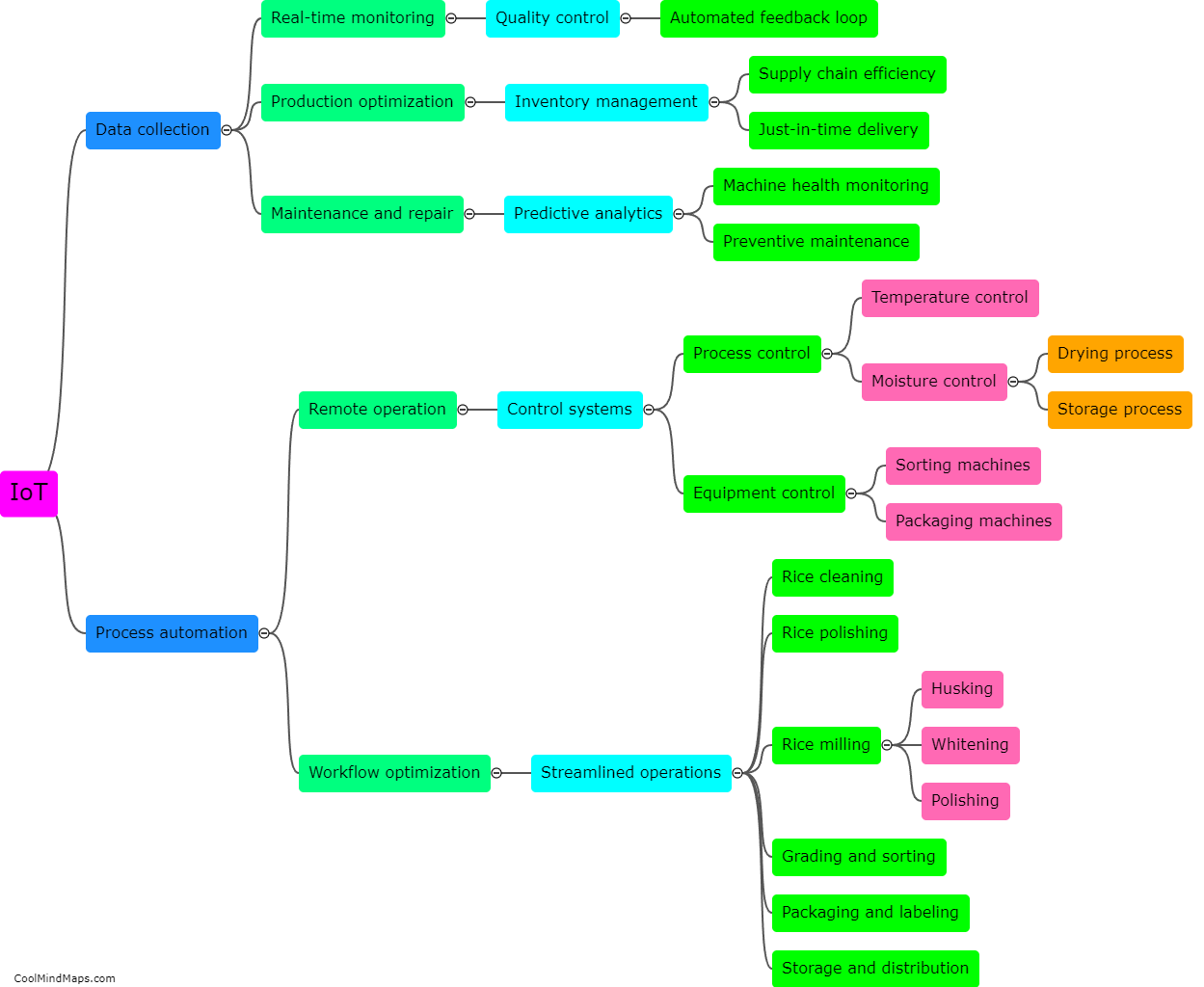

What role does IoT play in rice milling factories?

