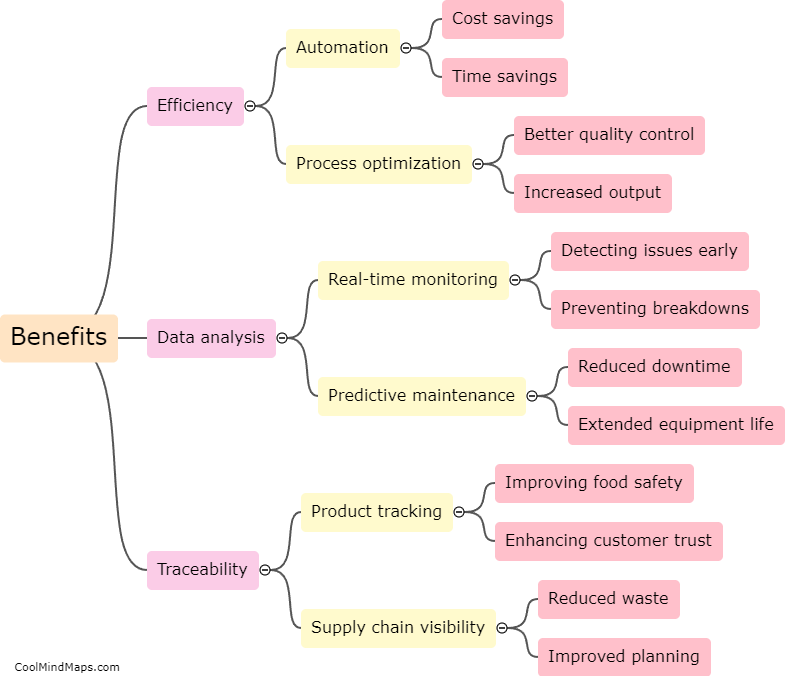

This mind map was published on 31 July 2023 and has been viewed 132 times.