When was the heat treatment process first used in aircraft manufacturing?

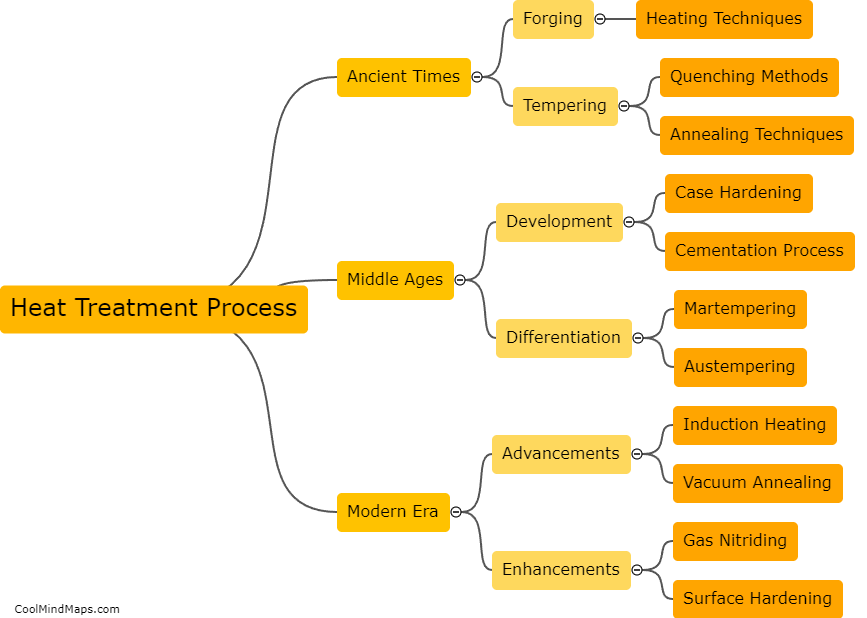

The heat treatment process in aircraft manufacturing was first used in the early 20th century. In the early days of aviation, aircraft components were primarily made from highly ductile and malleable materials such as iron and steel. However, it was soon realized that these materials were not sufficiently strong and durable to withstand the harsh conditions of flight. To enhance the strength and performance of aircraft parts, heat treatment techniques such as annealing, quenching, and tempering were introduced. These processes involve heating the metal to a specific temperature and then cooling it rapidly or gradually to induce specific changes in its microstructure. This revolutionized aircraft manufacturing by enabling the production of stronger, lighter, and more reliable aircraft components, leading to significant advancements in aviation technology.

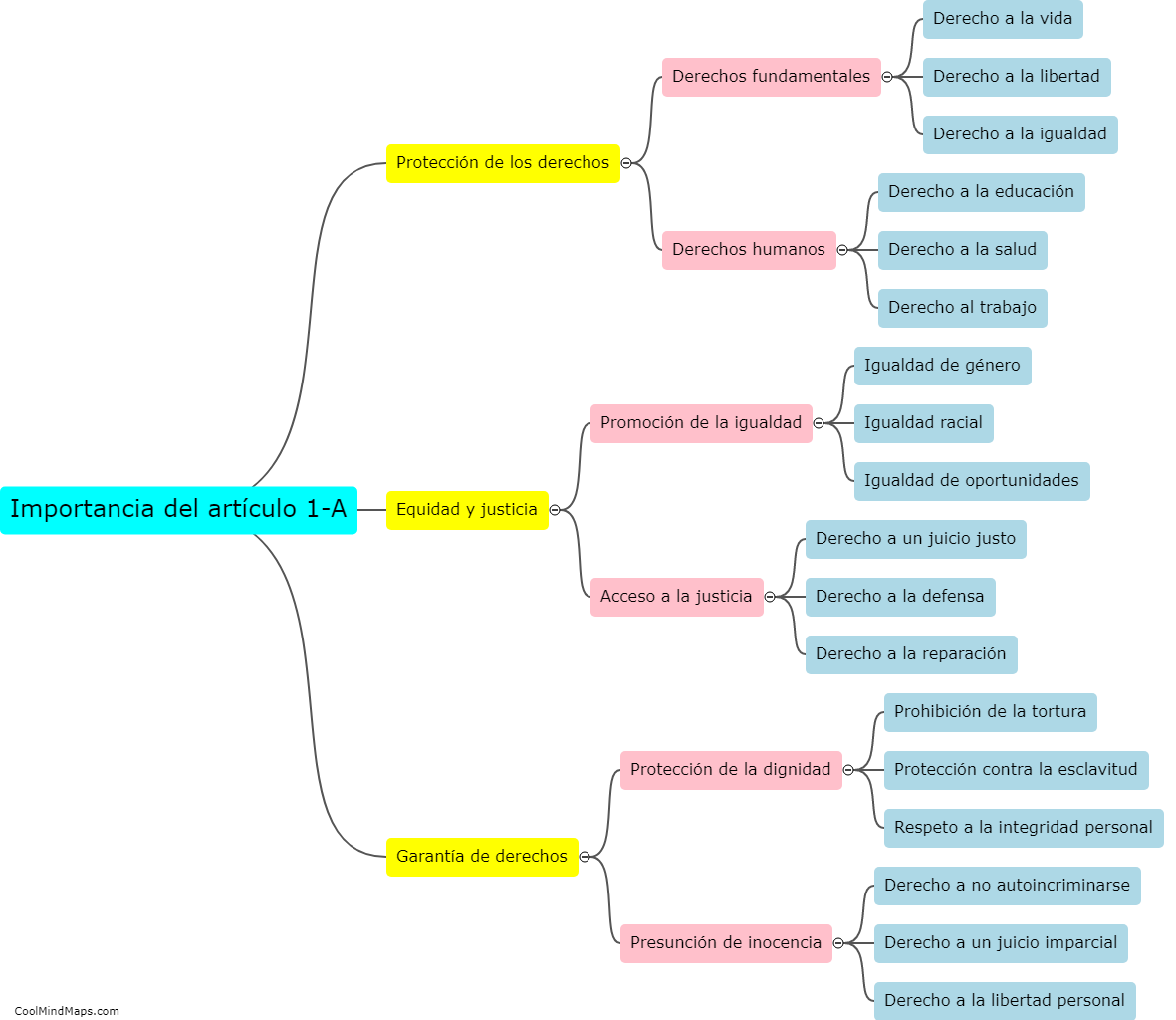

This mind map was published on 16 August 2023 and has been viewed 102 times.