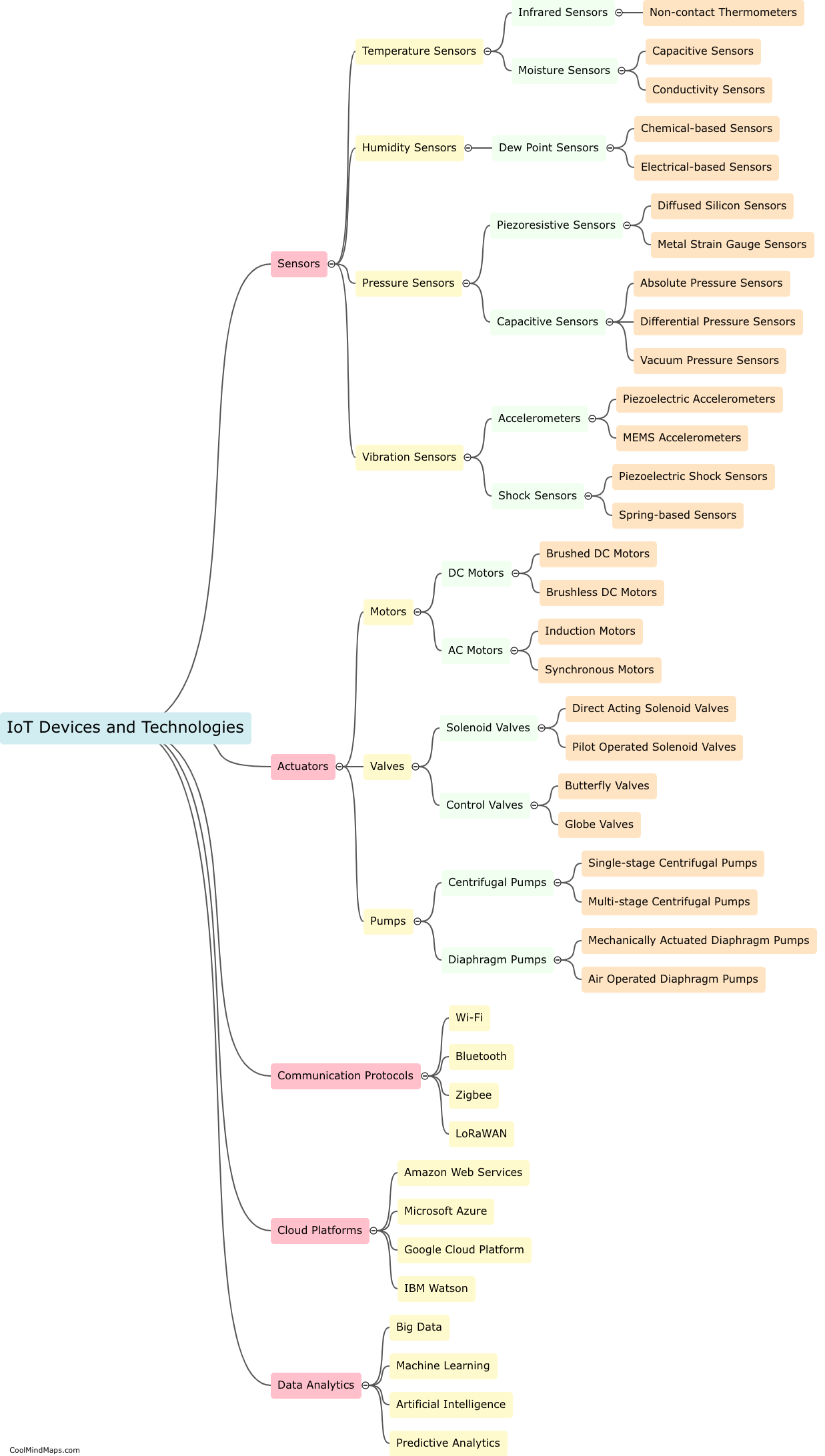

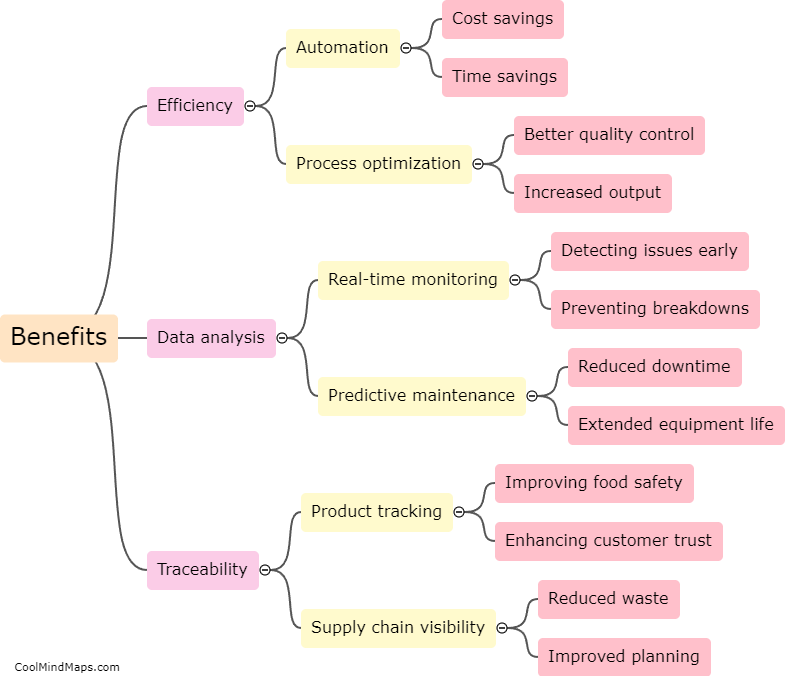

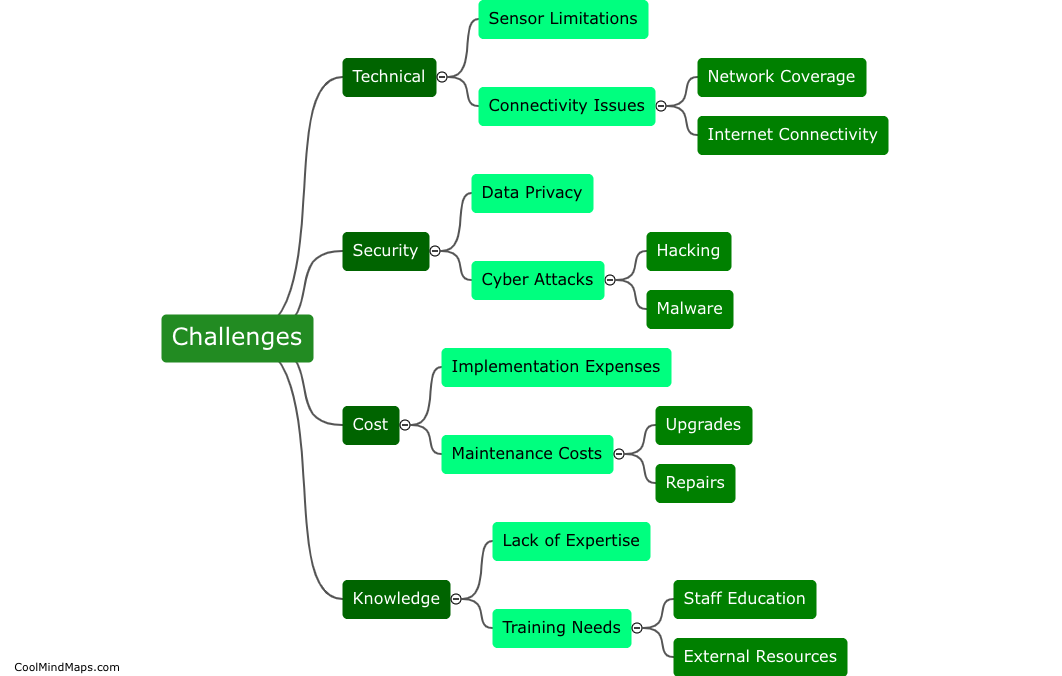

IoT, or the Internet of Things, plays a crucial role in rice milling factories, enhancing their efficiency and productivity. By using interconnected sensors and devices, IoT technology enables real-time monitoring and automation of various processes in the rice milling industry. Sensors placed at different stages of the manufacturing process can collect data on moisture levels, temperature, grain quality, and machine efficiency. This information is then transmitted and analyzed through a connected network, allowing factory managers to make informed decisions and optimize operations. IoT also enables predictive maintenance, as machines can be monitored for signs of wear and tear, minimizing downtime and improving overall equipment effectiveness. Additionally, IoT facilitates traceability in the supply chain, providing detailed information about the origin, quality, and processing of rice to ensure food safety standards are met. Overall, IoT is revolutionizing rice milling factories by streamlining operations, minimizing costs, and improving the quality of the final product.

This mind map was published on 31 July 2023 and has been viewed 130 times.